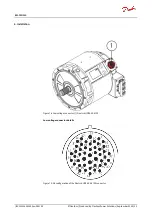

Cooling connections

Make sure that cooling liquid runs freely into and out from the electric machine.

To prevent damage to the cooling connectors, refer to the documentation of the manufacturer for the correct tightening

torque of the cooling liquid nipples.

When selecting cooling liquid nipples, choose nipples that can resist galvanic corrosion.

Connect the electric machine properly to the cooling circuit. Ensure that the coolant ow is equal

or higher than rated and the coolant temperature at the inlet of the machine cooling is lower or

equal to the rated temperature. For more information, see Chapter

product data sheet. Rated values can be found in the electric machine rating plate.

It is recommended to use coolant connector equipped with o-ring seal or to use sealing washer

(for example Usit or Bonded seals) in the connection. In addition, it is recommended to use thread

sealant (Loctite 577 or similar) at the coolant connections to prevent loosening. Loosening can be

caused by vibration or temperature variations.

The electric machines are equipped with at least three PT100 temperature sensors in the windings.

The amount of the sensors depend on the options chosen. The temperature signal(s) can be read

out from the measurement connector of the machine.

Electrical installation

Power connections

High voltage connection

Risk of electric shock. When you work with power connections make sure that electricity is disconnected and that the

rotation of the rotor is prevented.

Mating connectors of the high voltage cables are not part of a standard delivery.

The order of the phases is marked on the power terminal with stickers.

EM-PMI240

6. Installation

32 |

©

Danfoss | Produced By: Danfoss Power Solutions | September 2020

| BC355256345493en-000103

Содержание EM-PMI240

Страница 1: ...User Guide Motor Generator EM PMI240 danfoss com...

Страница 59: ......