DD2546969 Rev 0

13 May 2013

PO Box 5128 201 Daktronics Drive, Brookings, SD 57006-5128

tel: 800-325-8766 fax: 605-697-4700

www.daktronics.com

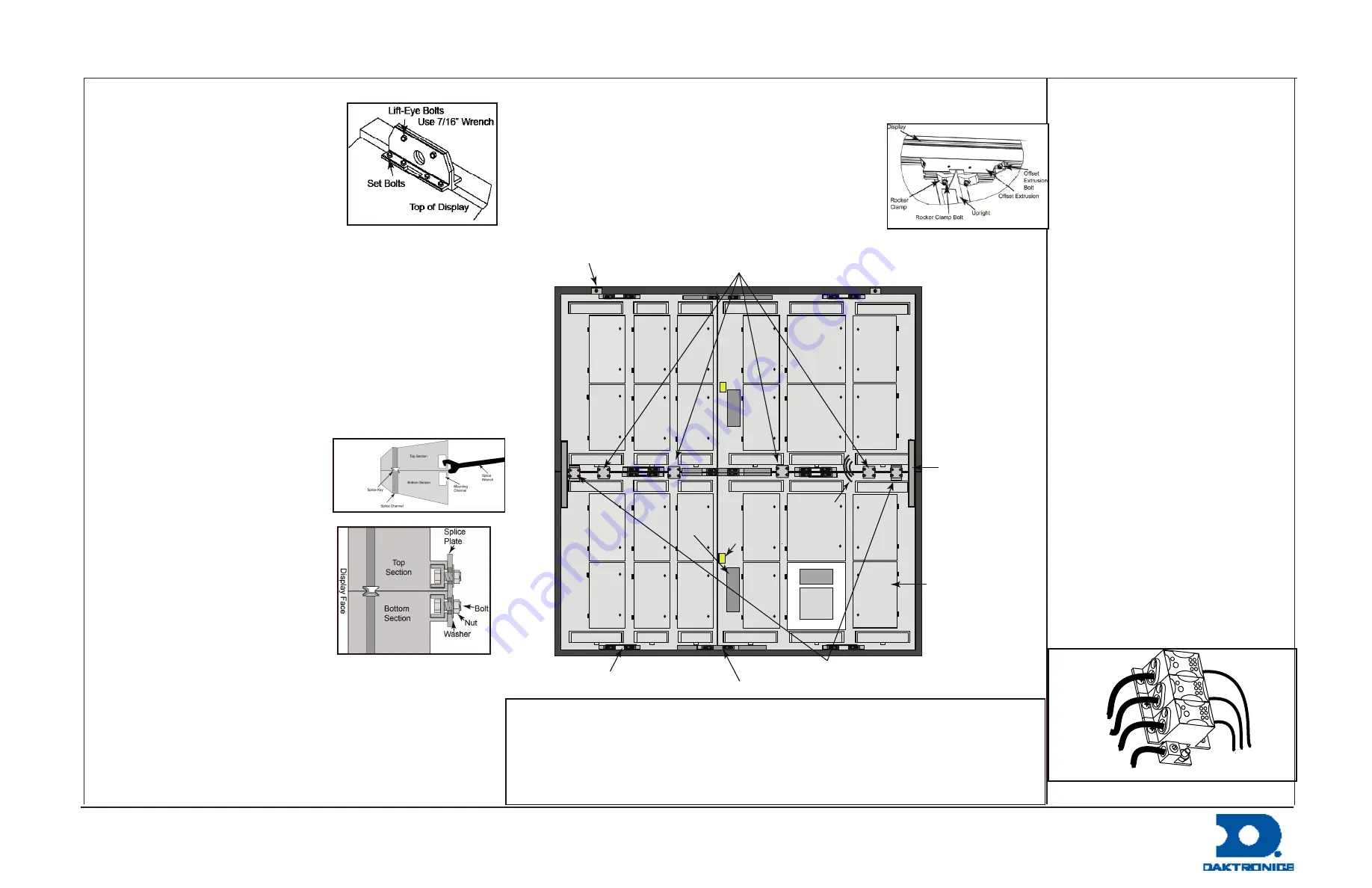

1.

