Smart-VS

QUICK REFERENCE GUIDE

Download the Smart-VS Product

Reference Guide by reading

the QR code here or see the

paragraph below.

SUPPORT THROUGH THE WEBSITE

Datalogic provides several services as well as technical

support through its website.

.

For quick access, from the home page click on the

search icon, and type in the name of the product you’re

looking for. This allows you access to download Data

Sheets, Manuals, Software & Utilities, and Drawings.

Hover over the Support & Service menu for access to

Services and Technical Support.

INSTALLATION PROCEDURE

1. Physically mount the Smart-VS device.

2. Make the necessary electrical connections.

3.

Configure the device using the embedded HMI or

the Smart-VS WebApp by connecting to the device

via Ethernet. The WebApp is accessible opening an

Internet browser (Google Chrome is recommended)

and entering the device IP address 192.168.3.100

in the address bar.

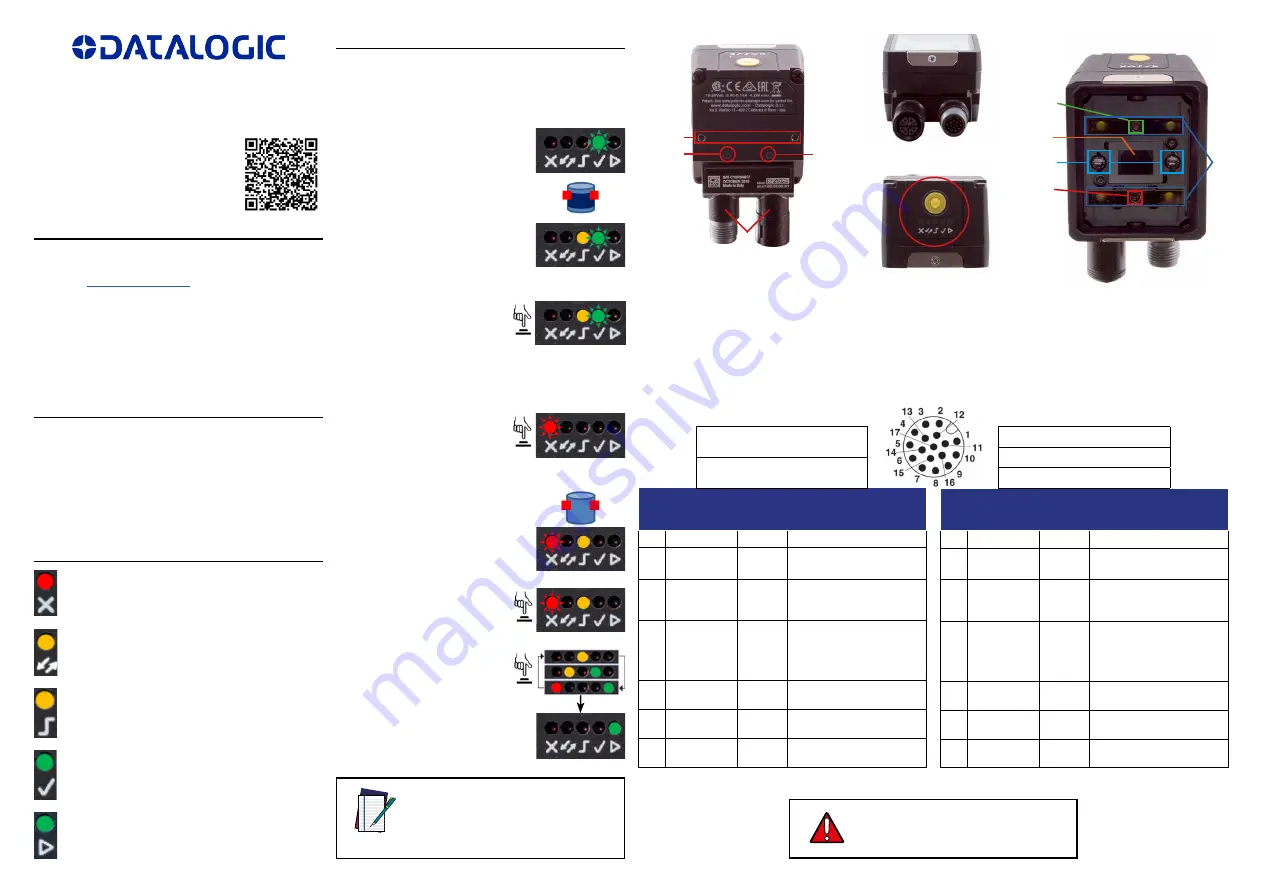

HMI INTERFACE

NO GOOD object

•

in Teach phase: blinking, NO GOOD object

teaching

•

in Run phase: NO GOOD object detected

• for future use

Trigger

• in Teach phase: trigger input status

• in Run phase: trigger received

GOOD object

•

in Teach phase: blinking, GOOD object

teaching

•

in Run phase: GOOD object detected

Run

• steady: device in Run phase

• blinking: Teaching required

BUTTON TEACHING PROCEDURE

The Run LED will blink until the Teaching procedure is

entered (e.g. device factory default).

Long press (> 4s, until the red LED on HMI lights up)

the HMI Button to enter the Teaching procedure.

1.

GOOD objects required to be

taught (green LED and green

spot blink).

2.

Place the GOOD object in

front of the Aiming System.

3. Place the trigger sensor

properly. The Trigger LED

indicates object detection.

4. Short press (< 1s) the HMI

Button to acquire the image.

More than one GOOD

object can be acquired. It

is suggested to acquire one

image per GOOD object

instance. Camera parameters

are auto-adjusted on the first

acquisition only.

5.

Long press (

> 4s, until the red

LED on HMI lights up

) the

HMI Button to start acquiring

NO GOOD objects. Red LED

and red spot start blinking.

6. Place the NO GOOD object

in front of the Aiming System.

Check the Trigger LED.

7.

Short press (< 1s) the HMI

