SECTION - 5

MAINTENANCE &TROUBLESHOOTING

5-1 ROUTINE MAINTENANCE

WARNING

SEE SAFETY SIGNAL AT THE BEGINING THIS M ANUAL

TIME

Above normal equipment use: Check all labels ( see 6 month entry ), repair any damaged

insulation or replace holder or work cable, clean internal parts ( see 6 month entry ), clean and

tighten connections at holder cable and work clamp.

Every month

Every 3 months

Every 6 months

MAINTENANCE

Replace Unreadable Labels, Tape Or Replace Cracket Cables, Clean And Tighten W eld

Terminals, Replace Cracket Parts.

Blow Out Or Vacuum inside,During Heavy Service Clean Monthly.

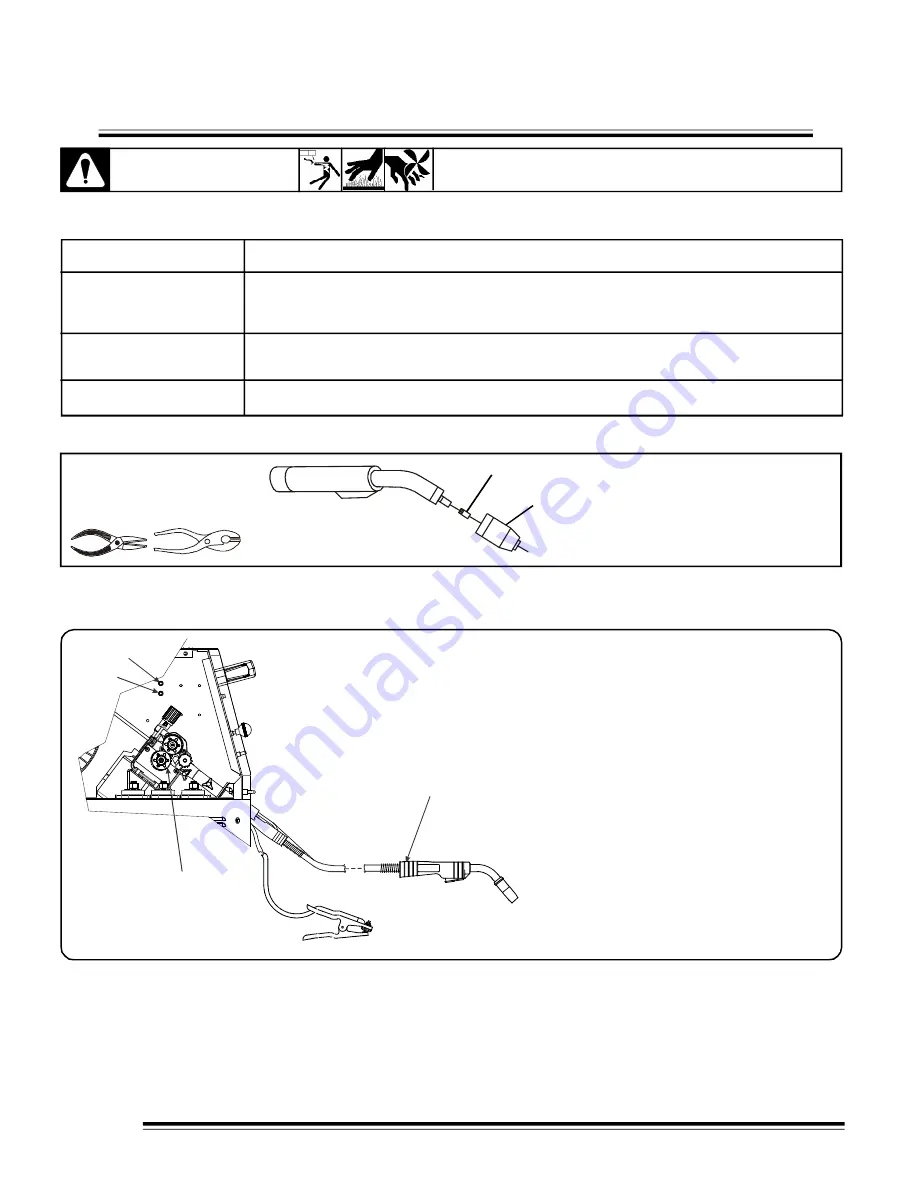

FIGURE 5-1. CHANGING CONTACT TIP.

Turn off and disconnect the unit.

1.- NOZZLE.

2.- CONTACT TIP.

Cut wire remaining

of the contact tip, remove Nozzle, remove

the contact tip and install one new.

Reinstall nozzle.

Tools Needed

2

1

5-2 CHANGING CONTACT TIP.

5-3 CIRCUIT BREAKERS CB1 AND CB2

1 Circuit Breaker CB2

CB2 protects Remote 14 receptacle ( RC3)

from overload.

2 Circuit Breaker CB1

If CB1 opens, wire feeding stops.

3 Welding Gun (Not Included)

Check gun liner for blockage or kinks.

4 Wire Drive Assembly

Check for jammed wire, binding drive gear

or misaligned drive rolls.

Allow cooling period and reset breaker.

Close the door

5-4 UNIT OVERLOAD

If unit is used beyond capacity (excessive wire feed, shorted output, etc.), wire feeds but is not energized.

Release gun trigger to reset this condition.

10

3

1

2

4

Содержание DELTA MIG 300

Страница 20: ...FIGURE 7 1 MAIN ASSEMBLY 11 12 3 4 17 2 16 6 10 14 1 5 9 7 8 13 15 18 19 20 20 20 ...

Страница 25: ...NOTES ...