Arc-Zone.com, Inc.

2091 Las Palmas Drive, Ste. F

Carlsbad, CA 92011 - Tel. 1.760.931.1500

Email: [email protected]

Copyright©2017, Arc-Zone.com®, Inc. All Rights Reserved

6 / 13

Document: DGP-MANUAL-P3-V2 | DGP-PG3-V2 Product User Manual | Released: 7/11 Rev. C

Page 6

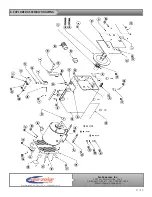

Tip Flat Gage setup:

Once the desired Pin Vise electrode stick-out is determined, set the Tip

Flat Gage as follows:

Initial Gage setup:

1) With electrode extending to the desired length, tighten Pin Vise

lock collar.

2) Loosen Nut D on the Tip Flat Gage.

3) Insert electrode into Tip Flat Gage.

4) Rotate Knob C until the Stop makes contact with electrode tip.

Lock the Stop in place with Nut D.

To duplicate electrode Tip Flat diameter (with Tip Flat Gage depth set per above):

1) Insert electrode into Pin Vise. Extension should be beyond the desired final length.

2) Adjust Pin Vise collar so there is a slight drag on the extended electrode.

3) Insert electrode into Tip Flat Gage. Slide until nose of the Pin Vise contacts the Gage face.

4) Secure electrode in position by tightening Pin Vise collar.

NOTE: Diamond Ground Products (DGP) Diamond Grinding wheels are specifically designed for optimum

wheel life for grinding tungsten electrodes.

GRINDING TECHNIQUES

After the short set up procedure is finished you are ready to prepare

your electrode quickly and easily. Turn the power switch on; slide

the tungsten into the proper collet hole on the universal collet. From

top to bottom the holes are: 3/16”/4.8mm, 5/32”/4.0mm, 1/8”/3.2mm,

3/32”/2.4mm, 1/16”/1.6mm, .040”/1.0mm. Lightly touch the wheel

with the tungsten and rotate it in your fingers in a steady manner until

you have ground to a point or left the proper sized flat you desire. Be

patient and do not gouge the wheel by trying to grind the electrode too

quickly. Gouging the wheel will wear a groove much faster and cause

excessive wear. The approximate recommended grinding times for

each of the diameters is:

3/16” / 4.8mm 100 to 130 seconds

5/32” / 4.0mm 70 to 90 seconds

1/8” / 3.2mm

45 to 60 seconds

3/32” / 2.4mm 20 to 30 seconds

1/16” / 1.6mm 10 to 15 seconds

.040” / 1.0mm 5 to 10 seconds

REMOVING A TIP FROM AN ELECTRODE

After welding, it is beneficial to remove a bad tip before regrinding.

To do this, turn on the power and insert the tungsten in the proper

sized hole from the choices you see on the Tip/Flat Block. Slowly

push the tip against the wheel until the point is removed. Once again,

be patient and do not gouge the wheel. A burr can form if too much

pressure is exerted on the tungsten.