HEATER AND AIR CONDITIONING 1A-23

add the same amount of new refrigerant oil to the

replacement compressor.

b. If the quantity drained was less than 4 fluid oz.,

add 6 fluid oz. of new refrigeration oil to the

replacement compressor.

c. If a new service compressor is being installed,

drain all oil from it and replace only the amount

specified in Steps 3a and 3b above.

d. If a field repaired compressor is being installed,

add an additional 1 fluid oz. to the compressor.

4. In the event that it is not possible to idle the com

pressor as outlined in Step 1 to effect oil return to

it, proceed as follows:

a. Remove the compressor, drain, measure and

discard the oil.

b. If the amount drained is more than 1-1/2 fluid

oz. and the system shows no signs of a major

leak, add the same amount to the replacement

compressor.

c. If the amount drained is less than 1-1/2 oz. and

COMPONENT REPLACEMENT

ALL SYSTEMS

PREPARING SYSTEM FOR

REPLACEMENT OF CO M PO NEN T PARTS

Air conditioning, like many other things, is fairly simple

to service once it is understood. However, there are

certain procedures, practices and precautions that should

be followed to prevent costly repairs, personal injury

or damage to equipment. For this reason it is strongly

recommended that the preceding information in this sec

tion be studied thoroughly before attempting to service

the system.

Great emphasis must be placed upon keeping the sys

tem clean.

Use plugs or caps to close system com

ponents and hoses when they are opened to the atmos

phere. Keep your work area clean.

In removing and replacing any part which requires

unsealing the refrigerant circuit the following operations,

which are described in this section, must be performed

in the sequence shown.

1. Purge the system by releasing the refrigerant to the

atmosphere.

2. Remove and replace the defective part.

3. Evacuate and charge the system.

CAUTION:

Always wear protective goggles

when working on refrigeration systems. Goggles

J-5453 are included in the set of air conditioning

special tools.

Also, beware of the danger of

carbon monoxide fumes by avoiding running the

engine in closed or improperly ventilated

garages.

FOREIGN MATERIAL IN THE SYSTEM

Whenever foreign material is found in the system, it

must be removed before restoring the system to opera

tion.

In the case of compressor mechanical failure, per

form the following operations:

1. Remove the compressor.

2. Remove the receiver-dehydrator and discard the unit.

3. Flush the condenser to remove foreign material

which has been pumped into it.

the system appears to have lost an excessive

amount of oil, add 6 fluid oz. of clean refrigera

tion oil to replacement compressor, 7 fluid oz. to

a repaired compressor.

If the oil contains chips or other foreign ma

terial, replace the receiver-dehydrator and flush

or replace all component parts as necessary. Add

the full 11 fluid oz. of new refrigeration oil to the

replacement compressor.

5. Add additional oil in the following amounts for any

system components being replaced.

Evaporator Core..................................

3 fluid oz.

Condenser............................................

1 fluid oz.

Receiver-Dehydrator...........................

1 fluid oz.

NOTE:

When adding oil to the compressor, it

will be necessary to tilt the rear end of the

compressor up so that the oil will not run out

of the suction and discharge ports. Do not set

the compressor on the shaft end.

A N D M IN O R REPAIR

Disconnect the line from the receiver-dehydrator

at the inlet connection of the expansion valve. Inspect

the inlet screen for the presence of metal chips or

other foreign material.

If the screen is plugged,

replace it.

Reconnect the line to the expansion

valve.

5. Install a new receiver-dehydrator.

6. Install the replacement compressor.

7. Add the necessary quantity of oil to the system (one

fluid ounce because of receiver-dehydrator replace

ment plus the quantity needed for the replacement

compressor -

see "Checking Compressor Oil

Charge" under "Checking Oil."

8. Evacuate and charge the system.

9. Check system performance.

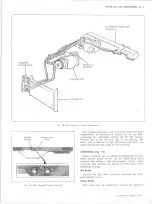

REFRIGERANT LINE CO NNECTIO NS

“O ” Rings

Always replace the "O" ring when a connection has

been broken. When replacing the "O" ring, first dip it

in clean refrigeration oil. Always use a backing wrench

on "O" ring fittings to prevent the pipe from twisting and

damaging the "O" ring. Do not overtighten. Correct

torque specifications are as follows:

Metal

Tube

O.D.

Thread and

Fitting

Size

Steel

Tubing

Torque*

Alum.

Tubing

Torque*

1/4

7/16

13

6

3/8

5/8

33

12

1/2

3/4

33

12

5/8

7/8

33

20

3/4

1-1/16

33

25

*Foot Pounds.

NOTE:

Where steel to aluminum connections

are being made, use torque for aluminum tubing.

Hose Clamps

When hose clamp connections are encounted, special

10-30 CHEVROLET TRUCK SERVICE MANUAL

Содержание 10 1971 Series

Страница 1: ......

Страница 96: ......

Страница 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Страница 120: ......

Страница 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 218: ......

Страница 249: ......

Страница 250: ...EMISSION CONTROL SYSTEMS 6T 4 Fig 3 Combination Emission Control System Routing V8 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 324: ......

Страница 339: ...FUEL TANK AND EXHAUST SYSTEMS 8 15 SPECIAL TOOLS Fig 22 Special Tools 1 J 23346 Fuel Tank Gauge Remover and Installer ...

Страница 340: ......

Страница 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Страница 368: ......

Страница 386: ......

Страница 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 391: ......

Страница 392: ...ELECTRICAL BODY AND CHASSIS 12 6 Fig 5 Rear Lighting Composite 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 409: ...ELECTRICAL BODY AND CHASSIS 12 23 Fig 27 Engine Compartment CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 410: ...ELECTRICAL BODY AND CHASSIS 12 24 18DK GRN 19 Fig 28 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 411: ...ELECTRICAL BODY AND CHASSIS 12 25 Fig 29 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 412: ...ELECTRICAL BODY AND CHASSIS 12 26 fh Ar r kk 4 Fig 30 Engine Compartment C A K A 10 20 CA30 03 z _ ...

Страница 416: ...ELECTRICAL BODY AND CHASSIS 12 30 Fig 34 Engine Compartment CA KA10 20 CA30 04 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 420: ...ELECTRICAL BODY AND CHASSIS 12 34 Fig 38 Engine Compartment C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 422: ...ELECTRICAL BODY AND CHASSIS 12 36 Fig 40 Instrument Panel C A K A 10 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 423: ...ELECTRICAL BODY AND CHASSIS 12 37 Fig 41 R ear Lamps C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 424: ...ELECTRICAL BODY AND CHASSIS 12 38 Fig 42 Engine Compartment CA KA10 20 CAl30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 426: ...ELECTRICAL BODY AND CHASSIS 12 40 Fig 44 Instrument Panel CA KA10 20 CA30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 428: ......

Страница 432: ......

Страница 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 463: ......

Страница 464: ......

Страница 465: ......

Страница 466: ......