Verify lift-eye and set bolts are

secure.

2.

Identify the display sections.

3.

If there is a horizontal splice required

(side by side), install a C-shaped

splice plate at the top and bottom

of one of the display sections so it

can catch and engage the second

section. Note: There are examples of

installation hardware installation locations on the back of

this quick guide. The hardware installation location can also

be located on the shop drawing.

4.

Lift a display section.

5.

Carefully guide and pull the two display sections together.

6.

Install the required nuts and bolts to secure the two display

sections together.

7.

Ensure the LEDs align between the two display sections.

8.

Repeat

Steps 3 - 7

for all horizontal splices.

9.

Attach the crane to the lift-eyes in the top section.

10.

Remove the bolts that hold the lift-eyes in the bottom section

together and to the display. Slide the two pieces of the lift-

eye past each other and lift them out of the channel.

11.

Lift the top section.

12.

Lower the top section on to the

bottom section.

13.

Use the splice wrench to align the

display sections.

14.

Verify the LEDs on both display

sections align with each other.

15.

Install and evenly distribute the flat

splice plates along the back of the

display.

16.

Install the C-shaped splice plates at

each end of the display.

17.

Install the vertical splice tubes so

they are split evenly between the

top and bottom display sections.

18.

Measure the uprights on the

structure head and install the

mounting clamps on the back of the display to match the

spacing.

19.

If needed, relocate the DMP and the ISP enclosure to the

alternate location to avoid structural interference when

installed.

20.

Install the display borders.

21.

Connect the signal splice cables between the display sections

(A to A, and B to B).

1.

Refer to the display riser

diagram for required power.

2.

Run conduit from the main

distribution panel to the

display power entrance(s).

3.

Loosen the six screws that

secure the power entrance

cover and remove the cover.

4.

Feed the power cable through

the conduit into the power

entrance.

5.

Connect the green ground

wire to the ground lug at the

bottom of the power entrance

box and tighten to 45 in-lbs.

6.

Connect power line 1 to Line

1 on the tap and tighten to 57

in-lbs.

7.

Connect power line 2 to Line

2 on the tap and tighten to 57

in-lbs.

8.

Connect the neutral line to the

neutral tap and tighten to 57

in-lbs.

9.

Verify the breakers for the

control equipment and surge

suppressor are on.

10.

Verify the breaker for the

Backlit ID is off unless there is

a backlit ID.

11.

Replace and secure the power

entrance cover.

Display Installation

Electrical Installation

Line 1

Line 2

Neutral

Ground

To Display

4203 Series Digital Billboard Installation Quick Guide

Note

•

There are no display filters on the 4203 series. Filter retrofit kits are available for displays in

highly corrosive environments. Work with the Account Service Manager if a filter retrofit kit is

needed.

•

If your display has an external control enclosure, refer to the quick guide shipped with the

enclosure for external enclosure installation.

•

For full installation instructions, refer to the installation manual located in the spare-parts box.

22.

Install the webcam and webcam arm.

23.

Connect the webcam Ethernet cable to the back of the display (below the power

entrance box) and connect the green grounding cable to the back of the display.

24.

Lift the display to the structure.

25.

Lower the display until it rests on all the display

ledger brackets. If needed, insert metal shims until the

display is resting on all ledger brackets.

26.

Connect and secure all mounting clamps to the

uprights.

Note:

Tighten all mounting hardware to 75

ft-lb.

27.

Remove the crane support.

Flat Splice Plates

“C” Splice Plates

Vertical

Splice

Tubes

Power Entrance

Splice Cables

Lift-Eye

Mounting Clamp

Horizontal Splice Tubes

DMP

ISP

Alternate

DMP and

ISP Bay

Surge