Lifting, Transporting and Preparation

Lifting the Compressor

Crushing/compressor damage hazard. Use approved lifting devices as

necessary within sufficient capacity to lift the compressor safely. Refer

to

General Data

for the proper operating weight of the compressor.

Severe injury or death can result if compressor shifts or falls suddenly

during installation procedures.

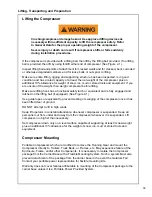

If the compressor is provided with a lifting bail, then lift by the lifting bail provided. If no lifting

bail is provided, then lift by using forklift either end of compressor (See Figure 2-1).

Inspect lifting bail and points of attachment for cracked welds and for cracked, bent, corroded

or otherwise degraded members and for loose bolts or nuts prior to lifting.

Make sure entire lifting, rigging and supporting structure has been inspected, is in good

condition and has a rated capacity of at least the net weight of the compressor plus an

additional 10% allowance for weight of snow, ice, mud or stored tools and equipment. If you

are unsure of the weight, then weigh compressor before lifting.

Make sure lifting hook has a functional safety latch or equivalent and is fully engaged and

latched on the lifting bail (if equipped) (See Figure 2-1).

Use guide ropes or equivalent to prevent twisting or swinging of the compressor once it has

been lifted clear of ground.

DO NOT attempt to lift in high winds

Keep lift operator in constant attendance whenever compressor is suspended. Keep all

personnel out from under and away from the compressor whenever it is suspended. Lift

compressor no higher than necessary.

Set compressor down only on a level surface capable of supporting at least its new weight

plus an additional 10% allowance for the weight of snow, ice, mud or stored tools and

equipment.

Compressor Mounting

Portable Compressors which are modified to remove the Running Gear and mount the

Compressor directly to Trailers, Truck Beds, or Frames, etc. May experience failure of the

Enclosure, Frame, and/or other Components. It is necessary to isolate the Compressor

package from the Carrier Base with a Flexible Mounting System. Such a system Must also

prevent detachment of the package from the carrier base in the event the Isolators Fail.

Contact your portable power representative for flexible mounting kits.

Warranty does not cover failures attributable to mounting of the Compressor package to the

carrier base unless it is a Portable Power Provided System.

39

Содержание P185WDOU-T4F (F89)

Страница 2: ......

Страница 3: ...iii...

Страница 4: ......

Страница 10: ...10...

Страница 11: ...Foreword 11...

Страница 14: ...14...

Страница 15: ...Safety 15...

Страница 32: ...Safety Safety Decals continued Below is a summary of safety decals which may be included on your compressor 32...

Страница 33: ...Safety Safety Decals continued Below is a summary of safety decals which may be included on your compressor 33...

Страница 34: ...Safety Safety Decals continued Below is a summary of safety decals which may be included on your compressor 34...

Страница 35: ...Safety Safety Symbols Below is summary of the intended meanings for the symbols used on safety compressor 35...

Страница 37: ...Lifting Transporting and Preparation 37...

Страница 46: ...46...

Страница 47: ...Noise Emission 47...

Страница 53: ...General Data 53...

Страница 57: ...Operating Instructions 57...

Страница 77: ...Engine Operation 77...

Страница 102: ...Engine Operation Step 4 Drain Engine Oil Showing engine drain location FIGURE 4 4 SHOWING ENGINE OIL DRAIN 102...

Страница 104: ...Engine Operation Step 5 Replacing Oil Filter Showing oil filter location FIGURE 4 5 REPLACING OIL FILTER 104...

Страница 115: ...Lubrication 115...

Страница 120: ...120...

Страница 121: ...Maintenance 121...

Страница 141: ...Troubleshooting 141...

Страница 150: ...150...

Страница 151: ...Compressor Diagnostic Codes 151...

Страница 156: ...156...

Страница 157: ...Engine Fault Codes 157...

Страница 158: ...Engine Fault Codes Engine Fault Code List 158...

Страница 159: ...Engine Fault Codes Engine Fault Code List 159...

Страница 160: ...Engine Fault Codes Engine Fault Code List 160...

Страница 161: ...Engine Fault Codes Engine Fault Code List 161...

Страница 162: ...Engine Fault Codes Engine Fault Code List 162...

Страница 163: ...Engine Fault Codes Engine Fault Code List 163...

Страница 164: ...Engine Fault Codes Engine Fault Code List 164...

Страница 165: ...Engine Fault Codes Engine Fault Code List 165...

Страница 166: ...Engine Fault Codes Engine Fault Code List 166...

Страница 167: ...Engine Fault Codes Engine Fault Code List 167...

Страница 168: ...Engine Fault Codes Engine Fault Code List 168...

Страница 169: ...Preventive Maintenance Schedule PMS 169...

Страница 170: ...Preventive Maintenance Schedule PMS Preventive Maintenance Schedule PMS Preventive Maintenance Schedule 170...

Страница 171: ...Torque Values 171...

Страница 175: ...Wiring Diagrams 175...

Страница 176: ...Compressor and Engine Harness 176...

Страница 177: ...177...

Страница 178: ...178...

Страница 179: ...179...

Страница 180: ...180...

Страница 181: ...Compressor and Engine Control System 181...

Страница 182: ...182...

Страница 183: ...183...

Страница 184: ...P185WDOU Generator Option 184...

Страница 185: ...185...

Страница 186: ...Electrical Parts List 186...

Страница 187: ...187...

Страница 188: ...INTENTIONALLY LEFT BLANK 188...

Страница 189: ...Warranty 189...

Страница 190: ...Warranty Warranty Doosan Portable Power General Warranty Information 190...

Страница 191: ...Warranty Truck Mounted Equipment 191...

Страница 192: ...Warranty Doosan Infracore Federal California Emission Control Systems Limited Warranty for Non Road Engines CI 192...

Страница 194: ......

Страница 195: ......