User Manual in Original

Dok. ref: 550A_GKF_am_sv_210525

DISPERATOR AB

Tel: 08-724 0160

E-mail: [email protected]

Mälarvägen 9, 141 71 Segeltorp

Web page: www.disperator.se

21 / 35

20 / 35

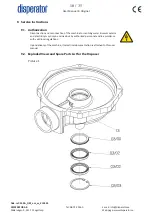

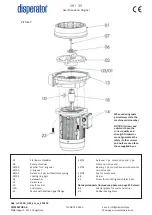

9.3. Overhaul of the Machine

The following checks of the machine must be done in accordance with the table in section 9.6.

“Overhaul and Maintenance Intervals”. The designations in brackets refer the first digit to the picture-

No., and the second digit to the position-No. on the same picture.

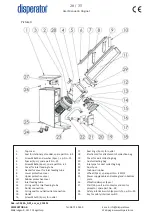

9.3.1. Function Checks of the Interlock Switch (3/28 och 6/1)

The inlet feeding tube is fixed with a knob against the front panel of the glass crusher.

a) Check the function of the interlock switch (key switch) (3/28 and 6/1) by loosening the knob

to release the inlet feeding tube (4/3). The electrical connection must be broken and the

crusher stop when there remain a number of thread turns on the knob, ie before the tube

is released. Also check that the machine idle run stops before the tube can be released and

lifted off.

b) If necessary, fine tune the position of this switch and make sure it is properly fixed.

c) Check that the opening in the front panel and in the interlock switch is in good condition and

clean. If necessary, remove dirt and glass dust using a vacuum cleaner.

d) Ensure that the key (3/29) on the inlet feeding tube (3/11) is properly fixed, and when

mounting the tube on the glass crusher, easily slide into and out of the interlock switch.

9.3.2. Check of the Automatic Function for Collection of Glass Dust

While the glass crusher is running, check its automatic function for collecting glass dust by

placing a thin flat paper over the entire opening of the inlet feeding tube. The paper should

then remain on the tube by the created under-pressure in the crusher. If the paper drops, it leaks

somewhere along the O-ring between the inlet feeding tube and the crushing unit. Then check:

a) that this O-ring is correctly mounted on the tube,

b) that this O-ring is undamaged,

c) that this O-ring´s sealing function not is disturbed by foreign objects,

d) that the dust collection bag (3/20) not is clogged and needs to be replaced. Replacement

dust collection bags are available from stock for immediate delivery from Disperator Co.

9.3.3. Other Checks

a) Check that the rubber parts on the three protection hatches (3/8, 9 och 10) of the inlet

feeding tube are undamaged and seal against the inner wall of the tube.

b) Ensure all four screws (3/5) that fix the crusher against the front panel are tightened.

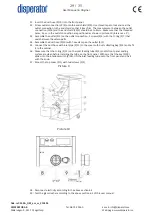

c) Check that the front panel with the crusher is fixed to the cabinet, 6 screws (5/1) on the right

and left inner side of the cabinet.

d) Check that the dust hose (3/22) is sealed and fixed at both ends.

e) Check that the elastic cord (3/18) for attaching the collection bag for crushed glass on the

crusher outlet is intact.

f) Check that the cable and its cable gland (3/25) are fixed in the cabinet base plate.

g) For marine installation check that the cabinet is fixed to the floorboard.

Содержание EXCELLENT 550A-GKF Series

Страница 2: ......