PM1323

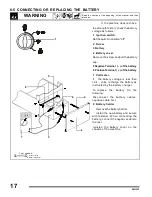

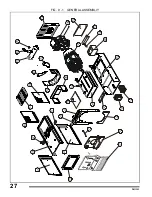

6-6 ADJUSTMENT ENGINE SPEED

Engine speed have been factory set and

not should require adjustment. After tuning engine

check engine speed with a tachometer.See table

for proper no load speeds. If is necesary, adjustment

speed as f ollow:

Starts engine and turn fine control adjust

amperes/volts at 10.

IDLE

SPEED

SETING

Set the switch speed control at run/ idle

pos ition.

/

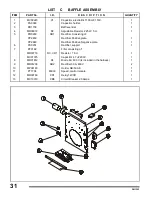

1.- Adjust screw of solenoid valve.

2.- Support solenoid valve.

3.- Solenoid valve.

4.- Screw for seting solenoid valve Lose the screws

for adjusting the speed.

5.- Gobernor arm.

Pull the gobernor arm to the solenoid valve and

adjust the following.

Slide the solenoid valve to front for increasing

the speed or to back for decreasing the speed,

up to adjust the engine speed to 2200 rpm and

tight the screw (4)

6.- Carburator.

7.- Carburator top.

8.- Adjust sc rew.

W ith the selenoid valve energized, adjust the

screw up to the screw touch with the carburator

top.

Adjustment engine speed.

Set at the panel machine the switch speed control

at high speed position

9.- Arm aceleration

10.-Speed adjustment nut

Turn the adjusting nut clockwise to increase the

speed or c ounterclockwise to lower it..

WARNING

TOOLS NEEDED

1/4", 3/8" in

6.3 mm, 9.5 mm

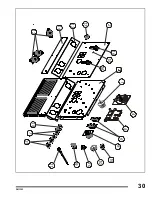

SUPERIOR VIEW

( WITHOUT AIR FILTER)

READ SAFETY BLOCKS at beginning of manual before proceeding.

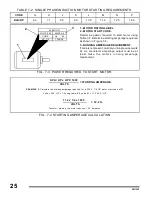

220 0+/- 100r pm

37 00 +/ -5 0r pm

H z

37+/-1.5

61.5+/-1

18

Содержание BRONCO 255K XD

Страница 35: ...PM1323 6 7 21 8 17 15 16 14 18 12 1 2 3 3 3 4 5 19 20 10 9 11 16 13 30...

Страница 38: ...NOTES...