EKHBH/X008BB

Indoor unit for air to water heat pump system

4PW62570-1A – 01.2011

Installation manual

46

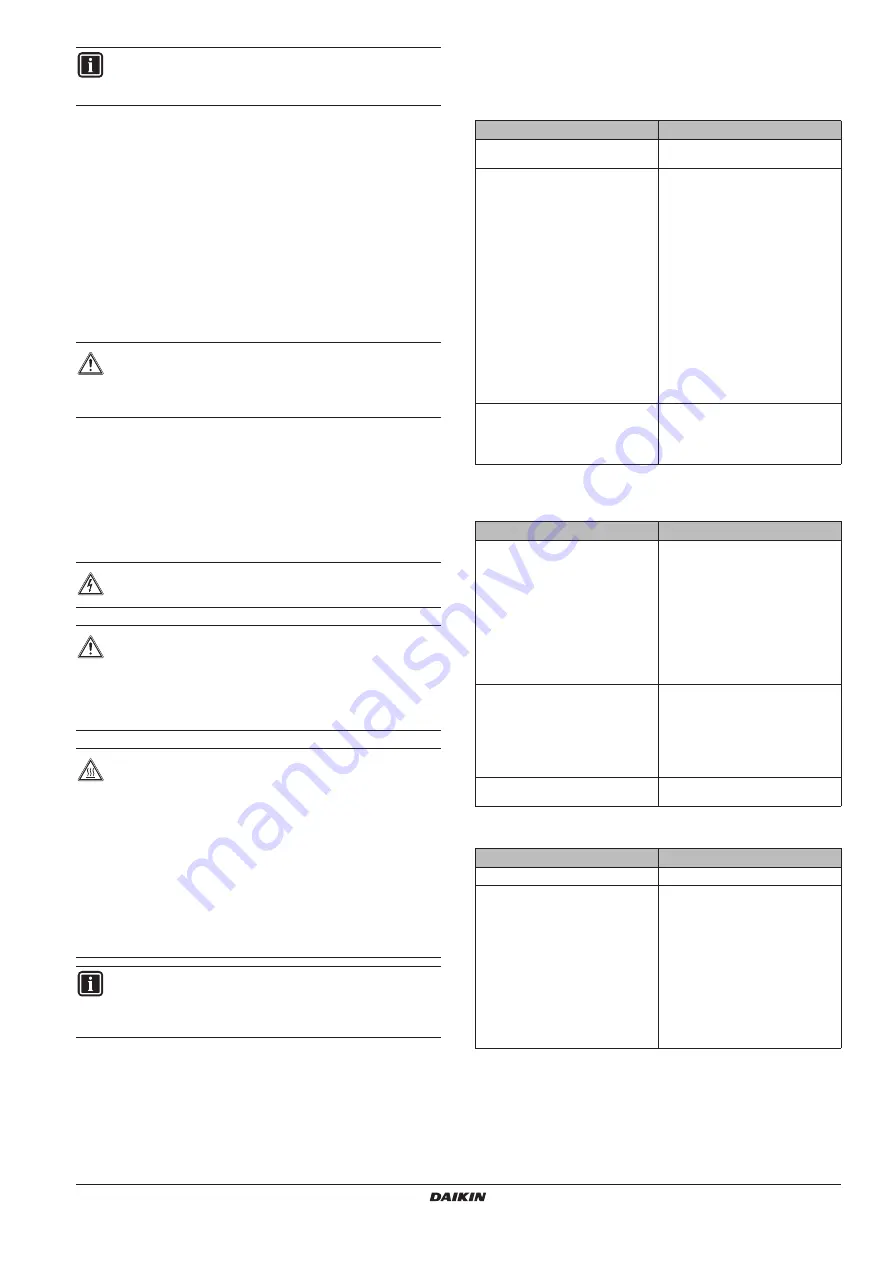

11. T

ROUBLESHOOTING

This section provides useful information for diagnosing and

correcting certain troubles which may occur in the unit.

This troubleshooting and related corrective actions may only be

carried out by your installer.

