Noise Introduction

The Compressor for which this Maintenance Log is provided conforms To U.S. EPA

Regulations for Noise Emissions, applicable to Portable Compressors.

The purpose of this book is to provide (1) The Maintenance Performance Schedule for all

Required Noise Emission Controls and (2) Space so that the Purchaser or Owner can record

what Maintenance was done, by whom, where and when. The Maintenance Schedule and

Detailed Instructions on the Maintenance Items are given on the following page.

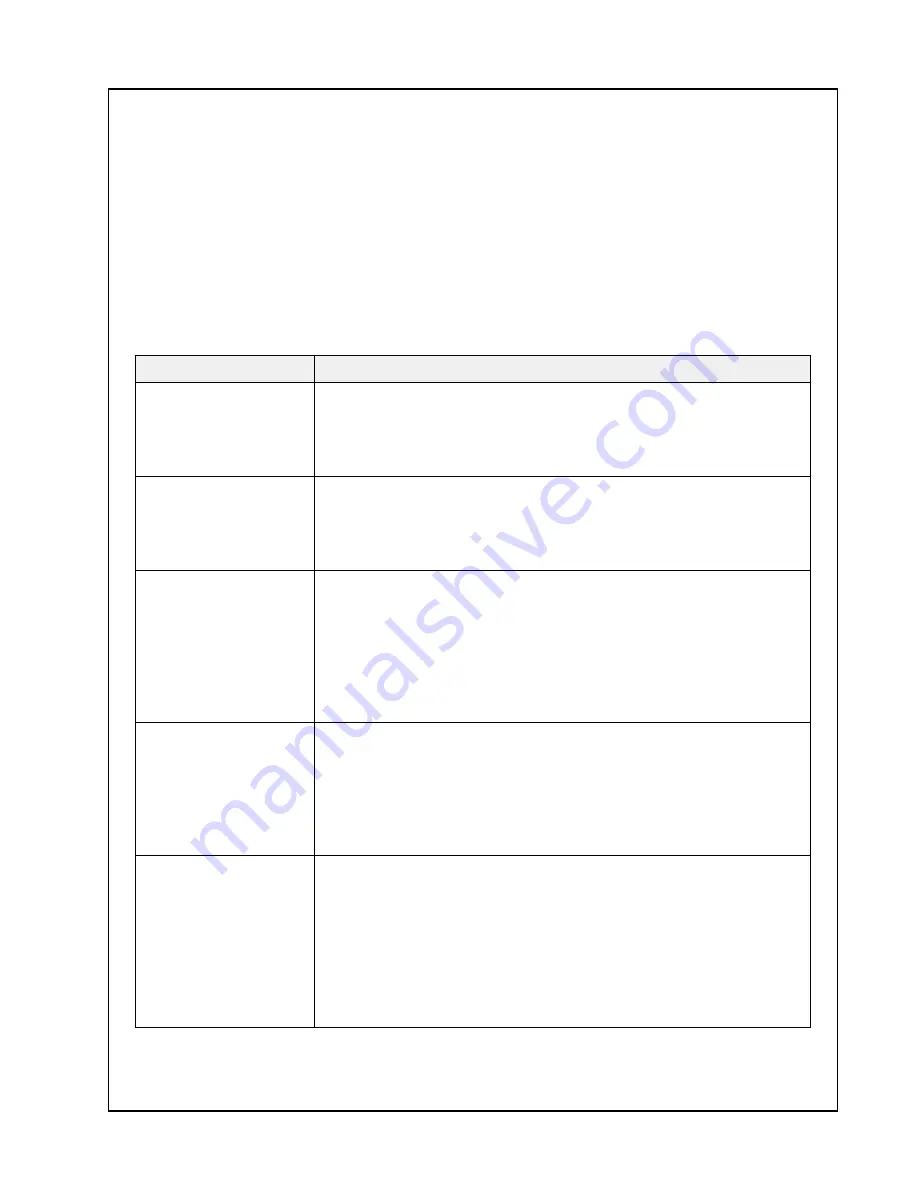

Maintenance Schedule

PERIOD

DESCRIPTION

As Detected

COMPRESSED AIR LEAKS

Correct all compressed air leaks during the first shutdown period

after discovery. If severe enough to cause serious noise problems

and efficiency loss, shut down immediately and correct the leak(s).

As Detected

SAFETY AND CONTROL SYSTEMS

Repair or replace all safety and control systems or circuits as

malfunction occurs. No compressor should be operated with either

system bypassed, disabled, or nonfunctional.

