4. DISASSEMBLING AND SERVICING

55

Standard

Service Limit

0.015-0.050mm

0.12mm

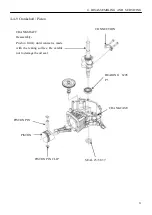

d)

Piston ring side clearance

Check with placing each ring into each-self groove. The piston

ring should be freely turned without loosening and sticking.

Then measure with inserting feeler into clearance of the ring and

upper and lower face.

Standard

Service Limit

0.030-0.065mm

0.15mm

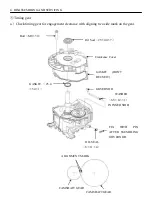

e)

Piston ring end gap

Flatly place the piston into the cylinder with pushing the

piston head to working position.

Measure the opening clearance with feeler, that clearance

not too big or not to small, too big can result in cylinder

sealing performance poor while too small can result in

piston expanded from heating and blocked in the cylinder,

PISTON RING

thus causing piston broken and “sticking”. If opening clearance is too small, file the opening

with fine flat file. Often check in the cylinder when filing until the proper clearance is got.

Standard

Service Limit

0.2-0.4mm

1.0mm

④

Check connecting rod

If connecting rod bending, twisting or big end shaft bush and small end outer ring movement

or crack on one side, should be rejected and replaced with new one.

a)

Check small end diameter

If out of the standard or exceed service limit, replace the connecting rod.

Содержание Y173V

Страница 4: ......

Страница 8: ...2 DIMENSION AND TORQUE 4 2 DIMENSION AND TORQUE 2 1 Dimension ...

Страница 9: ...5 2 DIMENSION AND TORQUE 2 2 The Position Of Installing Hole 2 3 PTO Installing Drawing Q161 Shaft ...

Страница 31: ...29 4 DISASSEMBLING AND SERVICING Don t place the flammable materials near the exhaust vent during operation ...

Страница 48: ...46 4 DISASSEMBLING AND SERVICING INTAKE VALVE Reassembly ...

Страница 52: ...50 4 DISASSEMBLING AND SERVICING check operation If the valve does not operate smoothly CORRECT INCORRECT ...

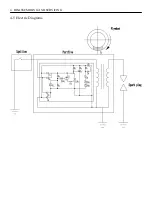

Страница 64: ...4 DISASSEMBLING AND SERVICING 4 5 Electric Diagrams ...

Страница 65: ...61 appendix TRANSFORMATION POINTS Engine Cover SHROUD Recoil Starter ...

Страница 66: ......