Chapter 3 — Waterside Care and Requirements

3-8

Part No. 750-184

Objectives of water treatment in general are:

1. Prevent hard scale deposits or soft sludge deposits, which reduce

heat transfer and can lead to overheated metal and costly

downtime and repairs.

2. Eliminate corrosive gases in the supply or boiler water.

3. Prevent intercrystalline cracking or caustic embrittlement of

boiler metal.

4. Prevent carryover and foaming.

Accomplishment of the above objectives generally requires proper

feedwater treatment before and after introduction of the water into

the boiler. The selection of pre-treatment processes depends upon

the water source, its chemical characteristics, amount of makeup

water needed, plant operating practices, etc. Treating methods

include filtering, softening, de-mineralizing, deaerating, and

preheating. After-treatment involves chemical treatment of the

boiler water.

Because of the variables involved, no single boiler compound can

be considered a “cure-all” nor is it advisable to experiment with

homemade treating methods. Sound recommendations and their

employment should be augmented by a periodic analysis of the

feedwater, boiler water, and condensate.

The internal or waterside surfaces of the pressure vessel should be

inspected with enough frequency to determine the presence of any

contamination, accumulations of foreign matter, or corrosion, and/

or pitting. If any of the conditions are detected, contact your local

Cleaver-Brooks authorized representative for advice on corrective

action.

A properly sized water meter should be installed in the raw water

make-up line in order to accurately determine the amount of raw

water admitted to the boiler (steam or hot water) and to aid in

maintaining proper waterside conditions.

D. CLEANING

1. HOT WATER AND STEAM PIPING

Steam and water piping systems connected to the boiler may

contain oil, grease, or foreign matter. The impurities must be

removed in order to prevent damage to pressure vessel heating

surfaces. On a steam system, the condensate should be wasted

until tests show the elimination of undesirable impurities. During

the period that condensate is wasted, attention must be given to the

t r e a t m e n t o f t h e r a w w a t e r u s ed a s m a ke - u p s o t h a t a n

accumulation of unwanted materials or corrosion does not occur.

For more information, contact your local Cleaver-Brooks authorized

representative.

On a hot water system, chemical cleaning is generally necessary

and the entire system should be drained after treatment. Consult

Содержание CB Ohio Special 100 HP

Страница 2: ...ii ...

Страница 8: ...viii ...

Страница 42: ...Chapter 2 Burner Operation and Control 2 22 Part No 750 184 ...

Страница 116: ...Chapter 6 Adjustment Procedures 6 28 Part No 750 184 ...

Страница 126: ...Chapter 8 Inspection and Maintenance 8 6 Part No 750 184 ...

Страница 153: ...Chapter 9 Parts Part No 750 184 9 3 Insulated Front Head Model CB LE ...

Страница 154: ...Chapter 9 Parts 9 4 Part No 750 184 Insulated Front Head Interior Model CB LE ...

Страница 155: ...Chapter 9 Parts Part No 750 184 9 5 Insulated Inner Door Model CB OS ...

Страница 156: ...Chapter 9 Parts 9 6 Part No 750 184 Insulated Rear Head CB LE ...

Страница 157: ...Chapter 9 Parts Part No 750 184 9 7 Insulated Rear Head CB LE ...

Страница 158: ...Chapter 9 Parts 9 8 Part No 750 184 Insulated Rear Head CB OS ...

Страница 159: ...Chapter 9 Parts Part No 750 184 9 9 Dry Oven Model CB LE ...

Страница 161: ...Chapter 9 Parts Part No 750 184 9 11 Motor Impeller Model CB LE ...

Страница 162: ...Chapter 9 Parts 9 12 Part No 750 184 Front Head Linkage ...

Страница 170: ...Chapter 9 Parts 9 20 Part No 750 184 Control Cabinet Hawk ICS ...

Страница 171: ...Chapter 9 Parts Part No 750 184 9 21 Control Panel Standard ...

Страница 172: ...Chapter 9 Parts 9 22 Part No 750 184 Entrance Box ...

Страница 173: ...Chapter 9 Parts Part No 750 184 9 23 Front Head Electrical CB LE ...

Страница 174: ...Chapter 9 Parts 9 24 Part No 750 184 Front Head Electrical CB LE ...

Страница 175: ...Chapter 9 Parts Part No 750 184 9 25 Front Head Electrical CB OS ...

Страница 176: ...Chapter 9 Parts 9 26 Part No 750 184 Front Head Electrical CB OS ...

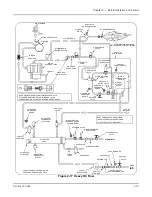

Страница 179: ...Chapter 9 Parts Part No 750 184 9 29 Heavy Oil Piping 60 Steam CB LE ...

Страница 180: ...Chapter 9 Parts 9 30 Part No 750 184 Heavy Oil Piping 60 Steam CB LE SEE TABLE NEXT PAGE ...

Страница 181: ...Chapter 9 Parts Part No 750 184 9 31 Common Oil Parts Heavy Oil ...

Страница 182: ...Chapter 9 Parts 9 32 Part No 750 184 Side Mounted Air Compressor Piping ...

Страница 183: ...Chapter 9 Parts Part No 750 184 9 33 Air Compressor Piping CB OS ...

Страница 185: ...Chapter 9 Parts Part No 750 184 9 35 Light Oil Piping ...

Страница 186: ...Chapter 9 Parts 9 36 Part No 750 184 Light Oil Air Piping Front Head ...

Страница 187: ...Chapter 9 Parts Part No 750 184 9 37 Light Oil Air Piping Front Head PAGE 9 31 ...

Страница 191: ...Chapter 9 Parts Part No 750 184 9 41 Gas Train 125 150 HP ...

Страница 193: ...Chapter 9 Parts Part No 750 184 9 43 Gas Train 200 HP ...

Страница 195: ...Chapter 9 Parts Part No 750 184 9 45 Steam Pressure Controls ...

Страница 196: ...Chapter 9 Parts 9 46 Part No 750 184 Hot Water Temperature Controls ...

Страница 197: ...Chapter 9 Parts Part No 750 184 9 47 Water Column ...

Страница 198: ...Chapter 9 Parts 9 48 Part No 750 184 Water Column ...

Страница 199: ...Chapter 9 Parts Part No 750 184 9 49 Fireside Gaskets CB LE ...

Страница 200: ...Chapter 9 Parts 9 50 Part No 750 184 Fireside Gaskets CB OS ...