BioClass HC

38

19

BOILER MAINTENANCE

Various maintenance operations should be carried out at different intervals of time to keep the boiler

in perfect working order. The yearly maintenance operations should be carried out by personnel

authorised by

DOMUSA TEKNIK

.

19.1

Frequency of maintenance of the boiler and chimney

The most important aspects to be checked are as follows:

Nº

Operation

Frequency

1.

Check the fuel storage.

weekly

2.

Clean the ash in the ash box and ash drawer.

as required

3.

Check the boiler visually.

weekly

4.

Check if the feed auger is correctly calibrated.

as required

5.

Check and clean the boiler fume circuit.

yearly

6.

Check and clean the chimney. The chimney must be free of any obstacles

and have no leaks.

yearly

7.

Clean the burner.

yearly

8.

Check the expansion vessel. It must be full, according to its data plate.

yearly

9.

Check the seal between the burner and the boiler.

yearly

10. Check if the hydraulic circuits are correctly sealed.

yearly

11. Check the brushes of the suction turbine

yearly

11.

Check the water pressure of the boiler.

When the installation is cold

, it

should be between 1 and 1.5 bar.

yearly

NOTE: Depending on the fuel type and weather conditions, it may be necessary to clean the

combustion chamber of the burner at a bigger frequency.

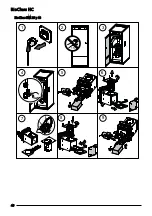

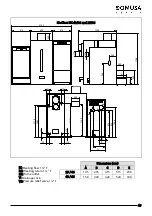

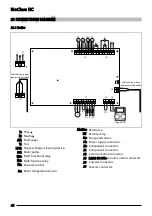

Содержание BIOCLASS HC

Страница 1: ...CGM 04 392 ER 0170 1996 INSTALLATION AND OPERATING INSTRUCTIONS BIOCLASS HC ...

Страница 42: ...BioClass HC 40 BioClass HM 25 y 43 1 2 3 4 5 6 7 8 9 1h PUSH ...

Страница 44: ...BioClass HC 42 BioClass HM 25 and 43 ...

Страница 58: ...BioClass HC 56 25 43 burner ...

Страница 71: ...69 NOTES ...