7 Service and maintenance

Installation and operating manual

23

EKHW(D/C/P)(300/500)(P)B

Daikin Altherma ST (Hot water storage tank)

008.1633099_00 – 06/2020

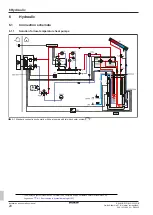

Short name

Meaning

HYW

Hydraulic shunt

MAG

Diaphragm expansion vessel

P

High-efficiency pump

P

1

Central heating pump

P

HP

Heating circulation pump

P

K

Boiler circuit pump

P

MI

Mixing circuit pump

P

S

Solar operating pump

+

P

Z

Circulation pump

PWT

Plate heat exchanger (condenser)

RLB

Return temperature limiter

RoCon BF

Boiler controller

RT

Room thermostat

S#B

Hot water storage tank EKHWP500Bx

S#I

Hot water storage tank EKHWCB500Bx

S#K

Hot water storage tank EKHWCH500PBx

S#L

Hot water storage tank EKHWCB500PBx

S#P

Hot water storage tank EKHWDB500Bx

SOL-M1

Solar communication module SOL-PAC LT/HT

SK

Solar panel field

SV

Safety overpressure valve

T

AU

Outside temperature sensor

T

DHW

Storage tank temperature sensor (heat generator)

T

K

Solar collector temperature sensor

T

MI

Mixer circuit flow temperature sensor

T

R

Solar return flow temperature sensor

T

RH

Return flow temperature sensor heating circuit

T

S

Solar storage tank temperature sensor

T

V

Solar flow temperature sensor

V

Fan (vaporiser)

VS

Protection against scalding VTA32

7

Service and maintenance

The hot water storage tank is practically maintenance free as a

result of its design. No corrosion protection equipment is required

(such as sacrificial anodes). This means there is no need for

maintenance work such as changing the protective anodes or

cleaning the inside of the storage tank.

Regular inspection of the domestic hot water storage tank

guarantees a long working life and fault-free operation.

DANGER: RISK OF ELECTROCUTION

Live parts can cause an electric shock on contact and

cause fatal burns or injuries.

▪ If there is an electric immersion heater or control and

pump unit installed in the hot water storage tank then

these components must be isolated from the power

supply before starting the work (e.g. fuse, main switch

switched off and secured against inadvertent switching

on again).

DANGER: RISK OF ELECTROCUTION

All work performed on live components must be carried out

in accordance with the proper procedures, otherwise there

may be a danger to the life and health of individuals and

the function may be impaired.

▪ Repair of damage to current-carrying components only

by heating specialists authorised and recognised by the

energy supply company.

7.1

Periodic checks

The filling water can evaporate slightly over a period of time as a

result of the design. This process does not represent a technical

fault, but is rather a physical property which requires periodic

checking and correction of the water level by the operator if

necessary.

▪ Visual check of the water storage tank level (filling level indicator)

▪ Refill water if necessary (see

15]) and also

determine the cause of the low water level and rectify it.

7.2

Annual inspection

▪ Carry out a functional inspection of the electric immersion heater

by checking the temperature display and the switching states in

the individual modes: see the associated installation and operating

instructions.

▪ If a solar system is connected and is in operation, switch it off.

▪ Visual inspection of the general condition of the domestic hot

water storage tank.

▪ Visual check of the water storage tank level (filling level indicator)

▪ If a drain-back solar system

is installed, wait until solar

panels are drained completely.

▪ Refill the water if necessary (see

15]) and

also determine the cause of the low water level and rectify it.

▪ Check the connection of the safety overflow and drain hose for

leaks, free drainage and gradient.

▪ If necessary, clean the safety overflow and drain hose and

reinstall it; replace damaged parts.

▪ Visual check of connections and pipes. In the event of damage,

determine the cause.

▪ Replace defective parts.

▪ Check all electrical components, connections, and cables.

▪ Repair damaged parts or replace them.

▪ Check the water pressure of the cold water supply (<10 bar)

▪ and if necessary the fitting or adjustment of the pressure

reducer.

▪ Clean the plastic storage tank

with soft cloths

and a mild

cleaning agent

. Do not use cleaning agents containing

aggressive solvents, as this will damage the plastic surface.

Содержание EKHWCH300B

Страница 33: ......

Страница 34: ......

Страница 35: ......

Страница 36: ...008 1633099_00 06 2020 Copyright Daikin Verantwortung f r Energie und Umwelt...