21

WARNING:

When servicing, use only original equipment replacement parts. The use of any

other parts may create a safety hazard or cause damage to the circular saw.

Always order by PART NUMBER, not by key number.

Key #

Part #

Part Name

Quantity

1

4050050001

Hexagon flange bolt M6*13

1

2

2010140009

Outer flange

1

3

6070020001

Saw blade

1

4

2030110005

Circlip for shaft

1

5

3160040011

Moveable guard

1

6

2050050004

Torsional spring

1

7

4020010001

Screw M4*8

1

8

4040010009

Flat washer

1

9

3140090004

Guard stop

1

10

4030010106

Screw ST3.9*19

4

11

2020080033

Left fixed guard

1

12

2020080034

Right fixed guard

1

13

4020010028

Screw M3*8

4

14

2040140009

Pin screw

1

15

4040010011

Flat washer 5

1

16

4040030003

Spring washer

Φ

5

1

17

4060010008

Hex nut M5

1

18

3010070017

Left housing

1

19

3120040043

Lock-out lever

1

20

2050060014

Spring

1

!

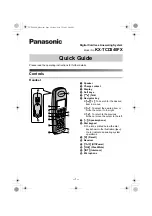

PARTS LIST

Содержание ConstruX

Страница 20: ...20 EXPLODED VIEW...

Страница 23: ......