AKD 5000

Installation

■

Electrical installation - EMC precautions

The following is a guideline to good engineering

practice, when installing drives. Following these

guidelines is advised, where compliance with EN

50081, EN 55011 or EN 61800-3

First environment

is

required. If the installation is in EN 61800-3

Second

environment,

then it is acceptable to deviate from these

guidelines. It is however not recommended. See also

CE labelling, Emission

and

EMC test results

under

special conditions in the Design Guide for further details.

Good engineering practice to ensure EMC-correct

electrical installation:

•

Use only braided screened/armoured motor cables

and braided screened/armoured control cables. The

screen should provide a minimum coverage of 80%.

The screen material must be metal, not limited to

but typically copper, aluminium, steel or lead. There

are no special requirements for the mains cable.

•

Installations using rigid metal conduits are not

required to use screened cable, but the motor

cable must be installed in conduit separate from

the control and mains cables. Full connection

of the conduit from the drive to the motor is

required. The EMC performance of flexible

conduits varies a lot and information from the

manufacturer must be obtained.

•

Connect the screen/armour/conduit to earth

at both ends for motor cables as well as for

control cables. See also

Earthing of braided

screened/armoured control cables

.

•

Avoid terminating the screen/armour with

twisted ends (pigtails). Such a termination

increases the high frequency impedance of the

screen, which reduces its effectiveness at high

frequencies. Use low impedance cable clamps

or EMC cable glands instead.

•

It is important to ensure good electrical contact

between the mounting plate on which the frequency

converter is installed and the metal chassis of

the frequency converter. This however does

not apply to IP54 units as they are designed for

wall mounting and AKD 5032-5052, 200-240

VAC in IP20/Nema1 enclosure.

•

Use starwashers and galvanically conductive

installation plates to secure good electrical

connections for IP00 and IP20 installations.

•

Avoid using unscreened/unarmoured motor or

control cables inside cabinets housing the drive(s),

whenever this can be avoided.

•

An uninterrupted high frequency connection

between the frequency converter and the motor

units is required for IP54 units.

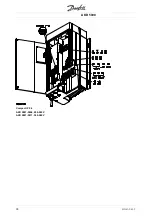

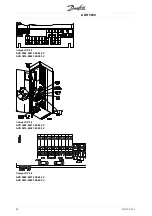

The illustration shows an example of an EMC-correct

electrical installation of an IP 20 frequency converter;

the frequency converter has been fitted in an installation

cabinet with an output contactor and connected

to a PLC, which in this example is installed in a

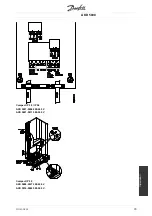

separate cabinet. In AKD 5032-5052, 200-240

VAC in Nema 1/IP20 enclosure screened cables

are connected by using EMC conduits to ensure

proper EMC performance. See illustration. Other

ways of making the installation may have as good

an EMC performance, provided the above guide

lines to engineering practice are followed.

Please note, that when the installation is not carried

through according to the guideline as well as when

unscreened cables and control wires are used, some

emission requirements are not complied with, although

the immunity requirements are fulfilled. See the section

EMC test results

in the Design Guide for further details.

MG.50.R3.02 -

31

Содержание AKD 5001

Страница 12: ...AKD 5000 Introduction Ordering form AKD 5000 Series Typecode MG 50 R3 02 11 ...

Страница 25: ...AKD 5000 Type F IP54 MG 50 R3 02 24 ...

Страница 29: ...AKD 5000 Compact IP 54 AKD 5001 5006 200 240 V AKD 5001 5011 380 500 V MG 50 R3 02 28 ...

Страница 33: ...AKD 5000 MG 50 R3 02 32 ...