D

–EIMAC00708-16EN - 56/76

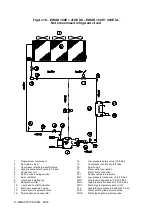

1. and 2. Suction

Main rotor flutes 'a', 'b' and 'c' are in

communication at one end with the suction

chamber via the bevelled rotor end face, and

are sealed at the other end by the star rotor

teeth. As the main rotor turns, the effective

length of the flutes increases with a

corresponding increase in the volume open to

the suction chamber: Diagram 1 clearly

shows this process. As flute 'a' assumes the

position of flutes 'b' and 'c' its volume

increases, inducing suction vapour to enter

the flute.

Upon further rotation of the main rotor , the

flutes which have been open to the suction

chamber engage with the star teeth. This

coincides with each flute being progressively

sealed by the main rotor. Once the flute

volume is closed off from the suction chamber,

the suction stage of the compression cycle is

complete.

1.

2.

3. Compression

As the main rotor turns, the volume of gas

trapped within the flute is reduced as the

length of the flute shortens and compression

occurs.

3.

4. Discharge

As the star rotor tooth approaches the end of

a flute, the pressure of the trapped vapour

reaches a maximum value occurring when the

leading edge of the flute begins to overlap the

triangular shaped discharge port.

Compression immediately ceases as the gas

is delivered into the discharge manifold. The

star rotor tooth continues to scavenge the flute

until the flute volume is reduced to zero. This

compression process is repeated for each

flute/star tooth in turn.

4.

Oil separator not shown

Figure 29

– Compression process

c

a

b

c

b

a

c

a

b

c

b

a

a

Discharge

Gas

b

a

b

Suction

Gas

b

a

c

Содержание ERAD 120E-SL

Страница 43: ...D EIMAC00708 16EN 43 76 Figure 18 Field Wiring Diagram...

Страница 75: ...D EIMAC00708 16EN 75 76...