Unidrive Regen Installation Guide

29

Issue Number: 2

www.controltechniques.com

9.3

Regen drive commissioning

•

Ensure power and control connections are made as specified in this Installation Guide.

•

Ensure the Regen and motoring drives are not enabled.

•

Switch on the AC supply.

•

Both the Regen and motoring drives should now power up through the start-up circuit in standard open loop mode.

•

On the Regen drive, configure the drive type Pr 11.31 (Pr 0.48) to REGEN and set the additional parameters up for the auxiliary contactor (refer

to Chapter 4 Control circuit connections on page 8).

•

The Auxiliary and Main contactors should now close; the start-up circuit is disabled at this point.

•

On the Regen drive, set up the switching frequency and DC bus set point voltage to the required values in either Menu 0 or Menu 15, refer to

Chapter 8 Parameter descriptions on page 22. Save the parameters.

•

The Regen drive can now be enabled, the Regen drive should display ACT.

•

The commissioning of the motoring drive(s) can now be carried out.

9.4

Motoring drive commissioning

The setting of certain parameters in the motoring drive must be given special consideration when used in a Regen system.

Ramp Mode - Pr 2.04 (Pr 0.15)

When a motoring drive is used in a Regen system, the ramp mode should be set to FAST. The default setting of standard control will result in incorrect

operation.

Voltage Control Mode - Open loop only Pr 5.14 (Pr 0.07)

The default setting of UR_I does not function correctly in the motoring drive when used in a Regen system. When the system is powered up, the

motoring drive is disabled while the Regen synchronises to the AC supply. The resultant delay before the motoring drive is enabled means that the

stator resistance test cannot be completed. When open loop vector operation is required the voltage mode should be set to UR_S.

Drive Enable Function - Open loop only Pr 8.07

The default setting for terminal 30 in the open loop motoring drive is an external trip (Et) function. When the Regen drive has synchronised to the AC

supply and the enable signal is applied to the open loop drive, a drive reset is required to clear the external trip. If a reset signal is not available or

desirable, then Pr 8.09 should be set to a 1. Terminal 30 then acts as a non latching input with the drive displaying INH when disabled.

AC Supply Loss Mode - Pr 6.03

The motoring drive will not operate correctly if the AC supply loss mode is set to STOP. If the AC supply is lost, the Regen drive disables the motoring

drive and prevents a controlled stop from being completed.

Auto Start - Pr 6.02

The Auto Start function will not operate correctly when used in a Regen system due to the delay in applying the enable signal to the motoring drive as

described above in Voltage Control Mode. The delay means that the run latch has already cleared when the enable signal is applied.

9.5

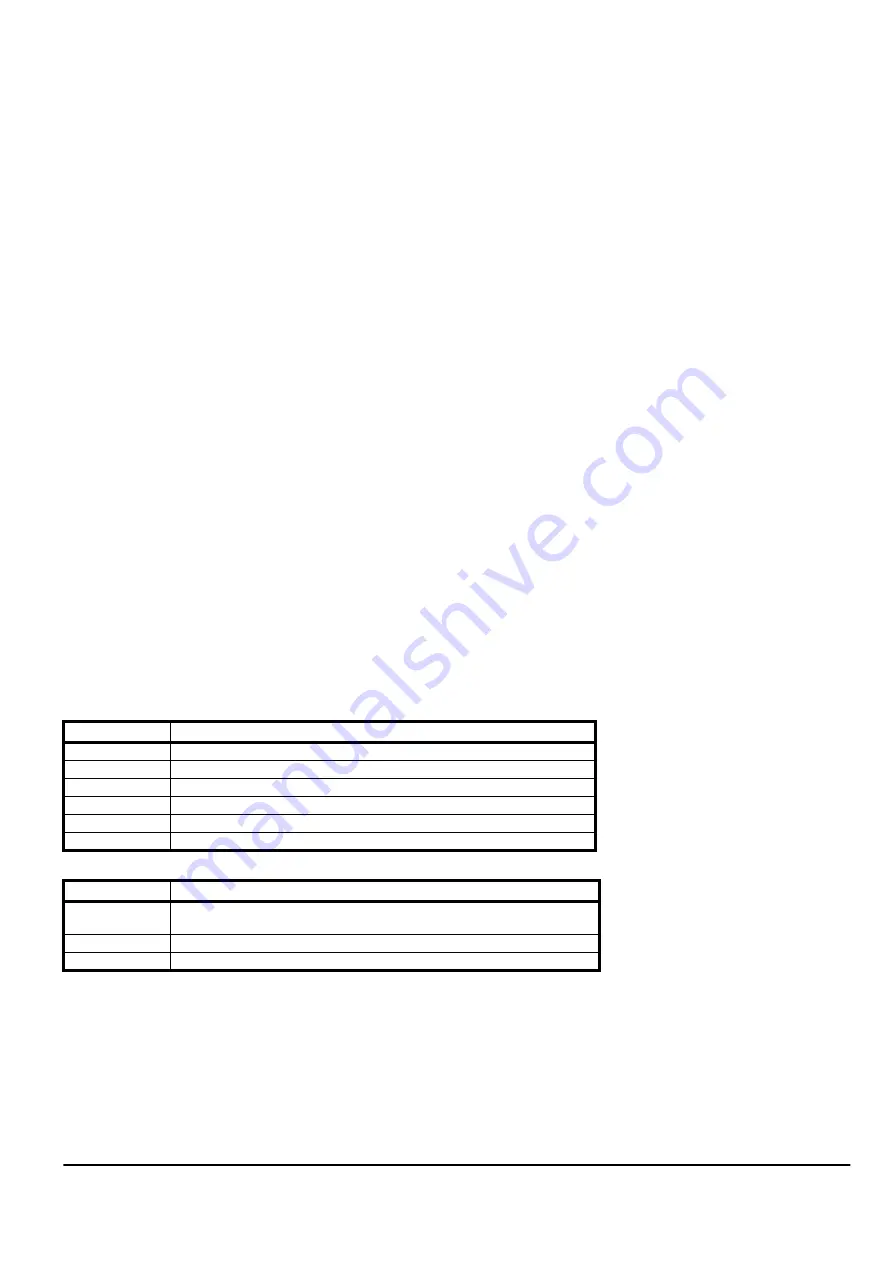

Trip codes

Below are the trip codes which are specific to Unidrive in Regen mode. These are in addition to the trips listed in the Unidrive size 1 to 5 User Guide.

Table 9-2

Trip codes

Table 9-3

Status display

Trip Code

Description

LI.SYNC

Regen sinusoidal rectifier failed to synchronise to line voltage

Ph Det

Failed to correctly detect the phasing of the supply

Fr Lo

Line frequency to low

Fr Hi

Line frequency to high

PLL OI

Overcurrent during final synchronisation of PLL to supply

PLL Ph

Phasing error during final synchronisation of PLL to supply

Status Display

Description

STOP

Drive Enabled but AC voltage too low, or DC bus voltage still rising, or DC bus

voltage still falling. Waiting for correct conditions to synchronise onto line

SCAN

Drive enabled and synchronising to line

ACT

Drive enabled, synchronised and active