Environmental Pollution

Observe the following instructions to protect workers from danger and to prevent

environmental pollution while performing engine repairs.

Failure to observe the regulations of the relevant authorities violates

environmental pollution regulations and may be subject to legal

penalties.

1. Good ventilation and low humidity should be maintained in the work space.

2. The workspace should be clean and in good order. No flammables are allowed in

the workshop.

3. Smoking is strictly forbidden in the workshop.

4. Workers should wear work clothes, protective goggles, and safety shoes.

5. Workers are not allowed to wear accessories such as necklaces, rings, watches,

and earrings.

6. Start the engine in a well ventilated space to prevent carbon monoxide poisoning.

7. Wait until the engine is properly cooled before starting work otherwise, you may get

burned by the heated engine.

8. Do NOT work on rotating or operating parts once the engine has been started.

9. Discard oil according to the regulations set forth by the relevant authorities.

10. If engine oil or fuel leaks on the floor or is improperly discharged, serious

environmental pollution of sea, river, or underground water may occur.

11. Discard the undiluted anticorrosive agent, antifreeze, filter elements, and cartridges

as special waste.

12. Discard coolant and special waste according to the regulations of the appropriate

authorities.

Use of Genuine Doosan Parts

An engine consists of many parts which are mechanically harmonized. To prevent future

engine faults and ensure best performance for a long period, maintenance and replacement

of expendable parts should be conducted regularly. Use of Doosan genuine parts is

recommended. Using unauthorized or non-factory remanufactured parts may cause critical

damage and faults to engine for which Doosan shall not be held liable.

85

Содержание P185WDOU-T4F (F89)

Страница 2: ......

Страница 3: ...iii...

Страница 4: ......

Страница 10: ...10...

Страница 11: ...Foreword 11...

Страница 14: ...14...

Страница 15: ...Safety 15...

Страница 32: ...Safety Safety Decals continued Below is a summary of safety decals which may be included on your compressor 32...

Страница 33: ...Safety Safety Decals continued Below is a summary of safety decals which may be included on your compressor 33...

Страница 34: ...Safety Safety Decals continued Below is a summary of safety decals which may be included on your compressor 34...

Страница 35: ...Safety Safety Symbols Below is summary of the intended meanings for the symbols used on safety compressor 35...

Страница 37: ...Lifting Transporting and Preparation 37...

Страница 46: ...46...

Страница 47: ...Noise Emission 47...

Страница 53: ...General Data 53...

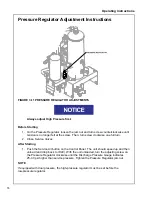

Страница 57: ...Operating Instructions 57...

Страница 77: ...Engine Operation 77...

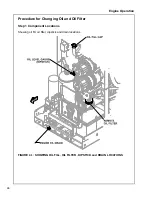

Страница 102: ...Engine Operation Step 4 Drain Engine Oil Showing engine drain location FIGURE 4 4 SHOWING ENGINE OIL DRAIN 102...

Страница 104: ...Engine Operation Step 5 Replacing Oil Filter Showing oil filter location FIGURE 4 5 REPLACING OIL FILTER 104...

Страница 115: ...Lubrication 115...

Страница 120: ...120...

Страница 121: ...Maintenance 121...

Страница 141: ...Troubleshooting 141...

Страница 150: ...150...

Страница 151: ...Compressor Diagnostic Codes 151...

Страница 156: ...156...

Страница 157: ...Engine Fault Codes 157...

Страница 158: ...Engine Fault Codes Engine Fault Code List 158...

Страница 159: ...Engine Fault Codes Engine Fault Code List 159...

Страница 160: ...Engine Fault Codes Engine Fault Code List 160...

Страница 161: ...Engine Fault Codes Engine Fault Code List 161...

Страница 162: ...Engine Fault Codes Engine Fault Code List 162...

Страница 163: ...Engine Fault Codes Engine Fault Code List 163...

Страница 164: ...Engine Fault Codes Engine Fault Code List 164...

Страница 165: ...Engine Fault Codes Engine Fault Code List 165...

Страница 166: ...Engine Fault Codes Engine Fault Code List 166...

Страница 167: ...Engine Fault Codes Engine Fault Code List 167...

Страница 168: ...Engine Fault Codes Engine Fault Code List 168...

Страница 169: ...Preventive Maintenance Schedule PMS 169...

Страница 170: ...Preventive Maintenance Schedule PMS Preventive Maintenance Schedule PMS Preventive Maintenance Schedule 170...

Страница 171: ...Torque Values 171...

Страница 175: ...Wiring Diagrams 175...

Страница 176: ...Compressor and Engine Harness 176...

Страница 177: ...177...

Страница 178: ...178...

Страница 179: ...179...

Страница 180: ...180...

Страница 181: ...Compressor and Engine Control System 181...

Страница 182: ...182...

Страница 183: ...183...

Страница 184: ...P185WDOU Generator Option 184...

Страница 185: ...185...

Страница 186: ...Electrical Parts List 186...

Страница 187: ...187...

Страница 188: ...INTENTIONALLY LEFT BLANK 188...

Страница 189: ...Warranty 189...

Страница 190: ...Warranty Warranty Doosan Portable Power General Warranty Information 190...

Страница 191: ...Warranty Truck Mounted Equipment 191...

Страница 192: ...Warranty Doosan Infracore Federal California Emission Control Systems Limited Warranty for Non Road Engines CI 192...

Страница 194: ......

Страница 195: ......