SAFETY

13

7/20, P65

General Information

Never operate unit without first observing all safety warnings and

carefully reading the operation and maintenance manual shipped from

the factory with this machine.

Ensure that the operator reads and

understands

the decals and

consults the manuals before maintenance or operation.

Ensure that the Operation and Maintenance manual, and the manual

holder, are not removed permanently from the machine.

Ensure that maintenance personnel are adequately trained, competent

and have read the Maintenance Manuals.

Make sure that all protective covers are in place and that the canopy/

doors are closed during operation.

The specification of this machine is such that the machine is not

suitable for use in flammable gas risk areas. If such an application is

required then all local regulations, codes of practice and site rules must

be observed. To ensure that the machine can operate in a safe and

reliable manner, additional

equipment such as gas detection, exhaust

spark arrestors, and intake

(shut-off)

valves may be required,

dependant on local regulations or the degree of risk involved.

A weekly visual check must be made on all fasteners/fixing screws

securing mechanical parts. In particular, safety-related parts such as

coupling hitch, drawbar components, road-wheels, and lifting bail

should be checked for total security.

All components which are loose, damaged or unserviceable, must be

rectified without delay.

Air discharged from this machine may contain carbon monoxide or

other contaminants which will cause serious injury or death. Do not

breathe this air.

This machine produces loud noise with the doors open or service valve

vented. Extended exposure to loud noise can cause hearing loss.

Always wear hearing protection when doors are open or service valve

is vented.

Never inspect or service unit without first disconnecting battery

cable(s) to prevent accidental starting.

Do not use petroleum products (solvents or fuels) under high pressure

as this can penetrate the skin and result in serious illness. wear eye

protection while cleaning unit with compressed air to prevent debris

from injuring eye(s).

Rotating fan blade can cause serious injury. Do not operate without

guard in place.

Use care to avoid contacting hot surfaces (engine exhaust manifold

and piping, air receiver and air discharge piping, etc.).

Never operate unit with guards, covers or screens removed. Keep

hands, hair, clothing, tools, blow gun tips, etc. well away from moving

parts.

Compressed air

Compressed air can be dangerous if incorrectly handled. Before doing

any work on the unit, ensure that all pressure is vented from the system

and that the machine cannot be started accidentally.

Ensure that the machine is operating at the rated pressure and that the

rated pressure is known to all relevant personnel.

All air pressure equipment installed in or connected to the machine

must have safe working pressure ratings of at least the machine rated

pressure.

If more than one compressor is connected to one common

downstream plant, effective check valves and isolation valves must be

fitted and controlled by work procedures, so that one machine cannot

accidentally be pressurised / over pressurised by another.

Compressed air must not be used for a direct feed to any form of

breathing apparatus or mask.

High Pressure Air can cause serious injury or death. Relieve pressure

before removing filler plugs/caps, fittings or covers.

Air pressure can remain trapped in air supply line which can result in

serious injury or death. Always carefully vent air supply line at tool or

vent valve before performing any service.

The discharged air contains a very small percentage of compressor

lubricating oil and care should be taken to ensure that downstream

equipment is compatible.

If the discharged air is to be ultimately released into a confined space,

adequate ventilation must be provided.

When using compressed air always use appropriate personal

protective equipment.

All pressure containing parts, especially flexible hoses and their

couplings, must be regularly inspected, be free from defects and be

replaced according to the Manual instructions.

Avoid bodily contact with compressed air.

The safety valve located in the separator tank must be checked

periodically for correct operation.

Whenever the machine is stopped, air will flow back into the

compressor system from devices or systems downstream of the

machine unless the service valve is closed. Install a check valve at the

machine service valve to prevent reverse flow in the event of an

unexpected shutdown when the service valve is open.

Disconnected air hoses whip and can cause serious injury or death.

Always attach a safety flow restrictor to each hose at the source of

supply or branch line in accordance with OSHA Regulation 29CFR

Section 1926.302(b).

Never allow the unit to sit stopped with pressure in the receiver-

separator system.

Materials

The following substances

may

be produced during the operation of this

machine:

•

brake lining dust

•

engine exhaust fumes

AVOID INHALATION

Ensure that adequate ventilation of the cooling system and exhaust

gases is maintained at all times.

WARNINGS

Warnings call attention to instructions which must be followed

precisely to avoid injury or death.

CAUTIONS

Cautions call attention to instructions which must be followed

precisely to avoid damaging the product, process or its surroundings.

NOTES

Notes are used for supplementary information.

WARNING: Under no circumstances should volatile liquids such

as Ether be used for starting this machine.

Содержание 7/20

Страница 9: ...DECALS 7 7 20 P65 Engine oil drain Cold Start Procedure...

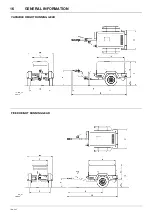

Страница 18: ...16 GENERAL INFORMATION 7 20 P65 VARIABLE HEIGHT RUNNING GEAR FIXED HEIGHT RUNNING GEAR...

Страница 50: ......

Страница 51: ......

Страница 52: ......