e

3

0

b

g

3

7

2

.1

0

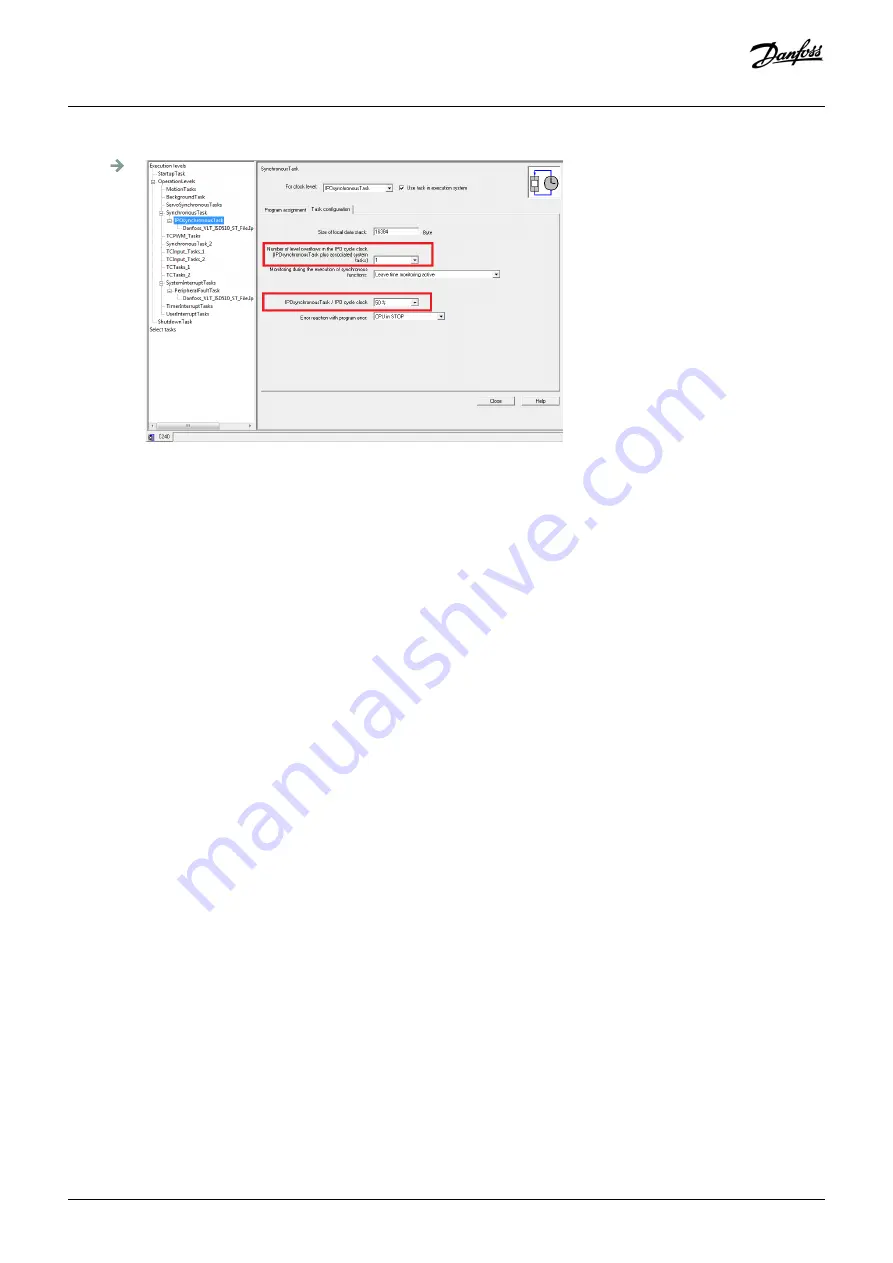

Illustration 101: IPOsynchronousTasks Configuration

8. Expand entry

SystemInterruptTasks

in the tree structure and select the new entry

PeripheralFaultTask

.

9. In the

PeripheralFaultTask

window, activate checkbox

Use task in execution system

.

10. In the

Program assignment

area at the left side of the

PeripheralFaultTask

window, assign the program by selecting it and clicking

on the [>>] button. The program will then be moved to the

Programs used

section on the right side.

11. Click on

Close

to save and compile the settings.

6.15 Programming Guidelines for SIMOTION SCOUT®

Recommendations for implementation:

•

Only assign the variable

InputLogAddress

in the

AXIS_REF_DDS

structure once for each axis at the beginning of the program. Use

the system function

_getLogicalAddressOfIoVariable

to get this address from the I/O variable of the address list. Use the input

address of the module as the I/O variable. Only assign this variable in the 1st PLC cycle for initialization.

•

Initialize parameters that usually do not change only once at the beginning of the program.

•

Only assign the variable

Quality

in the

AXIS_REF_DDS

structure once for each axis at the beginning of the program. Use the system

function

_quality.var-name

. Carry out this check for every PLC cycle.

•

Call up the function blocks

DD_UpdateProcessInput_DDS

and

DD_UpdateProcessOutput_DDS

for every axis to update the process

image partition of inputs and outputs. Call up these function blocks in every PLC cycle.

•

Only create instructions and other program parts between calling up function blocks

DD_UpdateProcessInput_DDS

and

DD_UpdateProcessOutput_DDS

.

•

Call up function blocks that provide status or error information with Enable input at the beginning of the program.

•

Use 1 instance of function block

MC_Power_DDS

for every axis to control its power stage. Call up this function block in every PLC

cycle.

•

Use 1 instance of function block

DD_Power_PSM

for every Power Supply Module (PSM 510) to control the DC-link voltage on the

output lines. its power stage. Call up this function block in every PLC cycle.

•

Use 1 instance of function block

DD_Power_DAM

for every Decentral Access Module (DAM 510) to control the DC-link voltage on

the output lines. its power stage. Call up this function block in every PLC cycle.

•

Use 1 instance of function block

DD_Power_ACM

for every Auxiliary Capacitors Module (ACM 510) to control the DC-link voltage on

the output lines. its power stage. Call up this function block in every PLC cycle

•

Call up function blocks that execute (motion) commands at the end of the program.

•

Do not use any UDTs, POUs, enumerations, or constants starting with the prefix

iDD_

.

•

Do not change the reference to the axis on a function block while it is busy.

Commissioning

Operating Guide | VLT® Multiaxis Servo Drive MSD 510 System

AQ262450196490en-000101 / 175R1170| 133

Danfoss A/S © 2019.10

Содержание VLT MSD 510

Страница 1: ...Operating Guide VLT Multiaxis Servo Drive MSD 510 System...

Страница 2: ......