Service Manual Ponygraphic

Chapter 3

Part Description

3.7

3.5.4. Assembly

Drawing

3.5.5. Warnings & Indications in Event of Failure.

•

Printing Failure

•

Paper jam during Printing

•

No Printout

3.6. Opto

Electronic

Assembly(C00095-01-05)

3.6.1. Function

The flow meter is composed by a Bi-directional turbine and an Optoelectronic transducer.

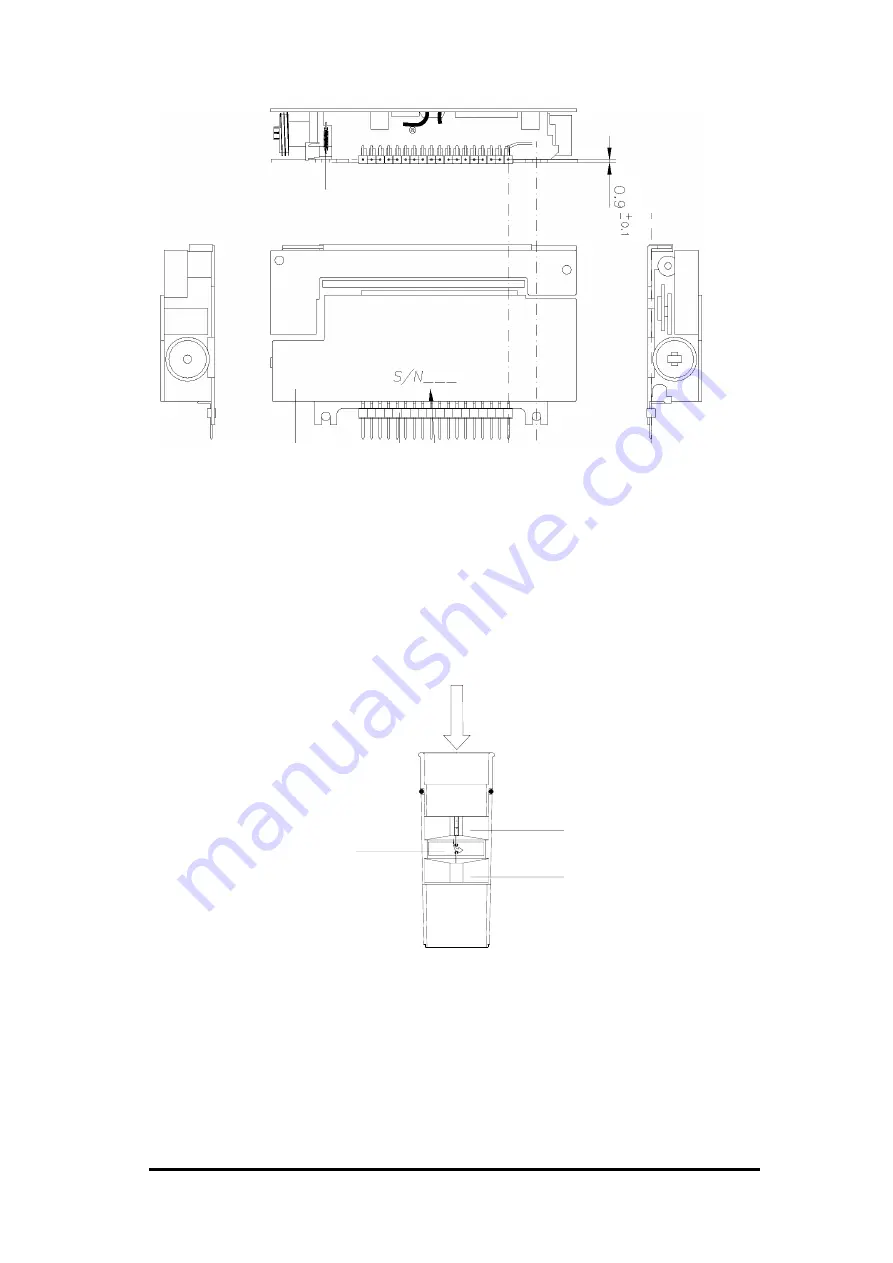

The Turbine is made of (see figure) a transparent tube with two helical conveyors to which is

fixed (rotating free) a very lightweight rotor (blade).

Expired Flow

Conveyor

Conveyor

Rotor

(blade)

3.6.2. Description

The Optoelectronic transducer contains 2 couples of Infrared Emitter/Receiver diodes to detect

the position of the rotor. The air passing through the helical conveyors, takes a spiral motion

which causes the rotation of the turbine rotor. The rolling blade interrupts the infrared light

beamed by the diodes of the optoelectronic reader, each interruption represents half turn of the

rotor, this is used to measure the number of turn in the time. There is a constant ratio due to

software linearization between air passing through the turbine and number of turns. This allows

for an accurate measurement of volume and flows. Refeto the electrical diagram and layout of

the output signals from the infrared receivers D4 (Rx1) and D3 (Rx2) as shown following figure.