RS4203 Manual

Chapter 11 – Conveyor Assembly Operation and Adjustments

Rev 32, 01/11/13

Copyright © 2013, Tipper Tie, Inc., All rights reserved

76

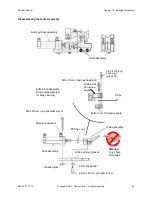

Check the oil level in the lubricator each day and refill as necessary. Do not overfill the lubricator. Use a

high quality SAE #10 pneumatic lubrication oil. Note: The use of oil with a higher viscosity will result in

machine failure.

Warning

: The lubricator cannot be refilled under pressure.

D

o not attempt to remove

the plug while the air pressure is on. Always shut off and lock-out the air supply and

purge pressure from the system before refilling.

To add oil to the lubricator, ensure that the air supply is shut off and locked out and remove the filler plug.

Fill with oil to the level mark and replace the plug. Turn on the air supply to the machine and turn the

needle valve on top of the lubricator until the desired flow is achieved.

Monitor the rate of oil flow into the system using the sight glass on the top of the lubricator. The preferred

flow of oil is one (1) drop of oil for every 15 to 20 machine cycles.

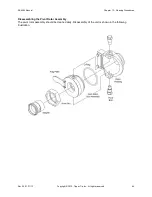

11.5 Trip Paddle

The trip paddle, when installed on the

back guard as shown, is used to initiate

the clip cycle. The trip paddle provides

kip handles for adjusting the position of

the assembly along the guard and for

setting the height of the trip paddle

roller. To operate, the trip paddle must

be set to ON with the touchscreen.