EWAP400~540MBYNN

Packaged air-cooled water chillers

4PW22678-1B

Installation manual

6

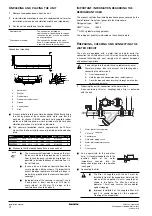

Setting the adresses on the digital controller

Set the addresses on the PCB by means of DIP-switches according

to the drawing below:

Where to find the DIP-switches of the digital controller

Important

Be sure to attach – in case of common leaving water control – the

optional temperature sensor.

Cable for remote digital controller

See remote digital controller in the operation manual.

1

A remote digital controller can be connected to the PCB inside

the unit by means of a 6-ray cable and a connector located on

the rear side of the remote digital controller in case you prefer to

operate the unit from a distance. You are allowed to use a cable

of up to 600 metres. Specifications of the cable: 6-ray telephone

cable with a maximum cable resistance of 0.1

Ω

/m.

2

For units in a DICN configuration, the digital controllers of the

units can be installed remotely at a distance of up to 60 metres

by using a 6-ray telephone cable with a maximum cable

resistance of 0.1

Ω

/m.

Setting the adresses on the remote digital controller

When a remote digital controller is used, the adress has to be set by

means of DIP-switches according to the drawing below:

Where to find the DIP-switches of the remote digital controller

B

EFORE

STARTING

I do confirm having executed and checked all the above

mentioned items.

Keep for future reference.

Master

Slave 1

Slave 2

Slave 3

PCB

address

Any unit can be master, slave 1, slave 2 or slave 3.

Master

Slave 1

Slave 2

Slave 3

Remote digital

controller address

Any unit can be master, slave 1, slave 2, slave 3...

To avoid damage to the controllers liquid crystals during

winter time, do not shut off the main power supply.

1 2 3 4 5 6

OFF

1 2 3 4 5 6

OFF

1 2 3 4 5 6

OFF

1 2 3 4 5 6

OFF

1 2 3 4 5 6

OFF

1 2 3 4 5 6

OFF

1 2 3 4 5 6

OFF

1 2 3 4 5 6

OFF

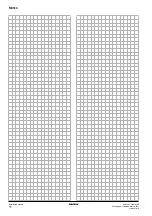

The unit should not be started, not even for a very short

period of time, before the following pre-commissioning

checklist is filled out completely.

tick

✓

when

checked

standard steps to go through before starting the unit

■

1

Check for external damage.

■

2

Open all shut-off valves indicated by a red label: "OPEN THIS

VALVE BEFORE OPERATION". (Open the liquid line, discharge

and suction (if provided) stop valves completely.)

■

3

Install main fuses, earth leak detector and main switch.

Recommended fuses: aM according to IEC standard 269-2.

Refer to the wiring diagram for size.

■

4

Supply the main voltage and check if it is within the allowable

±10% limits of the nameplate rating.

The electrical main power supply should be arranged so, that

it can be switched on or off independently of the electrical

supply to other items of the plant and equipment in general.

Refer to the wiring diagram, terminals L1, L2 and L3.

■

5

Supply water to the evaporator and verify if water flow is within

the limits as given in the table under

■

6

The piping must be completely purged.

■

7

Connect the pump contact in series with the contact of the

flowswitch, so that the unit can only come in operation when the

waterpumps are running and the water flow is sufficient.

For DICN configurations, every chiller shall have its own

flowswitch and shall be interlocked with the pump from which it

gets the flow.

■

8

Check the oil level in the compressors.

■

9

Connect the power supply to the heatertapes.

The heatertapes must be connected to an independent,

separately fused, power supply all year-round.

■

10

Install the filter kit supplied with the unit in front of the

evaporator water inlet. The filter has a mesh size of maximum

1.0 mm.

■

11

Check that all the water sensors are correctly fixed into the

heat exchanger (see also the sticker attached to the heat

exchanger).

NOTE

■

It is necessary to read the operation manual

delivered with the unit before operating the unit. It

will contribute to understand the operation of the

unit and its electronic controller.

■

Close all switch box doors after installation of the unit.

Date

Sign