チコーエアーテック株式会社

Copyright CHIKO AIRTEC CO., LTD. 2009

12

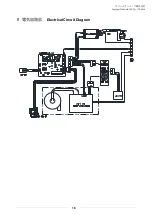

5.2

各線の色と信号について

Color and signal of each wire

入力

INPUT

:① 接点入力

(無電圧接点

)

Contact input (no-voltage contact)

インピーダンス

Impedance

1.0

k

Ω

出力

OUTPUT

:②~⑥オープンコレクタ

Open collector

耐圧

Voltage resistance 50

V (≦

100 mA

)

入力電圧範囲 :⑦ 電圧入力

0

~

5V

Input voltage range:

⑦

Voltage input of 0 to 5V

インピーダンス

10.0

kΩ ※

+5.0V

以上印加させないでください。

Impedance:10.0k

Ω ※

Do not apply voltage exceeding

+

5.0V.

※誤差が±

4%

ある為、電圧を設定する際は、各レベルの中点の

電圧を印加してください。

※

When setting the voltage,apply a mid-point voltage value for

each level since the error range is

±

4%.

線色

Wire color

PIN

NO.

信号名称

Signal

name

役割

Role

黒

Black

①

運転入力信号

Operation input signal

遠隔信号

(

入力

)

Rem

o

te

s

ig

n

a

ls

④⑧を短絡後、①を短絡して運転を開始します

After short-circuiting pins(4) and(8),short-circuit

pin(1)to start operation.

赤

/

白

Red/white

④

遠隔操作切替信号

Remote-control operation

switching signal

④と⑧を短絡してリモート操作に移行させます

短絡するとタッチパネルの操作はできなくなります

Short-circuits the wires [4] and [8] to start remote operation.

The AT panel is disabled while the wires [4] and [8] are

short-circuited.

黄

Yellow

⑦

能力レベル変更

Change capacity level

⑦と⑧の間で、

0~5

Vの電圧を印加する事で能力レベル

を変更することが出来ます。

The capacity level can be changed by applying a

voltage of 0 to 5V between pins(7) and(8).

黄

/

白

Yellow /white

⑧

Gnd

黒

/

白

Black/White

②

運転圧力信号

Operation pressure signal

出力信号

O

u

tp

u

t

s

ig

n

a

ls

現在の運転圧力を取り出します

Transfers the current operation output.

アナログ信号

Analog signal

(

1

~

5V

)

インピーダンス

Impedance

(≧

4.7

kΩ)

赤

Red

③

風量不足信号

Air flow shortage

signal

Insufficient airflow signal

風量低下信号を取り出します

Outputs an insufficient airflow signal.

Transfers the

”

Air flow shortage

“ signal

オープンコレクタ出力;

NPN

Open collector output

緑

Green

⑤

運転出力信号

Operation output signal

運転信号(ONランプ)を取り出します

Transfers the operation signal (ON indicator lamp).

オープンコレクタ出力

Open collector output

緑

/

白

Green/White

⑥

圧力不足出力信号

Pressure down output signal

圧力不足信号を取り出します

Transfers the

” pressure down “ signal

オープンコレクタ出力

Open collector output

能力レベル

Capacity level

電圧

(DCV)

Voltage(VDC)

1

0.6

~

1.1

2

1.2

~

1.7

3

1.8

~

2.3

4

2.4

~

2.9

5

3.0

~

3.5

6

3.6

~

4.1

7

4.2

~

5.0

電圧

(DC

V)

1

2

3

4

5

6

7

能力レベル

1

0

2

3

4

5

6

7

1

2

3

4

5

6