32

MAINTENANCE

7/20, P65

5. After adding oil, wait more than 5 minutes and check the oil level

again. It takes some time for the oil to drain down to the oil pan.

Changing engine oil

1. Remove the drain plug at the bottom of the engine, and drain all the

old oil. Drain oil will drain easier when the oil is warm.

2. Add new engine oil up to the upper limit of the oil level gauge.

ENGINE LUBRICATING OIL SPECIFICATION

Refer to the

MAINTENANCE SHEDULE

.

ENGINE OIL FILTER ELEMENT

The engine oil filter element should be changed at the engine

manufacturer’s recommended intervals. Refer to the

MAINTENANCE

SHEDULE

.

Replacing the oil filter cartridge

1. Replace the oil filter cartridge after the initial 50 hours of operation

and every 200 hours thereafter.

2. Remove the old oil filter cartridge with a filter wrench.

3. Apply a film of oil to the gasket for the new cartridge.

4. Screw in the cartridge by hand. When the gasket contacts the seal

surface, tighten the cartridge enough by hand. Because, if you

tighten the cartridge with a wrench, it will be tightened too much.

5. After the new cartridge has been replaced, the engine oil level

normally decreases a little. Thus, run the engine for a while and

check for oil leaks through the seal before checking the engine oil

level. Add oil if necessary.

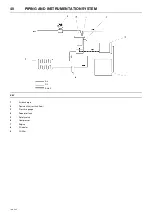

COMPRESSOR LUBRICATING OIL

Refer to the

MAINTENANCE SHEDULE

in this section for service

intervals.

Completely drain the receiver/separator system including the piping

and oil cooler by removing the drain plug(s) and collecting the used oil

in a suitable container.

Replace the drain plug(s) ensuring that each one is secure.

COMPRESSOR OIL FILTER ELEMENT

Refer to the

MAINTENANCE SHEDULE

in this section for service

intervals.

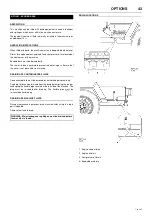

RUNNING GEAR WHEEL BEARINGS

Wheel bearings should be packed with grease every 6 months. The

type of grease used should conform to specification

MIL-G-10924

.

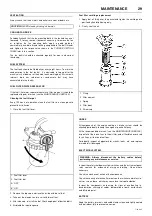

1. Oil filler plug

2. Oil level gauge

A

.

Engine oil level within this range is proper.

CAUTION:

To avaid personal injury ensure that the engine is

stopped before changing the oil filter cartridge.

Allow the engine to cool down sufficiantly, oil can be hot and cause

burns.

1. Oil filter cartridge (Remove with a filter wrench and hand tighten).

NOTE:

If the machine has been operating under adverse conditions,

or has suffered long shutdown periods, then more frequent service

intervals will be required.

WARNING:

DO NOT

, under any circumstances, remove any

drain plugs or the oil filler plug from the compressor lubricating

and cooling system without first making sure that the machine

is stopped and the system has been completely relieved of all air

pressure

(refer to

STOPPING THE UNIT

in the

OPERATING

INSTRUCTIONS

section of this manual).

NOTE:

If the oil is drained immediately after the machine has been

running, then most of the sediment will be in suspension and will

therefore drain more readily.

CAUTION:

Some oil mixtures are incompatible and result in the

formation of varnishes, shellacs or lacquers which may be insoluble.

NOTE:

Always specify PRO-TEC oil for use at all ambient

temperatures above -23°C.

Содержание 7/20

Страница 9: ...DECALS 7 7 20 P65 Engine oil drain Cold Start Procedure...

Страница 18: ...16 GENERAL INFORMATION 7 20 P65 VARIABLE HEIGHT RUNNING GEAR FIXED HEIGHT RUNNING GEAR...

Страница 50: ......

Страница 51: ......

Страница 52: ......