Installation manual

3

EWAP400~540MBYNN

Packaged air-cooled water chillers

4PW22678-1B

U

NPACKING

AND

PLACING

THE

UNIT

1

Remove the wooden beams from the unit.

2

Install vibration mountings in case of a roofmounted unit or other

installation where noise and vibration might be an impediment.

3

Set the unit on a solid and level foundation.

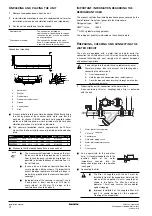

Ground level mounting

■

Fix anchor bolts into the concrete foundation. When finally fixing

the unit by means of these anchor bolts, make sure that the

washers for channel DIN434, and both field supplied rubber

plates and field supplied raw cork or rubber sheets for better

vibration protection, are installed as indicated.

■

The concrete foundation should approximately be 100 mm

higher than the floor level for ease of plumbing work and better

drain.

■

Make sure that the foundation surface is even and flat.

I

MPORTANT

INFORMATION

REGARDING

THE

REFRIGERANT

USED

This product contains fluorinated greenhouse gases covered by the

Kyoto Protocol. Do not vent gases into the atmosphere.

Refrigerant type:

R407C

GWP

(1)

value:

1652.5

(1)

GWP = global warming potential

The refrigerant quantity is indicated on the unit name plate.

P

REPARING

,

CHECKING

AND

CONNECTING

THE

WATER

CIRCUIT

The units are equipped with a water inlet and water outlet for

connection to a chilled water circuit. This circuit must be provided by

a licensed technician and must comply with all relevant European

and national regulations.

1

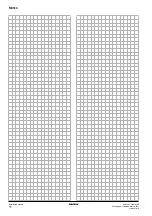

Preparing the unit for connection to the water circuit

A box containing

couplings and a filter is delivered

with the unit.

■

As a general rule for this and other

units, it is recommended to check the

insertion depth of the water

temperature sensors into the

connection pipes prior to operation

(see figure).

■

Connecting the filter

Roof mounted:

The unit must be installed on

steelchannel or I-beam frame to support

the unit on the roof, or it can be installed

on a concrete base.

Ground level mounted:

The unit must be installed on a solid

base. It is recommended to fix the unit on

a concrete base with anchor bolts.

1

Anchor bolt

2

Washer

3

Rubber plate

4

Raw cork or rubber sheet

5

Ground

6

Concrete floor

7

Ditch

Model

A

B

C

D

E

anchor bolt size

Qty

EWAP400

5906

2210

1700

1989

2125

M16x200

8

EWAP460

5906

2210

1700

1989

2125

M16x200

8

EWAP540

5906

2210

1700

1989

2125

M16x200

8

NOTE

■

The measurement tabulated is based on the fact

the base is made in the ground or on a concrete

floor. In case the base is made on a rigid floor, it is

possible to include thickness of concrete floor in

that of the base.

■

In case a base is made on concrete floor, make

sure to provide a ditch as shown. It is important to

extract drainage regardless of whether a base is

made in the ground or on the concrete floor (ditch-

sewerage).

■

Ingredient ratio of the concrete is: cement 1, sand

2 and gravel 3. Insert iron bars of Ø10 mm at

every interval of 300

mm. The edge of the

concrete base should be planed.

>200

>350

100

>100

50

X

X

>B

>A

C

>B

E

D

C

1

2

3+4

5

6

7

X-X

If air or dirt gets in the water circuit, problems may occur.

Therefore, always take into account the following when

connecting the water circuit:

1.

Use clean pipes only.

2.

Hold the pipe end downwards when removing burrs.

3.

Cover the pipe end when inserting it through a wall so that

no dust and dirt enter

1

Water inlet of the evaporator

2

coupling

3

Counter pipe

4

Field water piping circuit

5

Water inlet temperature sensor

6

Filter

7

Filter end cap

■

The filter kit supplied with the unit must be

installed in front of the evaporator water inlet by

means of the supplied

couplings as

shown in the figure. The filter has holes of

diameter 1.0 mm and secures the evaporator

against clogging.

■

Improper installation of the supplied filter will

result in severe damage of the equipment

(freezing of the evaporator).

Victaulic

®

2

3

4

6

5

1

7

2

2

Victaulic

®

≤

50 mm

Victaulic

®