11.1. General guidelines

Before starting the troubleshooting procedure, carry out a thorough

visual inspection of the unit and look for obvious defects such as

loose connections or defective wiring.

When a safety device was activated, stop the unit and find out why

the safety device was activated before resetting it. Under no

circumstances safety devices may be bridged or changed to a value

other than the factory setting. If the cause of the problem cannot be

found, call your local dealer

.

If the pressure relief valve is not working correctly and is to be

replaced, always reconnect the flexible hose attached to the pressure

relief valve, to avoid water dripping out of the unit!

11.2. General symptoms

Symptom 1: The unit is turned on (

y

LED is lit) but the unit is

not heating or cooling as expected

Symptom 2: The unit is turned on but the compressor is not

starting (space heating or domestic water heating)

Symptom 3: Pump is making noise (cavitation)

INFORMATION

Refer to the service manual to carry out any service mode

operation.

DANGER

When carrying out an inspection on the switch box of the

unit, always make sure that the main switch of the unit is

switched off.

DANGER: ELECTRIC SHOCK

See

"2. General safety precautions" on page 2

WARNING

In order to avoid a hazard due to inadvertent resetting of

the thermal cut-out, this appliance must not be supplied

through an external switching device, such as a timer, or

connected to a circuit that is regularly switched on and off

by the utility.

DANGER: DO NOT TOUCH PIPING AND INTERNAL

PARTS

■

Do not touch water pipes during and immediately after

operation as the pipes may be hot.

■

Do not touch the refrigerant pipes during and

immediately after operation as the refrigerant pipes

may be hot or cold, depending on the condition of the

refrigerant flowing through the refrigerant piping,

compressor, and other refrigerant cycle parts.

■

Do not touch the internal parts (pump, backup heater,

etc.) during and immediately after operation.

See

"2. General safety precautions" on page 2

INFORMATION

For problems related to the optional solar kit for domestic

water heating, refer to the troubleshooting in the

installation manual of that kit.

P

OSSIBLE

CAUSES

C

ORRECTIVE

ACTION

The temperature setting is not

correct.

Check the controller set point.

The water flow is too low.

• Check that all shut-off valves of

the water circuit are completely

open.

• Check if the water filter needs

cleaning.

• Make sure there is no air in the

system (purge air).

• Check on the manometer that

there is sufficient water pressure.

The water pressure must be

>1 bar (water is cold)

• Check that the pump speed

setting is on the highest speed.

• Make sure that the expansion

vessel is not broken.

• Check that the resistance in the

water circuit is not too high for the

pump (refer to

The water volume in the installation

is too low.

Make sure that the water volume in

the installation is above the minimum

required value (refer to

the water volume and expansion

vessel pre-pressure" on page 16

).

P

OSSIBLE

CAUSES

C

ORRECTIVE

ACTION

The unit must start up out of its

operation range (the water

temperature is too low).

In case of low water temperature, the

system utilizes the backup heater to

reach the minimum water

temperature first (15°C).

• Check that the backup heater

power supply is correct.

• Check that the backup heater

thermal fuse is closed.

• Check that the backup heater

thermal protector is not activated.

• Check that the backup heater

contactors are not broken.

The benefit kWh rate power supply

settings and electrical connections

do not match.

If [d-01]=1 or 2, the wiring requires

specific installation like illustrated in

"Connection to a benefit kWh rate

power supply" on page 22

. Other

correctly installed configurations are

possible, but are to be specific for

the type of benefit kWh rate power

supply type at this specific site.

The benefit kWh rate signal was sent

by the electricity company.

Wait for the power to return.

P

OSSIBLE

CAUSES

C

ORRECTIVE

ACTION

There is air in the system.

Purge air.

Water pressure at pump inlet is too

low.

• Check on the manometer that

there is sufficient water pressure.

The water pressure must be

>1 bar (water is cold).

• Check that the manometer is not

broken.

• Check that the expansion vessel is

not broken.

• Check that the setting of the pre-

pressure of the expansion vessel

is correct (refer to

Содержание EKHBH008BB Series

Страница 62: ......

Страница 63: ......

Страница 64: ...4PW62570 1A 01 2011 Copyright 2010 Daikin...