Troubleshooting

Si-93

36

Troubleshooting

1.6

Damper System Error (Alarm)

Remote Controller

LCD Display

Error Code

666

6AAA

A

Inspection

—

Unit No.

5

LED Indication

Remote Controller

4

Main Unit

5

Error Detection

Method

Measurement of damper motor limit ON/OFF time.

Error Generating

Conditions

■

When damper motor limit switch 1 (or 2) remains ON (or OFF) for more than a certain time duration

after ventilation mode is changed.

■

When damper motor limit switch 1 (or 2) repeats ON/OFF operations after damper motor 1 (or 2) stops.

Possible Causes

■

Faulty damper motor or limit switch

■

Broken wire in cable

■

Faulty contact in connector (including relay connector)

■

Faulty control PCB assembly

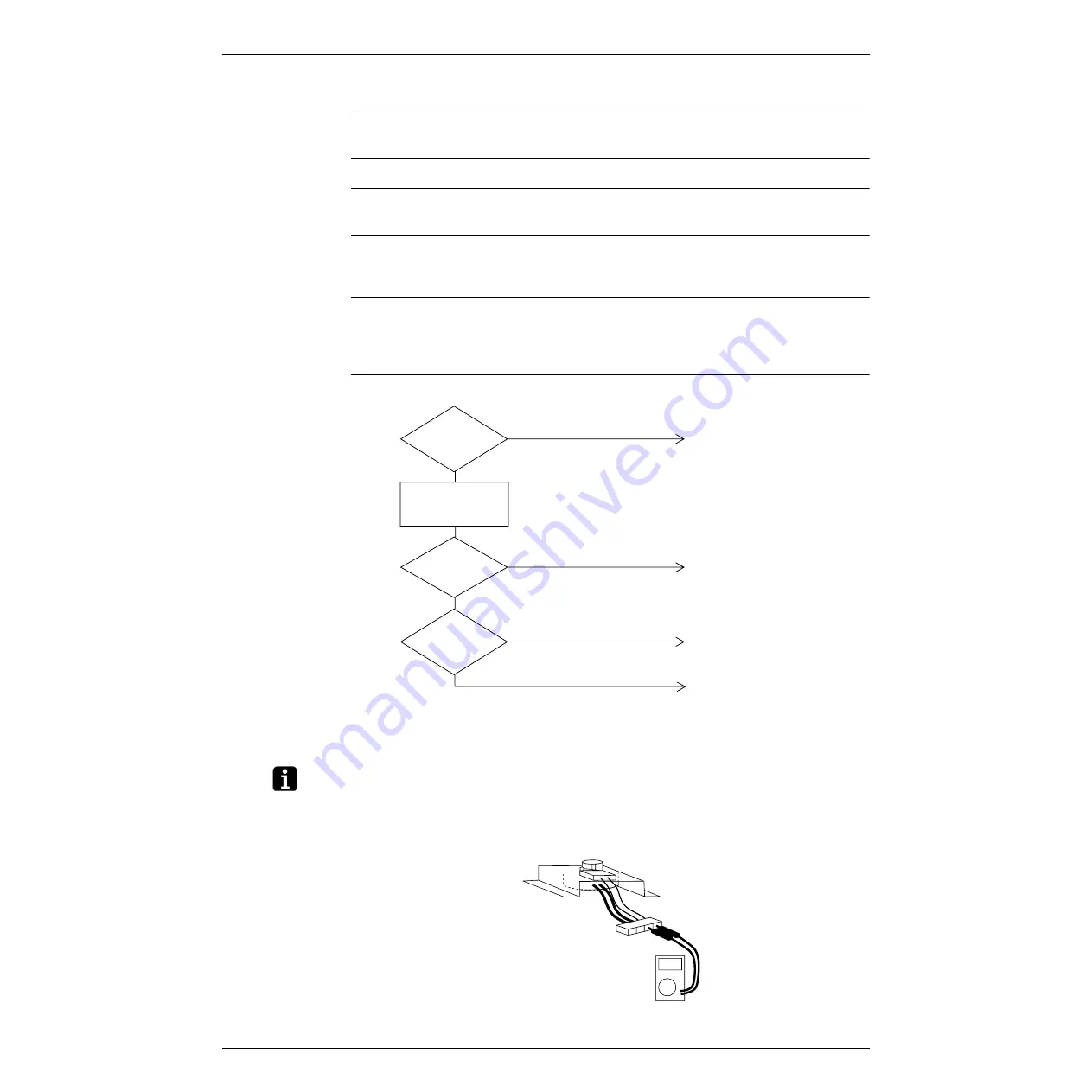

Troubleshooting

Note:

Note 1:

■

Place tester probes on connectors of limit switch. Move switch by hand and check continuity. If tester

indicates 0

Ω

when limit switch turns on, and infinity when it turns off, limit switch is normal.

■

Place tester probes on connectors of damper motor and check resistance. If tester indicates approx. 17

k

Ω

in 200-V model, damper motor is normal.

Check connectors

(X3A or X4A) (X5A or

X6A) on PCB assembly

of damper motor unit.

Is

damper

motor unit

operating

normally?

Note 1

YES

YES

YES

Connect relay connector.

Connect connectors.

Replace damper motor unit.

Replace control PCB assembly.

Is

relay

connector of

damper motor unit

connected?

NO

(HF005)

NO

Are connectors

connected?

NO

Check resistance and voltage

(HL029)

Содержание VAM 500EJ

Страница 1: ...Heat Recovery Ventilation Applied Models VAM 500EJ VAM 800EJ VAM1000EJ VAM2000EJ SiE 93 Service Manual...

Страница 5: ...Si 93 iv Table of Contents...

Страница 7: ...Introduction Si 93 vi 1 1 1 Cautions in Repair Warning...

Страница 8: ...Si 93 Introduction vii...

Страница 10: ...Si 93 General Constructions 1 Part 1 General Constructions 1 General Constructions 3 1 1 Explanation 3...

Страница 11: ...Si 93 2 General Constructions...

Страница 15: ...Si 93 6 Operation...

Страница 21: ...Si 93 12 Maintenance...

Страница 27: ...Si 93 18 Control Functions...

Страница 35: ...Si 93 26 Circuit Operations...

Страница 39: ...Si 93 30 Troubleshooting...

Страница 59: ...Troubleshooting Si 93 50 Troubleshooting...

Страница 61: ...Si 93 52 Supplementary Explanation...

Страница 72: ...Si 93 Appendix 63 Part 8 Appendix 1 Appendix 65 1 1 Wiring Diagram 65...

Страница 73: ...Si 93 64 Appendix...

Страница 74: ...Si 93 Appendix Appendix 65 1 Appendix 1 1 Wiring Diagram VAM500EJVE VAM800EJVE VAM1000EJVE...

Страница 75: ...Appendix Si 93 66 Appendix VAM2000EJVE...

Страница 79: ...Si 93 iv Index...

Страница 81: ...Si 93 vi Drawings Flow Charts When no indication is displayed on remote controller 45 Wiring Diagram 65...