Cool-Air Doors

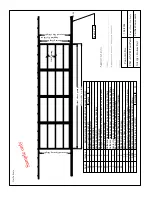

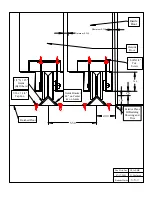

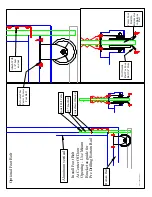

CSA-5-BR Bottom Rolling Slide Door

Assembly and Installation Instructions

1.

Open all structural component and hardware boxes

and compare with

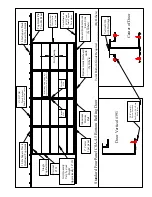

itemized list in this instruction. Note: Structural components and hardware may

arrive in separate shipments.

2.

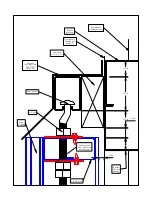

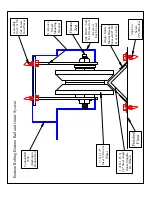

Install Top Guide

track per print. Use mounting brackets spaced per print. The

16 gauge box track top guide must be drilled for a 3/8” bolt at each mount

bracket. Depending on the print for the job this will be either 24” or 48” on center.

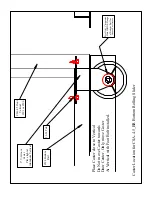

3.

Install

1-1/4” X 1-1/4” X 1/8” structural steel angle (supplied by others)

bottom

guide

per print. Use supplied mount clips with two TapCon screws per clip four

foot on center and at each joint. Recommended to tack weld bracket to bottom

guide in slotted hole. One TapCon per bracket authorized if tack welded except at

joints. Recommend cutting exposed end of bottom guide at 45 Degree angle to

reduce sharp cutting edge.

4.

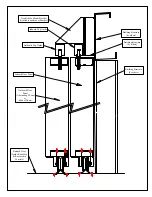

Measure

distance between

bottom of top track

and

top of bottom guide

.

5.

Allowing ¾” between top of door and bottom of top track and 3-1/2” for bottom

rail / bottom roller / bottom guide track,

trim vertical

to the measurement in step

4 minus 4-1/4”. Adjust if more or less space is needed between door and top track

or if different sized bottom guide is used.

6.

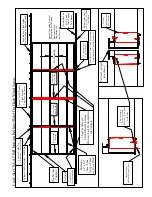

Lay out Door

structural components per component layout. Suggested to start

face down with protection to not scratch the paint.

7.

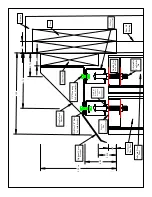

Install Top Rail Girt and Aluminum Bottom

Rail with one screw at each joint.

Check door print to determine quantity of top rail girts and determine if a bottom

rail reinforcing girt is supplied.

8.

Locate and place remaining girts

per the girt spacing. Numbers are starting

from top down. This may vary from the number specified if the verticals are

trimmed at site.

9.

Internal reinforcements

for the verticals are optional and may be supplied for

one or more vertical. If this vertical reinforcement girt section is supplied, install

the top girt for each panel, then install the reinforcing girt into the vertical, Tek

through the vertical near the top and near the bottom of the reinforcing member

and then butt the next horizontal girt tightly against the vertical reinforcing girt.

Continue this sequence all the way down. In some applications, a vertical

reinforcing girt will be supplied for only one side of the panel and not the other.

10.

Square the door panel

by measuring from corner to corner diagonally and

equalizing.

11.

Lay out optional

Walk Door Framed

opening (if supplied) per print. Install tek

screws in girt installed as door jamb inside vertical only on rear side (away from

“J” trim)

12.

Fasten

two tek screws at each joint on the rear of door