Recovery System

36

Service Manual – Clarke CA30 20B and 17E

Troubleshooting

The following sections present some common troubleshooting scenarios based on symptom.

Warning!

Risk of electrical shock. Some of the procedures below require examining parts of the

machine while electrical power is present. Use care when examining or troubleshooting the

machine when power is present. Always disconnect power from the machine before and

after these examinations are performed.

Vacuum Motor (17E)

The vacuum motor circuit gets it power from the main power switch, which then passes through a 5-amp

circuit breaker before reaching the motor. The vacuum motor has brushes, which may also be a cause of

motor failure.

•

Check the vacuum 5-amp circuit breaker for trip by pressing in on the button.

•

Remove the control panel and check for line voltage across both pair of terminals on the vacuum switch

when the switch is in the on-position. If not, replace the switch.

•

Inspect the motor brushes and replace if necessary. (See

Vacuum Motor Brushes

described on page 39.)

Vacuum Motor (20B)

The vacuum motor circuit gets its positive-power from the control board, and negative-power direct from

the battery disconnect. Failure of the vacuum motor can generally be isolated to 1 of 3 areas: motor brushes,

control board failure, or switch failure. The brushes may be the most likely cause, but it is easiest to

eliminate other causes before disassembling the machine.

1. Verify that the vacuum switch is functioning by performing the procedure

Power, Vacuum, Solution, and

Brush Switches

described on page 25.

2. Check the voltage from the control board when the vacuum should normally be running. The voltage

between the “Vac Motor” terminal and “GND” terminal should be 24 volts. If 24 volts is not present,

replace the control board.

3. Remove the vacuum motor from the machine (a prerequisite to replacing the motor brushes), and check

the voltage at the motor. If 24 volts is present, then replace the brushes as described on

page 39

.

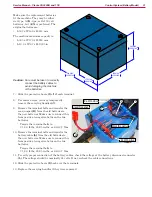

Weak Suction

The most common cause for weak suction is a vacuum leak, but it may also be caused by a blockage.

•

A blockage can be identified as the cause if the vacuum pressure feels weak when air is flowing, but feels

strong when completely blocked (high static pressure). If a blockage is suspected:

•

Inspect and clean the float/filter canister in the recovery tank.

•

Inspect the suction lines for obstruction.

•

A vacuum leak can be identified as the cause if the vacuum pressure is low when blocked or unblocked. If

a vacuum leak is suspected:

•

Make sure the recovery tank cover is properly closed and seated.

•

Make sure the recovery tank cover gasket is not damaged or torn.

•

Make sure the recovery tank drain hose is not open.

•

Inspect the squeegee suction hose for tears or holes.

•

Inspect the squeegee blades for tears, and proper trim adjustment (

page 58

).

•

Inspect the vacuum suction hose between the vacuum motor and recovery tank.