Chapter

5Maintenance and Checkup

58

5.6.2

Error/Warning Table

Priority

Error No.

Error/warning

Description

ERROR

lamp

Device

operation

Action

High

Low

ERR03

Rotational

frequency

error

Motor is not running.

Lit

Remains

operational

Follow the remedies for

②

in

(

Page 59

).

ERR04

Internal

temperature

error

Temperature around the

blower is too high.

Lit

Stop

Follow the remedies for

②

in

(

Page 59

).

ERR06 Pressure error

Operation continued at

low pressure for more

than preset period.

Lit

Stop

Follow the remedies for

②

in

(

Page 59

).

ERR07

F-RAM write

error

Cannot write to F-RAM. Flashing

Remains

operational

Contact CHIKO AIRTEC.

ERR08

Communication

error

BCC judgment

mismatch

Flashing

Remains

operational

Contact CHIKO AIRTEC.

WARN1

Internal

temperature

high

Temperature around the

blower is close to the

error threshold.

Flashing

Remains

operational

Follow the remedies for

②

in

(

Page 59

).

WARN2

Filter

replacement

time limit

expired

Operation continued at

low air volume for more

than preset period.

Flashing

Remains

operational

Follow the remedies for

③

in

(

Page 59

).

WARN3

Inadequate

pressure

(suction)

Suction pressure is low. Flashing

Remains

operational

Follow the remedies for

②

in

(

Page 59

).

WARN4

Inadequate air

volume

Air volume is reduced by

filter clogging.

Flashing

Remains

operational

Follow the remedies for

③

in

(

Page 59

).

WARN5

Exhaust

pressure error

Exhaust pressure is too

high.

Flashing

Remains

operational

Follow the remedies for

③

or

④

in

(

Page 59

).

WARN6

Initial pressure

unregistered

Initial pressure is not

registered yet.

Flashing

Remains

operational

Register initial pressures.

(

Page 48)

WARN7

Battery

voltage low

Remaining battery level

is low.

Flashing

Remains

operational

Replace the button battery.

(

Page 55)

Содержание CBA-1500AT3-HC-DSA-V1

Страница 5: ...1 CMN023 005 Translation of the original instructions 3 1 1 1 1 2 10 60 80 1 3 0 40 80 100 1 000...

Страница 6: ...1 4 1 4 2 OFF 1 5...

Страница 7: ...1 CMN023 005 Translation of the original instructions 5 1 6...

Страница 8: ...2 6 2 2 1 200V 220 230V CE 1 1 2 1 1 HEPA 1 3m 200V 1 220 230V CE 1 1...

Страница 10: ...2 8 2 3 AT3 EL OLED No 1 7 2 4 9 4 15 1 1 1 1 OFF 3 3 3 14 ON ENTER 3 3 3 14 4 15 MODE SELECT 4 15...

Страница 12: ...2 10 2 4 3 OP kPa SP kPa DP kPa EP kPa Blower Runtime h 18 Total h Moter...

Страница 13: ...3 CMN023 005 Translation of the original instructions 11 3 3 1 3 1 1 0 40 80 RH REMOVE 1 1 1...

Страница 14: ...3 12 1 2 2 3 4 OFF ON 1 A OFF 40 50 A 2...

Страница 22: ...5 20 5 5 1 WARN2 1 5 1 1 1 1 1 2 2 1 3 1 4 2 1...

Страница 24: ...5 22 3 ACC 4 5 6 5 2 1 Littell fuse 218 250V 15A 1 2 3 ACC...

Страница 25: ...5 CMN023 005 Translation of the original instructions 23 5 3 CR2477 CR2477 1 2 3 2 4 5 6 7 5 4 1 1 1 1 5 5...

Страница 28: ...5 26 5 7 EL ON ON 5 2 22 1 2 3 4 1 4 ON OFF 30 1 2 1 2 5 1 20 5 1 20 5 1 20 5 1 20...

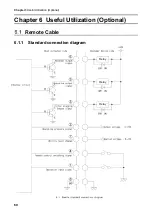

Страница 29: ...6 CMN023 005 Translation of the original instructions 27 6 6 1 6 1 1...

Страница 30: ...6 28 1 5V 0 2V LOW DC 1 2...

Страница 34: ...7 32 7 3 7 3 1 CBA 1500AT3 HC DSA V1...

Страница 35: ...CMN023 005 Translation of the original instructions 33 12 7 2 7 2 31...

Страница 36: ...34...

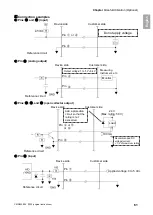

Страница 67: ...Chapter 7Appendix CMN023 005 original instructions 65 English Electrical Diagram 7 3 1 CBA 1500AT3 HC DSA V1...

Страница 69: ...MEMO...