120 20191-002

Paragon-III

Technical Manual

8

2.5 Electrical

Standard 120 VAC electrical power is required. It should be capable of providing at least 10A to power

Paragon-III (<6A) and ancillary equipment.

2.5.1 Paragon-III Assembly Power

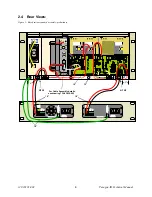

Two distinct power configurations (rear views) are shown in the preceding pages. They are:

•

Paragon-III Base Station Standard Assy (Figure 3).

This configuration is described in paragraph 2.5.1.1 below.

•

Paragon-III Base Station Assy. with 3rd party DC supply (Figure 4).

This configuration illustrates typical wiring variation required when using both a third-party

power supply and an optional DC-powered BDLC-III setup. Refer to Dataradio System

Engineering for further details.

2.5.1.1 Standard Power Supply Configuration

The Radio assembly unit receives separate 13.8 VDC power inputs from a “T800 Slimline” dual

power supply typically rack-mounted right below the main assembly radio chassis.

The T800 is made up of two separate power supply units joined in a single chassis (the second one is

used as a spare):

•

A T807 using convection cooling is rated to 15A nominal at 13.8VDC. It supplies all the radio

modules other than the Power Amplifier.

Normally used at room ambient temperatures, they can operate within their specifications over a

range of –10 to +60 °C.

Note: Internal over-temperature protection shuts down the main transformer above 105 degrees Celsius.

Both power supply modules are internally connected to ground via their individual, rear-connected,

seven-foot standard 120 VAC power cords. Nevertheless, each requires a separate secure electrical

ground connection. Individual grounding tabs are provided next to the power connectors.

Similarly, the Radio Assembly chassis requires a secure ground connection. A threaded grounding

binding post fitted with a knurled binding-nut is provided on the chassis next to DC input 2. Separate

grounding leads with appropriate connectors are supplied (either in the courtesy small-parts kit or

with one end fastened to the equipment.

•

For each of the power supply modules, fit one end of the grounding lead’s push-on connector

onto the grounding tab.

•

For the Radio Assembly chassis, install the grounding lead’s lug over the binding post and firmly

hand-tighten the binding-nut.

•

For each power supply modules

1.

Fit the slotted connector (on the other end of each of the grounding connector) under a

conveniently located screw on the rack frame or other support surface. Scrape away paint

if needed to ensure clean contact.

2.

Apply anti-corrosion compound where paint scraping was done.

3.

Ensure by testing continuity that a secure electrical and mechanical connection is

achieved.

If a –DC rail (0V) is installed as part of the system, the grounding leads may alternatively be fit-

ted to the rail terminal.

Caution:

Improper grounding between power supply case and rack frame may result in harmful voltage potentials and/or miscellaneous power sup-

ply switching noise problems in both receivers and transmitter.