Daily

ACOUSTIC MATERIALS

In daily inspections, observe these materials. Maintain all acoustic

material to its original condition or closely as possible. Repair

or replace all sections that have: 1) sustained damage, 2) have

partially separated from panels to which they were attached, 3) are

missing, or have otherwise deteriorated due to severe operating or

storage conditions.

100 HOURS

FASTENERS

All fasteners such as hinges, nuts, bolts, clamps, screws, rivets,

and latches should be inspected for looseness after each 100

hours of operation. They should be retightened, repaired, or if

missing, replaced immediately to prevent subsequent damage and

noise emission increase.

100 HOURS

ENCLOSURE PANELS

Enclosure panels should be inspected at 100 hour operational

intervals. All panels that are warped, punctured, torn, or otherwise

deformed, such that their noise containment function is reduced,

should be repaired or replaced before the next operation interval.

Doors, access panels, and hatch closures especially, should be

checked and adjusted at this time to ensure continuous seating

between gasket or acoustic material and the mating frame.

49

Содержание P185WDOU-T4F (F89)

Страница 2: ......

Страница 3: ...iii...

Страница 4: ......

Страница 10: ...10...

Страница 11: ...Foreword 11...

Страница 14: ...14...

Страница 15: ...Safety 15...

Страница 32: ...Safety Safety Decals continued Below is a summary of safety decals which may be included on your compressor 32...

Страница 33: ...Safety Safety Decals continued Below is a summary of safety decals which may be included on your compressor 33...

Страница 34: ...Safety Safety Decals continued Below is a summary of safety decals which may be included on your compressor 34...

Страница 35: ...Safety Safety Symbols Below is summary of the intended meanings for the symbols used on safety compressor 35...

Страница 37: ...Lifting Transporting and Preparation 37...

Страница 46: ...46...

Страница 47: ...Noise Emission 47...

Страница 53: ...General Data 53...

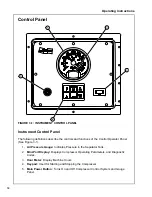

Страница 57: ...Operating Instructions 57...

Страница 77: ...Engine Operation 77...

Страница 102: ...Engine Operation Step 4 Drain Engine Oil Showing engine drain location FIGURE 4 4 SHOWING ENGINE OIL DRAIN 102...

Страница 104: ...Engine Operation Step 5 Replacing Oil Filter Showing oil filter location FIGURE 4 5 REPLACING OIL FILTER 104...

Страница 115: ...Lubrication 115...

Страница 120: ...120...

Страница 121: ...Maintenance 121...

Страница 141: ...Troubleshooting 141...

Страница 150: ...150...

Страница 151: ...Compressor Diagnostic Codes 151...

Страница 156: ...156...

Страница 157: ...Engine Fault Codes 157...

Страница 158: ...Engine Fault Codes Engine Fault Code List 158...

Страница 159: ...Engine Fault Codes Engine Fault Code List 159...

Страница 160: ...Engine Fault Codes Engine Fault Code List 160...

Страница 161: ...Engine Fault Codes Engine Fault Code List 161...

Страница 162: ...Engine Fault Codes Engine Fault Code List 162...

Страница 163: ...Engine Fault Codes Engine Fault Code List 163...

Страница 164: ...Engine Fault Codes Engine Fault Code List 164...

Страница 165: ...Engine Fault Codes Engine Fault Code List 165...

Страница 166: ...Engine Fault Codes Engine Fault Code List 166...

Страница 167: ...Engine Fault Codes Engine Fault Code List 167...

Страница 168: ...Engine Fault Codes Engine Fault Code List 168...

Страница 169: ...Preventive Maintenance Schedule PMS 169...

Страница 170: ...Preventive Maintenance Schedule PMS Preventive Maintenance Schedule PMS Preventive Maintenance Schedule 170...

Страница 171: ...Torque Values 171...

Страница 175: ...Wiring Diagrams 175...

Страница 176: ...Compressor and Engine Harness 176...

Страница 177: ...177...

Страница 178: ...178...

Страница 179: ...179...

Страница 180: ...180...

Страница 181: ...Compressor and Engine Control System 181...

Страница 182: ...182...

Страница 183: ...183...

Страница 184: ...P185WDOU Generator Option 184...

Страница 185: ...185...

Страница 186: ...Electrical Parts List 186...

Страница 187: ...187...

Страница 188: ...INTENTIONALLY LEFT BLANK 188...

Страница 189: ...Warranty 189...

Страница 190: ...Warranty Warranty Doosan Portable Power General Warranty Information 190...

Страница 191: ...Warranty Truck Mounted Equipment 191...

Страница 192: ...Warranty Doosan Infracore Federal California Emission Control Systems Limited Warranty for Non Road Engines CI 192...

Страница 194: ......

Страница 195: ......