TS415

Rev N/C

03/01/12

HK

Comco ESD Control ProCenter Plus

TM

CTR201-1 & CTR201-2

The ESD Control model of the Comco ProCenter Plus employs features that help reduce the dangers of electro-static

charge build-up, sparking, and damage to the work pieces.

HOW IT WORKS:

The ESD Control ProCenter Plus is equipped with an ionizer bar with a series of electrode probes that continuously emits

a flow of charged ions into an air stream flowing out from around each of the probes. This flow of highly ionized air floods

the ProCenter’s work area and quickly neutralizes any surface charges.

To further reduce the build up of electro-static charges the ProCenter Plus includes the following accessories for

grounding the nozzle and work piece:

Edge-Connector Grounding Bar

The board edge-connector grounding bar (WS2023) should be used to ground all edge pins on boards that have edge

connectors. This device is made of a conductive rubber material and is connected through a 1-megohm resistor to a

banana plug, which is to be plugged into one of the grounding receptacles in the ProCenter’s Floor. It is recommended

that as many connectors as possible on the target board be grounded.

Needle Probe

The needle probe (WS2021) is used to pierce through the conformal coating to ground a target trace when the defect is

known to be an open trace with no conductive path to ground. The abrasive blast can quickly charge an open section of

trace to voltages high enough to break down the insulation and spark to other traces, or across the defect. The spark

currents can be very high and cause damage. The ionized air can neutralize the field by depositing a lot of charge on the

outside of the coating, but this still leaves a dangerously charged trace. The needle probe provides a solution in the

special case when repairing a batch of boards with this type of known defect.

The needle probe also must be plugged

into one of the grounding receptacles in the ProCenter’s floor with its banana plug.

Grounded Handpiece & Conductive Nozzles

Always use the grounded handpiece assembly (WS2030-3) with a conductive nozzle installed. Some abrasives can build

up an electrical static charge in the handpiece. Proper grounding of the nozzle and handpiece will reduce the charge on

the abrasives and prevent an electro-static charge from being built up in the nozzle and operator, and arcing to the target

work area. Whenever replacing the nozzle, always replace with a conductive nozzle. See the chart below for nozzle

selection. The handpiece hose is connected to a bulkhead connector in the right side of the cabinet. The handpiece’s

ground wire has a banana plug which must be plugged into one of the grounding receptacles in the ProCenter’s floor

under the bulkhead connector.

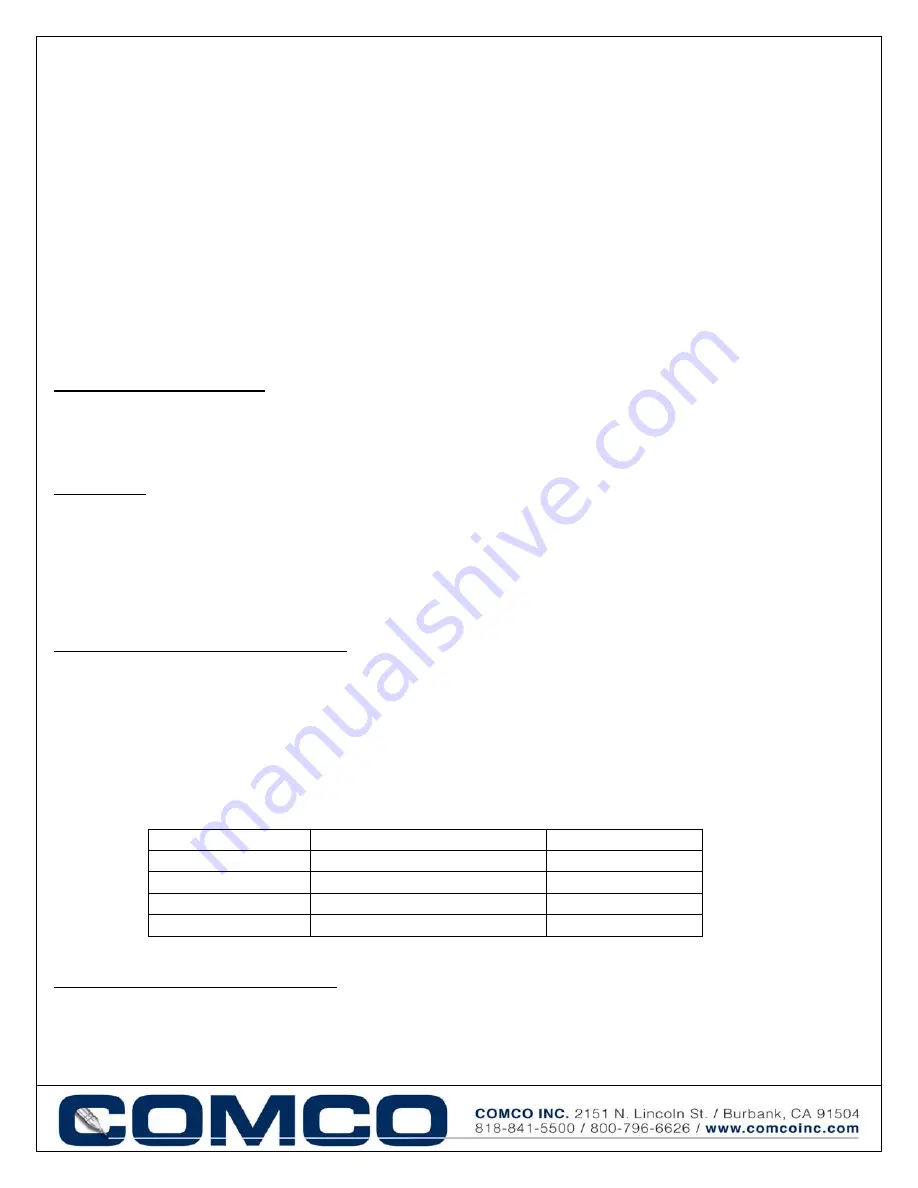

High Performance Conductive Nozzle Selection Chart

Part Number

Nozzle Orifice Size (ID)

Color

MB1520-18C .018" Violet

MB1520-30C .030" Green

MB1520-29C .046" Yellow

MB1520-39C .060" Red

Grounding Jacks for Operator Wrist Straps

The grounding receptacles in the ProCenter's floor can also be used for wrist straps. If you are using Wrist Straps (not

included) they can also be plugged into one of the grounding receptacles located outside of the blast cabinet in either side

of the frame.