D

–EIMAC00708-16EN - 55/76

Compressor

The single-screw compressor is of the semi-hermetic type with asynchronous three-phase two-pole engine which is

directly splined to the main shaft. The intake gas from the evaporator cools the electrical engine before entering the

intake ports. Inside the electrical engine, there are temperature sensors completely covered by the coil winding that

constantly monitor engine temperature. Should the coil winding temperature become very high (120°C), a special

external apparatus that is connected to the sensors and to the electronic controller will de -activate the corresponding

compressor.

The compressors of EW AD100E÷210E-SS/SL, ERAD120E÷250E-SS, ERAD120E÷240E-SL units are Fr3100 and the

compressors of EW AD260E÷410E-SS, EW AD250E÷400E-SL and ERAD310E÷490E-SS, ERAD300E÷460E-SL units are

F3. Fr3100 compressor has one single satellite on the upper section of the main screw; F3 compressors have two

satellites symmetrically positioned on the main screw sides.

There are only two moving rotating parts in Fr3100 compressor and three moving parts in F3 compressors and th ere are

no other parts in the compressor with an eccentric and/or alternative movement.

The basic components are therefore only the main rotor and the satellites that carry out the compression process,

meshing perfectly together.

Compression sealing is done thanks to a suitably shaped special composite material that is interposed between the main

screw and the satellite. The main shaft on which the main rotor is splined is supported by 2 ball bearings. The system

made up in this way is both statically and dynamically balanced before assembly.

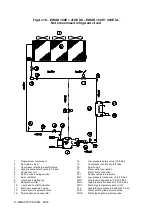

Figure 27 - Picture of Fr3100 compressor

Figure 28 - Picture of F3 compressor

On the upper part of Fr3100 compressor, there is a large access cover allowing quick and easy maintenance; on F 3

compressor, the access to the internal parts is allowed by two covers positioned sidewise.

Compression process

With the single-screw compressor the intake, compression and discharge process takes place in a continuous manner

thanks to the satellite. In this process the intake gas penetrates into the profile between the rotor, the teeth of the satel lite

and the compressor body. The volume is gradually reduced by compression of the refrigerant. The compressed gas

under high pressure is thus discharged in the built-in oil separator. In the oil separator the gas/ oil mixture and the oil are

collected in a cavity in the lower part of the compressor, where they are injected into the compression mechanisms in

order to ensure the compression’s sealing and lubrification of the ball bearings.

Содержание ERAD 120E-SL

Страница 43: ...D EIMAC00708 16EN 43 76 Figure 18 Field Wiring Diagram...

Страница 75: ...D EIMAC00708 16EN 75 76...