maIntenanCe

40

Kohler Engine

These engines are equipped with a replaceable, high

density paper air cleaner element. Some engines

are also equipped with an oiled, foam precleaner

surrounding the paper element.

Check the air cleaner daily or before starting the

engine. Check for a buildup of dirt and debris around

the air cleaner system. Keep this area clean. Also

check for loose or damaged components. replace all

bent or damaged air cleaner components.

Servicing Precleaner

If so equipped, wash and re-oil the precleaner every

25 hours of operation (more often under extremely

dusty or dirty conditions). replace the precleaner

annually, or every 100 hours.

open the door on the blower housing to access

1.

the air cleaner element and precleaner.

Unhook the latch and remove the air cleaner

2.

element assembly for servicing. make sure the

base and the sealing areas are clean before

reassembly.

Wash the precleaner in warm water with

3.

detergent. rinse the precleaner thoroughly until all

traces of detergent are eliminated. Squeeze out

excess water (do not wring). Allow the precleaner

to air dry.

Saturate the precleaner with new engine oil.

4.

Squeeze out all excess oil.

Servicing Paper Element

Check the paper element every 50 hours of operation,

(more often under extremely dusty or dirty conditions).

Clean or replace the element as necessary. replace

the air cleaner element annually, or every 100 hours.

remove the precleaner (if so equipped) from the

1.

paper element.

Gently tap the paper element to dislodge dirt. do

2.

not wash the paper element or use pressurized

air, as this will damage the element. replace a

dirty, bent, or damaged element with a new one.

Handle the new element carefully; do not use if

the sealing surfaces are bent or damaged.

Clean the air cleaner base as required and check

3.

condition.

reinstall the precleaner (if equipped) over the

4.

paper air cleaner element and install on the base.

Secure with the latch.

Close and latch the door.

5.

IMPORTANT INFORMATION

Operating the engine with loose or damaged

air cleaner components could allow unfiltered

air into the engine causing premature wear

and failure.

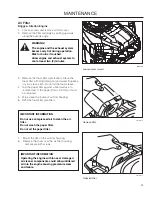

8058-028

1. air cleaner access door

2. air cleaner element

3. latch

4. precleaner (on some models)

Air filter cleaning and replacement

1

4

3

2

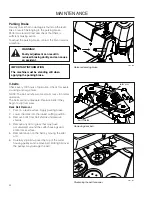

8058-029

Unlatch and remove element

Содержание 966038601

Страница 2: ...2009 HTC All rights reserved Beatrice NE Printed in U S A...

Страница 58: ...schematics 58...

Страница 68: ...68 SERVICE JOURNAL Action Date mtr reading stamp sign...

Страница 69: ...69 SERVICE JOURNAL Action Date mtr reading stamp sign...

Страница 70: ...70 SERVICE JOURNAL Action Date mtr reading stamp sign...

Страница 71: ......

Страница 72: ...P N 115 294527R1 09 21 09...