11

Note the direction of rotation

indicated by an arrow on one

side of the disc (direction of

rotation shown on the outside of

the guard housing).

Check the state of cleanliness of

the disc support faces of the

adaptor plates (B and C) and of

the spindle.

The holding screw (D) of the disc

has a right-hand thread.

8

Stopping the machine

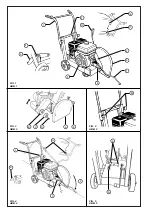

• Raise the lever (K) and pull it towards

you to free the disk from the groove [

SEE

FIG.

4].

• Lock the saw up by releasing the lever

(K).

• Turn off the water supply (G).

• Allow the motor to run idle.

• Switch off the motor (refere to the motor

maintenance manual).

6

Fitting the blade

• Place the machine in an high position.

• Disconnect the water hose connection

from the guard housing.

• Unscrew the nut (E) from the guard

housing [

SEE FIG.

3].

• Remove the guard housing (A).

• Fit the diamond impregnated disc.

• Firmly tighten the screw (D) with the

spanner provided with the machine,

holding the disc steady by hand.

• Replace the protective guard (if this is not

replaced the casing safety switch will

prevent the saw being started).

• Reconnect the water hose (mains with

valve or tank).

• Tighten the nut (E).

Motor off

• Turn off the water tap (G) (from the mains

or from the tank in order to fill it) [

SEE

FIG.

x

4].

• Mark out a line on the ground where a cut

has to be made.

• Position the machine so that the lowered

front guide (F) and the disc are aligned

with the line marked out (disc visble on

the belt side of the housing).

• Start up the motor : refer to the motor

manufacturer’s instructions in the service

manual.

• Allow the motor to warm up.

• Turn on the water supply tap (G) (from

the mains or the water tank).

• Increase the motor speed to full.

• Hold the saw, raise the lever (K) with

your foot and position the disk in contact

with the floor.

• Lower to the depth of cut required (until

there is a click), bearing in mind that each

notch of the lever corresponds to a depth

of 3 cm. Lower slowly to prevent the

engine stalling.

• Gently move the machine forward

ensuring that the front guide and the disc

are always aligned with the line marked

out.

• After use, clean the machine.

• Lubrication : apply a moderate amount of

bearing lubricant to the nipples in the

depth adjustment chassis (depending on

the frequency of use).

• Model with petrol motor (refer to the

motor maintenance manual).

■

Make sure the fuel is topped up.

■

Check the oil level; as the motor often

works at an angle, check it frequently in

the horizontal position that the oil level

is never below the second line on the

gauge.

■

To start up, refer to the motor

instructions.

Take into account the working

conditions from health and safety

point of wiew.

Use only blades marked with a

maximum operating speed

greater than blade shaft speed

"Engine Maintenance" : refer to

the engine maintenance booklet.

Dispose of the old oil as laid

down by the regulations in force.

Motor off

Emergency stop

Operate the switch ( J ) on the

machine's control panel.

Entrust repairs to authorised

dealer only

7

Starting up

Always pay extreme care and

attention to the preparation of

the machine before starting up

Remove all adjustment tools and

wrenches from floor and

machine

Always keep blade guard in

place

Ensure that the water supply is

abundant, when cutting wet.

• There may be several causes responsible

for arresting the disc in the sawing groove

or stopping the machine:

■

Belt tension.

■

Lack of fuel.

■

Advance or lowering too fast, etc.

• In all case, disengage the disc from the

groove and give the machine a complete

check-over.

9

Incidents during sawing

The working area must be

completely cleared, well lit and

all safety hazards removed (no

water or dangerous objects in

the vicinity)

The operator must wear

protective

clothing

appropriate to the work he

is doing. We recommend

that this includes both eye

and ear protection

Any persons not involved in the

work should leave the working

area

The use of ear protection is

mandatory.

5

Check before starting

Please read the instructions for

use prior to operating the

machine for the first time.

Motor off.

• Check the engine oil everyday. Refer to

the engine manual for oil change

schedule. Use :

■

SAE 10W30 motor oil with API class

MS, SD, SE or better for PETROL

engines.

■

API class CD or CE for Hatz diesel.

OIL

English

10

Maintenance (with the

engine stopped)