7

Donaldson Company, Inc.

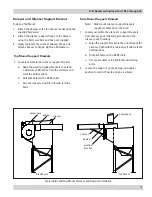

Fan With Inlet Spool Piece Mounted to

Clean Air Outlet Without Weld Nuts

The following instructions are for a fan with an integrated

inlet spool piece being mounted on collectors that do

NOT have weld-nuts on the clean air outlet.

1. Apply the sealer, furnished in the installation

hardware kit, around clean air outlet opening of the

collector. Sealer should be applied in a Figure 8 type

pattern around each bolt hole so that inlet is sealed

from both the outside and the inside of the bolt hole.

2. Remove the inlet spool from fan. Retain the hardware

to for use when fan is reattached to the spool in

Step 5.

3. Position the inlet spool piece onto the collector

surface. Align mounting holes.

4. Bolt the inlet spool piece to the collector clean

air outlet by inserting supplied hardware. Reach

through to secure the nuts on the inside of the clean

air plenum. Apply supplied Loctite on nut.

Fan With Inlet Spool Piece Mounted to

Clean Air Outlet With Weld Nuts

The following instructions are for a fan with an integrated

inlet spool piece being mounted on collectors that have

weld-nuts on the clean air outlet.

1. Apply the sealer, furnished in the installation

hardware kit, around clean air outlet opening of the

collector. Sealer should be applied in a Figure 8 type

pattern around each bolt hole so that inlet is sealed

from both the outside and the inside of the bolt hole.

2. Position TBI fan and spool assembly onto the

collector surface. Align mounting holes.

3. Bolt the TBI fan and spool assembly to the collector

clean air outlet by inserting hardware supplied

through the inlet spool piece and into the weld nut

in the clean air plenum. Be sure to position the

discharge to be free of obstructions and locate so

that the motor’s electrical box will be positioned for

wiring convenience.

4. Inspect the installation prior to starting the fan.

Check for any loose items or debris that could be

drawn into the fan or dislodged by the air discharged

from the fan outlet. Check the interior of the fan as

well. Turn the wheel by hand to check for binding.

5. Complete the electrical connections in accordance

with NEC code and state and local codes. “Bump”

the starter to make sure the motor is rotating in

the proper direction. (Standard TBIs are clockwise

rotation as viewed from the motor endbell.)

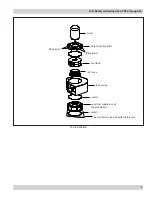

spool

apply loctite to

threads and face

of nut

cabinet (reference)

Steps 3-4

Step 2