S e c . 7B

P a g e 46

T RA N SM ISSIO N ON-VEHICLE SERVICE

NOTE: Pull secondary w ire out of center

so ck et in the distributor cap and ground w ire to

prevent p o ssib le dam age to co il.

2. P o sitio n s e le c to r le v e r in "N" (Neutral).

Turn ignition sw itch to "START" position. Engine

should sta rt but v eh icle must not m ove. Turn ig

nition sw itch to "OFF."

3. P o sitio n s e le c to r le v e r in "R" (R everse).

Turn ignition sw itch to "START" position. Engine

m ust not sta rt.

4. Move s e le c to r le v e r to "D" (Drive) p o s i

tion. Engine m ust not sta rt.

5. If the previou s conditions are not met for

the neutral sa fety and back-up lamp switch,adjust

the sw iv el p osition on rod (H) until operation is as

stated in Steps 2 -4 .

DOWNSHIFT SWITCH ADJUSTMENT

NOTE: The downshift sw itch mounted at the

carburetor is activated by the carburetor throttle

le v e r . When the throttle le v e r rea ch es wide open

p o sitio n it r e su lts in a forced downshift to the

tr a n sm issio n u n less veh icle is in "LI."

1. Move carburetor throttle le v e r to wide

open p osition .

2. L oosen two adjusting sc r e w s (at slotted

holes) on sw itch bracket.

3. P o sitio n sw itch and bracket a ssem b ly so

that clea ra n ce betw een throttle le v e r and sw itch

plunger (fully d ep ressed ) is .05-in ch .

4. Tighten the two adjusting s c r e w s to 20-30

inch-pounds torque.

5. Road te st and check for proper operation.

SECTION 7B

On-Velude Sendee. Op&uuUo-HA,

AT475 T RA N SM ISSIO N

REPLACEMENT

The follow ing p roced u res apply to veh icles

covered by this supplem ent. H owever, it may be

n e c e ssa r y to rem ove air tanks, fuel tanks, special

equipm ent, e tc ., on som e v eh icles to provide

cle a ra n ce b efore the tra n sm issio n is rem oved.

Overhaul inform ation for the AT475 tra n s

m is s io n is contained in 40-6 0 S e r ie s Truck Chas

s i s O verhaul Manual Supplem ent S T -334-72.

