SiME332106E

Check

Part 6 Service Diagnosis

273

Note(s)

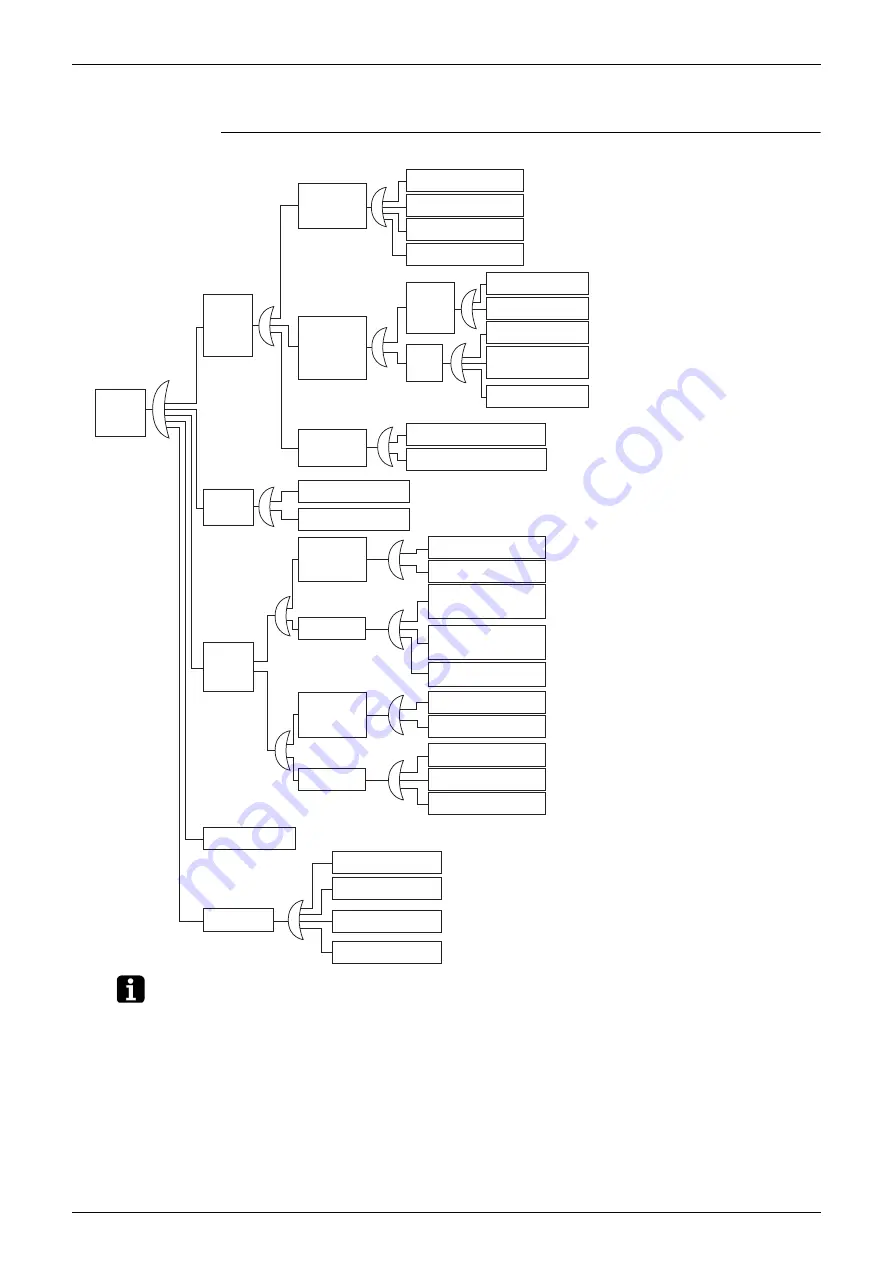

6.3 Superheat Operation Check

CHECK 3

Referring to the Fault Tree Analysis (FTA) shown below, probe the defective points

Abnormal piping length

Bent or crashed pipe

(Including moisture choke)

Stop valve closed.