Button to acquire the image.

More than one NO GOOD

object can be acquired.

8. Long press (

> 4s, until the

red LED on HMI lights up

)

the HMI Button to enter the

automatic learning procedure

(LEDs game). At the end,

the device will enter the Run

Phase.

The Teaching procedure can also be

entered when in Run phase: press the

HMI Button for 2s (yellow LED on HMI) for

incremental teaching or 4s (red LED on

HMI) to cancel and re-teach. Refer to the

Product Reference Guide for more details.

NOTE

1

2

3

4

6

7

5

11

8

9

10

1.

Bracket Mounting Holes (2)

2. Power On LED

3. Ethernet Connection LED

4. 90° Rotating Connector Block

5.

HMI Interface

6.

Ethernet Connector

7.

Power - I/O Connector

8.

Lens

9.

LED Aiming System

10. Red Spot (NO GOOD)

11.

Green Spot (GOOD)

12.

White Polarized Illuminators

M12 17-pin Power, and I/O Connector Pinout

(9 stripped wires)

Pin

Color

Name Function

1

2

Brown

Blue

Vdc

GND

PWR supply input v

PWR supply input voltage -

Connector

case

Chassis Connector case provides

electrical connection to

chassis

6

5

13

3

Yellow

Pink

Green

White

I1A *

I1B *

I2A *

I2B *

Trigger Input A

Trigger Input B

Remote Teach A

Remote Teach B

9

Red

O1 **

Data Valid (default is Push-

Pull)

8

Gray

O2 **

GOOD Output (default is

Push-Pull)

16

Black

O3 **

NO-GOOD Output (default

is Push-Pull)

*

Polarity insensitive

**

Short-circuit protected and

software programmable

12

For proper installation, it is recommended

to trim out all unused wires.

WARNING

M12 17-pin Power, and I/O Connector Pinout

(17 stripped wires)

Pin

Color

Name Function

1

2

Brown

Blue

Vdc

GND

PWR supply input v

PWR supply input voltage -

Connector

case

Chassis Connector case provides

electrical connection to

chassis

6

5

13

3

Yellow

Pink

White/Green

White

I1A *

I1B *

I2A *

I2B *

Trigger Input A

Trigger Input B

Remote Teach A

Remote Teach B

9

Red

O1 **

Data Valid (default is Push-

Pull)

8

Gray

O2 **

GOOD Output (default is

Push-Pull)

16

Yellow/Brown

O3 **

NO-GOOD Output (default

is Push-Pull)

CAB-GD03 M12-17P 3M power and

I/O cable, isolated wires (95A900052)

CAB-GD05 M12-17P 5M power and

I/O cable, isolated wires (95A900053)

CAB-GD03 M12 F/L 3M Free wires

CAB-GD05 M12 F/L 5M Free wires

CAB-GD10 M12 F/L 10M Free wires