12

MAINTENANCE & SERvICE

REPLACING ThE hEATER

The heat necessary for the operation of an absorption cooling

unit is supplied by an electric heater mounted in a pocket of

the boiler system.

The refrigerator is equipped with two electrical heaters, one

for 230-240 V AC and one for 12 V DC.

To replace the heater proceed as follows:

Unplug the refrigerator power cord from the 230-

240 volt AC outlet. Disconnect the optional 12 V

DC leads.

Shut off gas valve.

Remove the terminal block cover.

Disconnect the heater leads.

With a pair of pliers unfold the lug holding the lid

of the boiler casing and open the lid.

Remove some insulation wool so that the heater is

accessible.

Turn and lift the heater out of its pocket.

Fit the new heater into the pocket.

Connect the leads and put on the terminal block

cover.

Put back the insulation and close the lid of the

boiler.

PERIODIC MAINTENANCE

Checking the connections

Check all connections in the LP gas system (at the back of

the refrigerator) for gas leaks. The LP gas supply must be

turned on. Apply a non-corrosive bubble solution to all LP

gas connections.

The appearance of bubbles indicates a

leak and should be repaired immediately by a qualified

serviceman.

Checking the LP gas pressure

The LP gas pressure should be checked and the main regula-

tor readjusted if pressure is incorrect. The correct operating

pressure is 2,7 kPa. The correct place to measure the LP gas

pressure is at the test port just ahead of the burner jet.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Cleaning the flue and burner

Inspect the flue baffle. It should be reasonably clean and free

of soot. Heavy soot formation indicates improper functioning

of the burner.

The flue and burner both require cleaning in the following

manner:

Unplug the refrigerator power cord from the 230-

240 volt AC outlet.

Disconnect or shut off the 12 volt DC power to the

refrigerator.

Turn manual shutoff valve to OFF.

Remove cover from the burner housing.

Disconnect the wire from the high voltage elec

-

trode.

Remove the burner mounting screw and remove

the burner assembly.

Remove the wire and flue baffle from the top of

flue tube.

Clean the flue from the top using a flue brush.

Blowing compressed air into the flue will not prop

-

erly clean soot and scale out of the flue tube.

Replace the flue baffle.

Clean burner tube with a brush. Blow out burner

with compressed air.

Before removing burner jet, clean burner area of

soot and scale that fell out of flue tube. Remove

the burner jet.

Soak the jet in wood alcohol and blow it out with

compressed air. Reinstall and tighten burner jet.

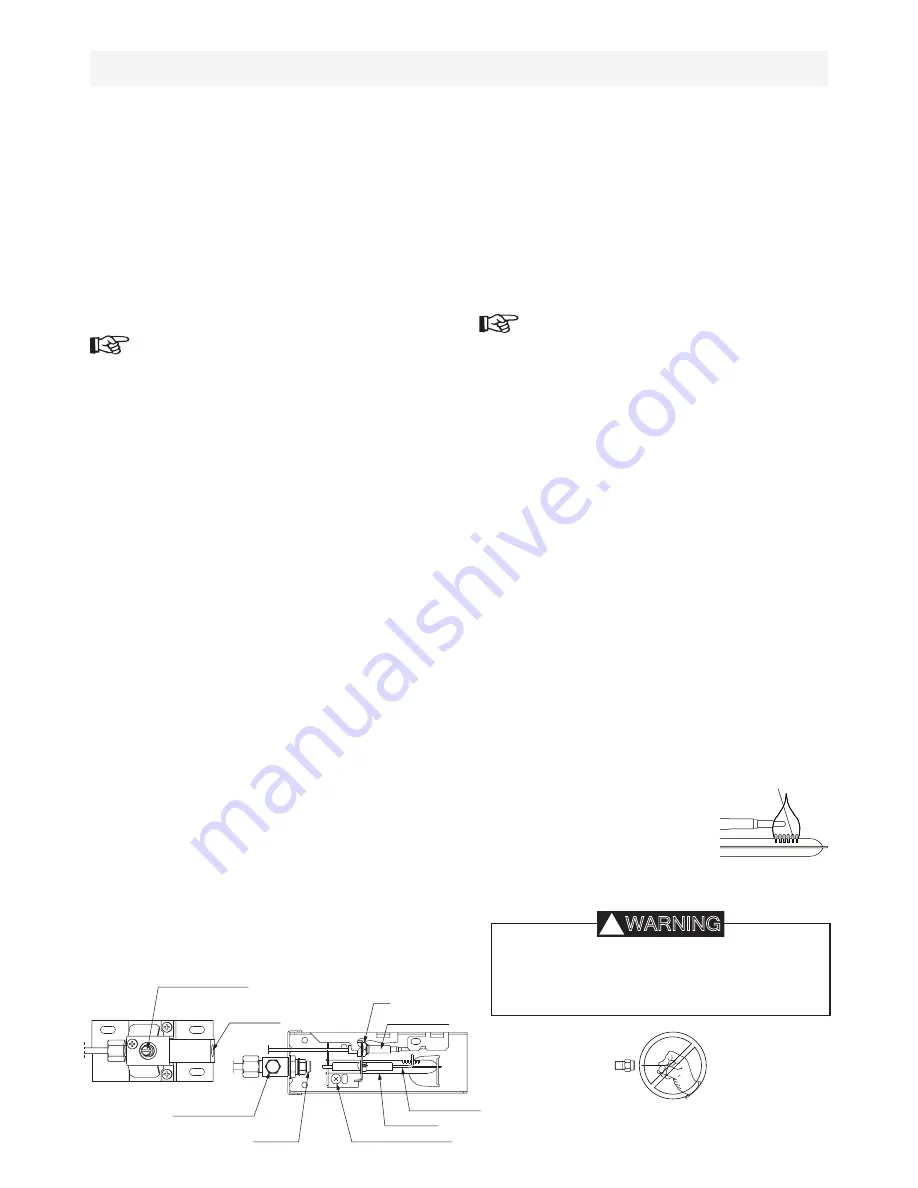

The colour of the flame

shall be clear blue over the

slots of the burner.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Do not use a wire or pin when cleaning the burner

jet as damage can occur to the precision opening.

This can cause damage to the refrigerator or create

a fire hazard.

WARNING

!

Clear blue colour

of flame

Service and maintenance must be done on a regular schedule to keep the refrigerator operating properly, efficiently and safely.

The service should only be performed by a qualified technician who is familiar with LP gas systems and refrigerators.

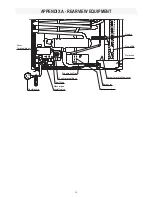

GAs equIpMenT AsseMbly

MANUAL ShUT OFF VALVE

Shown in open position

Use a slotted screwdriver to change position

iNlET FiTTiNG

PRESSuRE TEST PORT

buRNER jET

buRNER MOuNTiNG ScREw

buRNER TubE

SPARk ElEcTRODE

NuT

ThERMOcOuPlE

Содержание RM2453 and

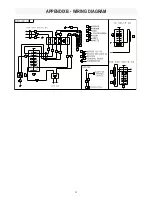

Страница 15: ...15 Appendix B wiring diagram...

Страница 16: ......