Defective valve coil

Defective valve body

Defective valve coil

Defective valve body

Are the coil resistance and insulation normal?

Refer to

CHECK 7 .

Does the piping length fall in the permissible range?

Conduct visual checks.

Eliminate moisture by vacuum operation. (Refer to

CHECK 8 .

)

Check if the stop valve is open.

Defective

discharge

pipe

temperature

control

Defective hot

gas bypass

control

Hot gas circuit clogging

Defective solenoid

valve coil

Defective solenoid

valve body

Defective main PCB

Defective main

PCB

Defective valve coil

Defective low

pressure sensor

Defective subcooling

heat exchanger outlet

thermistor

Defective valve

body

Defective

subcooling

electronic

expansion

valve control

Superheat due to

shaft damage

Superheat due to

defective compressor

Defective indoor

unit electronic

expansion valve

Defective

control

Defective

control

Defective

outdoor unit

electronic

expansion valve

Defective four

way valve

operation

[In cooling only]

(

1)

Compressor

overheat

Refrigerant

shortage

High pipe

resistance

Defective

superheating

degree

control.

[In cooling]

If the indoor unit

electronic

expansion valve is

throttled too much:

(

2)

[In heating]

If the outdoor unit

electronic

expansion valve

excessively

throttled: (

3)

Temperature

increase of

discharge

pipe

Defective

subcooling

electronic

expansion

valve

Are the coil resistance and

insulation normal?

Is the connector properly connected?

Are the thermistor resistance characteristics

normal?

Are the voltage characteristics normal?

Is the pressure value checked with the

Service Checker corresponding to the

measurement value of the pressure sensor?

Check if the piping temperature connected

to the four way valve is normal.

Four way valve is in the

middle position.

Leak from hot gas bypass

valve

Defective

control

Defective gas pipe

thermistor of indoor unit

Defective thermistor for

indoor unit liquid pipe

Defective main

PCB

Defective low pressure

sensor

Defective suction pipe

thermistor

Defective main

PCB

Are the voltage characteristics normal?

Is the pressure value checked with the Service

Checker corresponding to the measurement

value of the pressure sensor?

Is the connector properly connected?

Are the thermistor resistance characteristics normal?

Is the connector properly connected?

Are the thermistor resistance characteristics normal?

Are the coil resistance and insulation normal?

Are the coil resistance and insulation normal?

Is the connector properly connected?

Are the thermistor resistance characteristics normal?

1. Refer to “Low pressure protection control” for hot gas bypass control.

2. “Superheating temperature control” in cooling is conducted by indoor unit electronic

expansion valve.

3. Superheating temperature control in heating is conducted by outdoor unit electronic

expansion valve (main).

Содержание VRV RXYMQ-A Series

Страница 1: ...Service Manual RXYMQ A Series Heat Pump 50 60 Hz SiME332106E...

Страница 283: ...SiME332106E Check Part 6 Service Diagnosis 277 PCB and Circuit Diagram U V W L3B L2B L1B P1 P2 N32...

Страница 296: ...SiME332106E 290 Part 7 Appendix 1 Wiring Diagrams 291 1 1 Outdoor Unit 291 1 2 VRV Indoor Unit 293 Part 7 Appendix...

Страница 297: ...SiME332106E Wiring Diagrams Part 7 Appendix 291 1 Wiring Diagrams 1 1 Outdoor Unit RXYMQ4AVMK C 3D133942...

Страница 298: ...Wiring Diagrams SiME332106E 292 Part 7 Appendix RXYMQ4 5 6AYFK C 3D133944A...

Страница 303: ...SiME332106E Wiring Diagrams Part 7 Appendix 297 FXMQ40 50 63 80 100ARV1 3D127112 04 59...