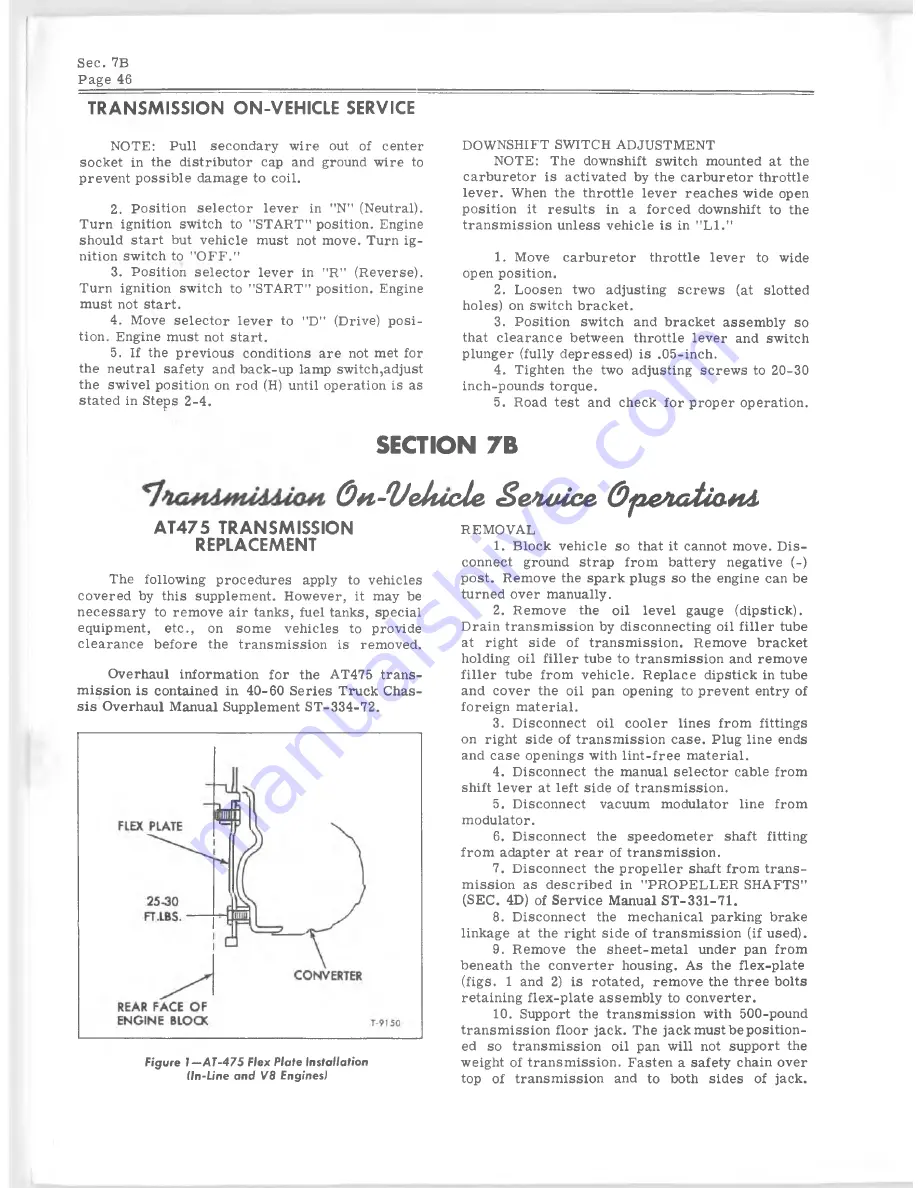

Figure l - A T - 4 7 5 Flex Plate Installation

(In-Line an d V8 Engines)

REMOVAL

1. B lock v eh ic le so that it cannot m ove. D is

connect ground strap from battery negative (-)

p o st. R em ove the spark plugs so the engine can be

turned over m anually.

2. R em ove the o il le v e l gauge (dipstick).

D rain tr a n sm issio n by disconnecting o il f ille r tube

at right sid e of tra n sm issio n . R em ove bracket

holding o il fille r tube to tr a n sm issio n and rem ove

fille r tube from v e h ic le . R eplace dipstick in tube

and cover the o il pan opening to prevent entry of

foreign m aterial.

3. D iscon n ect o il c o o ler lin es from fittin gs

on right sid e of tr a n sm issio n c a se . Plug lin e ends

and c a se openings with lin t-fr e e m aterial.

4. D iscon n ect the manual se le c to r cable from

shift le v e r at left sid e of tr a n sm issio n .

5. D isconnect vacuum modulator lin e from

m odulator.

6. D iscon n ect the sp eed om eter shaft fitting

from adapter at rear of tr a n sm issio n .

7. D iscon n ect the p ro p eller shaft from tra n s

m issio n as d escrib ed in "PROPELLER SHAFTS"

(SEC. 4D) of S erv ice Manual S T -331-71.

8. D iscon n ect the m echanical parking brake

linkage at the right sid e of tr a n sm issio n (if used).

9. Rem ove the sh e e t-m e ta l under pan from

beneath the con verter housing. A s the flex -p la te

(fig s. 1 and 2) is rotated, rem ove the three bolts

retaining fle x -p la te a ssem b ly to con verter.

10. Support the tr a n sm issio n with 500-pound

tr a n sm issio n floor jack. The jack m ust be p o sitio n

ed so tr a n sm issio n o il pan w ill not support the

w eight of tr a n sm issio n . F asten a safety chain over

top of tr a n sm issio n and to both sid e s of jack.