10

/

11

WWW.DDTOP.COM

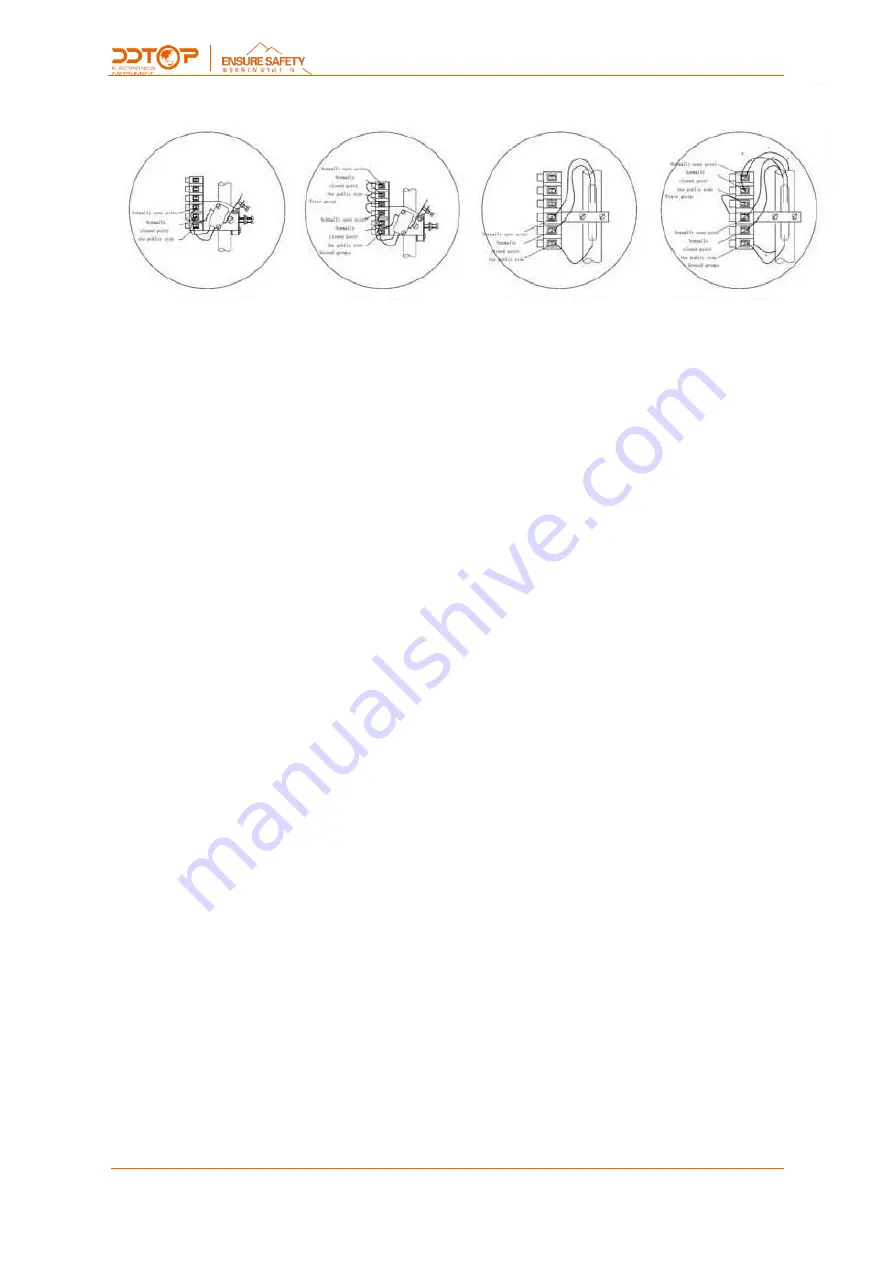

Figure5-1 Figure5-2 Figure5-3 Figure5-4

3. All terminals shall be in good contact with each other, and the nut of outgoing wire shall be

properly pressed to prevent the lead from loosening.

4. Make sure that excess lines do not interfere with the movement of the switch cover or switch

mechanism.

7.3 Debugging Operation Process

1. The instrument should not be subjected to strong vibration and impact, especially on the float

level switch should not be strongly tension pressure, so as to avoid damage to the spring.

2.The instrument may not participate in impactful process tests such as air sweeps performed

before the device is put into production.

3.During commissioning, if water is used as the medium (not actually measured medium), the

following two situations will occur: ρ medium <ρ water and ρ medium>ρ water. If ρ medium <

ρ water, it can be debugged with water. If ρ medium>ρ water, it can't be debugged with water. It

can only be debugged with actual measuring medium.

4. For ρ medium <ρ water When calibrating with water, the alarm position will be lower than the

alarm position required by the actual measurement medium. The difference will be different due to

different working conditions and cannot be calculated by formula.

8. Precautions

8.1 The design density should be the same with the design density. If the density changes, please

contact the manufacturer to confirm whether it can continue to be used.

8.2 During the installing and uninstalling process, the torque tube should be protected as much as

possible to prevent damage.

8.3 The displacer level controller is not suitable for high vibration working condition.

8.4 Medium with viscosity higher than 500mPa/s is not suitable for use with the displacer level

controller.

8.5 Medium with ferromagnetic particles are not suitable for use with displacer level controller.

8.6 After wiring, tighten the power supply cover to prevent the instrument from getting wet.