Installing the DeviceMaster 500 and the SICK LMS Scanner (Windows):

2000472 Rev. C

7

Connecting the Power and Verifying Installation

Connecting the

Power and Verifying

Installation

Use the following procedure to wire the power terminal connector and connect the

DeviceMaster 500 to a power source.

1.

Connect the screw terminal power connector to the wires on the power supply

as displayed. The power supply must conform to the specifications for the

DeviceMaster 500 embedded.

Observe proper ESD techniques when connecting and disconnecting

the DeviceMaster 500.

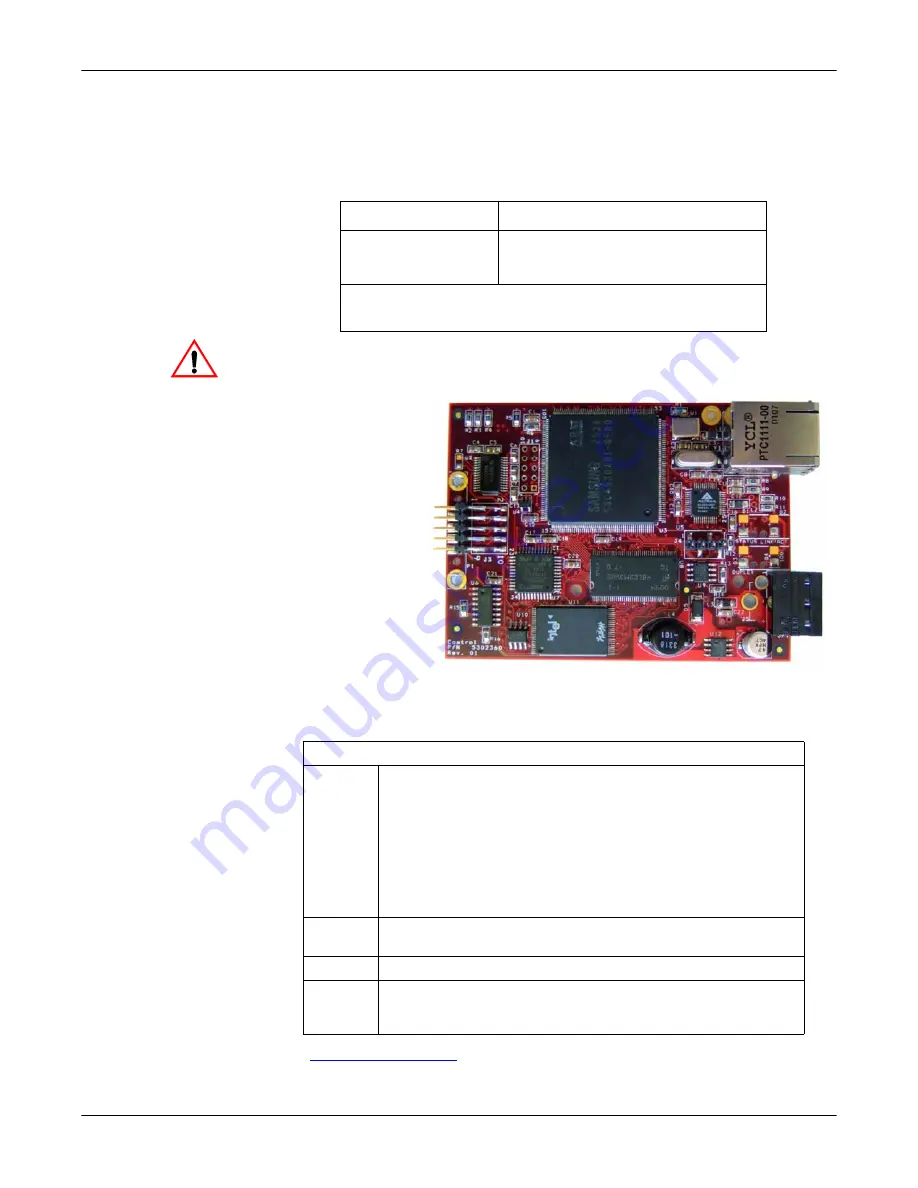

2.

Use a small flat head screw to lock the wires into place.

3.

Plug the screw

terminal power

connector into

JP1

on the

DeviceMaster

500 by aligning

the scalloped

sides.

4.

Apply power to

the DeviceMaster

500.

5.

Verify the

Status

LED has

completed the

boot cycle and

network

connection for the

DeviceMaster

500 is functioning properly using the table below.

The LEDs are located between the RJ45 connector and the power terminal

block.

Go to

on Page 9 to complete the installation.

Power Supply†

Specifications

Output voltage

Current

Power

5-30VDC

100 mA (Min.) @ 24VDC

2.5 W

†

Any power supply that meets current consumption, voltage,

power, and connector pinouts requirements can be used.

Caution

LED Descriptions

Status

When lit, the

Status

LED (

D1

) on the DeviceMaster 500

indicates the devices is fully powered and has completed the

boot cycle.

Note:

The

Status

LED flashes for approximately 15 seconds

while booting. When the bootloader completes the

cycle, the LED has a solid, steady light.

When the

Bootloader completes the cycle, the LED has a solid,

steady light that blinks approximately every 30

seconds.

Link/Act

When lit, the

Link/Act

LED (

D2

) indicates a working

Ethernet connection.

Duplex

When lit, the

Duplex

(

D3

) LED indicates full-duplex activity.

100

When lit, the

100

(

D4

) LED indicates a working 100 MB

Ethernet connection (100 MB network, only). If the LED is

not lit, it indicates a 10 MB Ethernet connection.

LEDs

JP1