- 23 -

© 2014 Chromalox

®

, Inc.

1-888-996-9258

1. Set Current Limit (I LIM) pot to 0% for full current output (CCW).

Current Limit is for limiting current for loads that have

extreme hot to cold resistance ratios or are overrated. We

recommend for these types of loads to adjust I LIM (Cur

-

rent Limit) to 50% or less. This will also decrease voltage

as well as current. 0% Current Limit gives 100% current

output (CCW). 100% Current Limit gives 10% current

output (CW).

2. Set Manual (MAN) pot to zero so unit will not be biased above

input (CCW).

Manual control adjustment provides a means of setting

the output level of the MaxPac Power Pak in the absence

of controlling instrumentation. The manual control signal

value “adds” to the controlling instrument to set mini

-

mum output. The desired output power level may be set

by adjusting the manual control. This value of output will

then be present even in the absence of a control signal.

3. Set Remote Manual pot to zero output so unit will not be biased

above input (CCW). (Jumper pins 4 & 5 if not used.)

Remote Manual control adjustment provides a means

of setting the output level of the MaxPac Power Pak in

the absence of controlling instrumentation. The Remote

Manual control is also effective when a control signal

is connected. The Remote Manual control signal value

“adds” to the controlling instrument to set minimum

output. The desired output power level may be set by

adjusting the Remote Manual control. This value of out

-

put will then be present even in the absence of a control

signal. Connect Remote Manual pot wire to Pin 4 (CCW),

Pin 5 (W), and Pin 6 (CW) of plug-in connector.

4. Check for open contact for Emergency Shutdown.

Emergency Shutdown inhibits all SCR trigger pulses

regardless of the level of the input signal or manual

potentiometer. For Emergency Shutdown, close contact

Pin 7 to Pin 8 of plug-in connector. Leave contacts open

for operation.

5. Check for polarity of input signal.

6. Adjust input signal to low end of scale.

Zero Adjust control sets the power output starting point

or reference. Thus, it effectively cancels positive inputs

to the MaxPac Power Pak.

EXAMPLE: 0 - 5 mA input à set to 0 mA input

4 - 20 mA input à set to 4 mA input

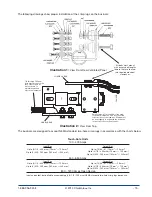

7. With power off, connect line voltage and load as shown.

8. Connect meter to input and output.

WARNING: Set meter to correct scale to read proper input

or output.

9. Apply power to unit.

10. Adjust input signal to low end of scale.

11. Using the Zero pot, adjust the output voltage just to zero volts.

12. Adjust input signal to top end of scale.

Gain Adjust Control sets the maximum power output for

maximum input signal.

EXAMPLE: 0 - 5 mA input: set to 5 mA input

4 - 20 mA input: set to 20 mA input

13. Using the Gain pot, adjust output voltage just to maximum

volts.

14. Repeat steps 11, 12, 13, and 14 until no adjustment is

necessary of Zero and Gain pots for proper output voltage

indication. Voltage output should increase proportionally to the

signal input applied.

15. Adjust input signal to low end of scale (zero voltage output).

16. With Manual pot at zero for zero voltage output, adjust (CW)

to 100% for full voltage output. Voltage output should

increase proportionally. Return to CCW position and output will

decrease to zero output.

17. With Remote Manual at zero for zero voltage output, adjust

(CW) to 100% for full voltage output. Voltage output should

increase proportionally. Return to CCW position and output will

decrease to zero output.

18. With Manual pot (CW) at 100% and I LIM (Current Limit) at

0%,

adjust I LIM towards 100% noting that voltage

output de

creases with the adjustment of the

Current Limit pot. Adjust

Current Limit pot for your

application, if needed.

19. Turn POWER OFF and remove meters. TEST COMPLETE.

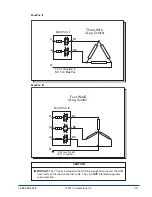

4.2.6 - Calibration (MaxPac IP):

Many high-temperature heating elements exhibit extreme hot to cold resistance ratios. Heating elements composed of Platinum,

Molybdenum, Tungsten, and Tantalum, to name a few, draw excessive current on start-up. Depending on the mass of the elements,

these “high starting currents” may exist for extended periods of time. Generally, once the elements have achieved their normal operat

-

ing temperatures, the current drawn through the MaxPac Power Pak will fall within the rating of the unit. For these types of loads, we

recommend adjusting the I LIM (Current Limit) to 50% or less. This will decrease voltage as well as current.