Chapter

3Operation

48

Registering Initial Pressures

Air volume reduction due to filter clogging is judged based on a registered initial differential pressure and

indicated as low air volume (WARN4). Register initial pressures through these steps:

1.

Perform the wiring and piping of the device.

2.

Start the device at a desired suction power level.

3.

Press and hold down the ENTER button for three seconds.

The display shows “Initial DP Get Y”, prompting confirmation to register/update initial pressures.

4.

To proceed with registration/update, press the ENTER button.

The device starts to acquire initial pressure.

If you do not want update, press the MODE SELECT button to return to normal operation.

5.

The device runs through a sequence of suction power levels 1 to 7, to automatically acquire the

differential pressure for each level.

While the device is acquiring initial pressures, the display alternates between the “Initial DP Check

Entry” message and the “suction power level and differential pressure” values.

6.

When the registration completes, the display shows the “Initial DP Entry” message and the device

returns to normal operation.

IMPORTANT

•

Ensure that the filters are new.

•

Update registered initial pressures once again if piping is changed or all filters are

replaced (except for the exhaust filter) after registration of initial pressures.

•

If initial pressures are not registered, an “initial pressure unregistered” warning

(WARN6) appears.

•

The registered initial pressures can be cleared by holding down the OFF button for

three seconds when the device is in stop state.

●

Clearing registered initial pressures

1.

Hold down the OFF button for three seconds when the device is in stop state.

The display shows “Initial DP Clr Y”, prompting confirmation to clear registered initial pressures.

2.

To clear them, press the ENTER button.

If you do not want to clear them, press the MODE SELECT button to return to normal operation.

3.

When the clearing completes, the display shows the “Initial DP Clr” message and the device

returns to the stop state.

Содержание CBA-1500AT3-HC-DSA-V1

Страница 5: ...1 CMN023 005 Translation of the original instructions 3 1 1 1 1 2 10 60 80 1 3 0 40 80 100 1 000...

Страница 6: ...1 4 1 4 2 OFF 1 5...

Страница 7: ...1 CMN023 005 Translation of the original instructions 5 1 6...

Страница 8: ...2 6 2 2 1 200V 220 230V CE 1 1 2 1 1 HEPA 1 3m 200V 1 220 230V CE 1 1...

Страница 10: ...2 8 2 3 AT3 EL OLED No 1 7 2 4 9 4 15 1 1 1 1 OFF 3 3 3 14 ON ENTER 3 3 3 14 4 15 MODE SELECT 4 15...

Страница 12: ...2 10 2 4 3 OP kPa SP kPa DP kPa EP kPa Blower Runtime h 18 Total h Moter...

Страница 13: ...3 CMN023 005 Translation of the original instructions 11 3 3 1 3 1 1 0 40 80 RH REMOVE 1 1 1...

Страница 14: ...3 12 1 2 2 3 4 OFF ON 1 A OFF 40 50 A 2...

Страница 22: ...5 20 5 5 1 WARN2 1 5 1 1 1 1 1 2 2 1 3 1 4 2 1...

Страница 24: ...5 22 3 ACC 4 5 6 5 2 1 Littell fuse 218 250V 15A 1 2 3 ACC...

Страница 25: ...5 CMN023 005 Translation of the original instructions 23 5 3 CR2477 CR2477 1 2 3 2 4 5 6 7 5 4 1 1 1 1 5 5...

Страница 28: ...5 26 5 7 EL ON ON 5 2 22 1 2 3 4 1 4 ON OFF 30 1 2 1 2 5 1 20 5 1 20 5 1 20 5 1 20...

Страница 29: ...6 CMN023 005 Translation of the original instructions 27 6 6 1 6 1 1...

Страница 30: ...6 28 1 5V 0 2V LOW DC 1 2...

Страница 34: ...7 32 7 3 7 3 1 CBA 1500AT3 HC DSA V1...

Страница 35: ...CMN023 005 Translation of the original instructions 33 12 7 2 7 2 31...

Страница 36: ...34...

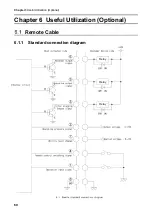

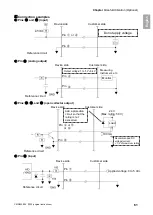

Страница 67: ...Chapter 7Appendix CMN023 005 original instructions 65 English Electrical Diagram 7 3 1 CBA 1500AT3 HC DSA V1...

Страница 69: ...MEMO...