HEATER AND AIR CONDITIONING 1A-20

POORLY LOCATED POWER ELEMENT BULB

Normal Pressure.

Poor Cooling.

Check for Defective Valve

The following procedure must be followed to determine

if a malfunction is due to a defective expansion valve.

1. Check to determine if the system will meet the per

formance test as outlined previously. If the expan

sion valve is defective, the low pressure readings

(POA or evaporator pressure) will be above specifi

cation.

2. The loss of system performance is not as evident

when the compressor head pressure is below 200 PSI.

Therefore, it may be necessary to increase the sys

tem head pressure by partially blocking the conden

ser. Disconnect the blower lead wire and repeat the

“ Peformance Check" to determine if the evaporator

pressure can be obtained.

3. The system will also indicate a low refrigerant

charge by bubbles occurring in the sight glass.

Systems equipped with a POA Valve require the

following additional test to determine if the de

ficiency is the expansion valve.

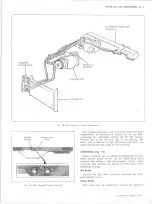

4. Remove the expansion valve bulb from the evaporator

outlet pipe, and the connector on the blower resistor.

Place the blower on "low." With the engine operat

ing at 2,000 rpm, observe the POA gauge pressure.

5. Insert the expansion valve bulb in a cup of ice. This

should result in the POA pressure being reduced

to approximately 30 P.S.I. If the pressure does not

reduce to this level, the POA valve is defective. If

the pressure falls considerably below 30 P.S.I., the

expansion valve is defective.

ENGINE IDLE CO MPENSATOR

This additional aid to prevent stalling during prolonged

hot weather periods is included with all air conditioned

vehicles.

The idle compensator is a thermostatically

controlled air bleed which supplies additional air to the

idle mixture. On V-8 engines, with factory installed air

conditioning systems, the compensator is located within

the carburetor and is accessible when the engine air

cleaner is removed. On all other vehicles the compen

sator is threaded into a manifold fitting below the car

buretor. All compensators are factory set and are non-

adjustable.

A malfunctioning unit should be replaced.

NOTE:

If engine idle is erratic, hold the idle

compensator valve closed with a pencil or

wooden dowel while adjusting the idle mixture

screw(s). Never attempt to bend the bimetal

strip or attempt any valve adjustment.

EVACUATING A N D CH ARG ING PROCEDURES

AIR C O N D IT IO N IN G SYSTEM CAPACITY

Refrigerant

Charge

Oil Charge

Four-Season System 3 lbs. 4 oz.

10 oz. 525 Viscosity

Roof-Mounted

4 lbs. 8 oz.

13 oz. 525 Viscosity

GM Chevrolet

3 lbs. 4 oz.

10 oz. 525 Viscosity

PURGING THE SYSTEM

In replacing any of the air conditioning components the

system must be completely purged or drained of re

frigerant. The purpose is to lower the pressure inside

the system so that a component part can be safely re

moved.

1. With engine stopped, install high and low pressure

lines of Charging Station gauge set to the proper

high and low pressure gauge fittings. (See "Install

ing Charging Station to Check System Operation.")

NOTE:

Before installing lines, be sure that all

four controls on the gauge set are closed.

2. Disconnect vacuum line at Charging Station vacuum

pump and lay end of line on a clean rag on the floor.

3. Crack open high (2) and low (1) pressure control

valves, and allow refrigerant to purge from system.

CAUTION:

Do not open valves too much or

compressor oil may be discharged with the re

frigerant. Oil loss can be easily detected on

rag at discharge line.

EVACUATING A N D C H A R G IN G THE SYSTEM

GENERAL NOTE:

In all evacuating proce

dures shown below, the specification of 26-28

inches of Mercury vacuum is used. These fig

ures are only attainable at or near Sea Level

Elevation. For each 1000 feet above sea level

where this operation is being performed, the

specifications should be lowered by 1 inch. Ex

ample:

at 5000 ft. elevation, only 21 to 23

inches of vacuum can normally be obtained.

Whenever the air conditioning system is open for any

reason, it should not be put into operation again until it

has been evacuated to remove air and moisture which

may have entered the system.

The following procedures are based on the use of the

J-8393 Charging Station.

Filling Charging Cylinder

1. Open valve on bottom of charging cylinder allowing

refrigerant to enter cylinder.

2. Bleed cylinder valve on top (behind control panel) as

required to allow refrigerant to enter. When refrig

erant reaches desired level (see "Air Conditioning

System Capacity"), close valve at bottom of cylinder

and be certain bleed valve is closed securely.

NOTE:

It will be necessary to close bleed

valve periodically to allow boiling to subside to

check level in sight glass.

Evacuating and Charging System

1. Install charging station and purge system as noted

10-30 CHEVROLET TRUCK SERVICE MANUAL

Содержание 10 1971 Series

Страница 1: ......

Страница 96: ......

Страница 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Страница 120: ......

Страница 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 218: ......

Страница 249: ......

Страница 250: ...EMISSION CONTROL SYSTEMS 6T 4 Fig 3 Combination Emission Control System Routing V8 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 324: ......

Страница 339: ...FUEL TANK AND EXHAUST SYSTEMS 8 15 SPECIAL TOOLS Fig 22 Special Tools 1 J 23346 Fuel Tank Gauge Remover and Installer ...

Страница 340: ......

Страница 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Страница 368: ......

Страница 386: ......

Страница 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 391: ......

Страница 392: ...ELECTRICAL BODY AND CHASSIS 12 6 Fig 5 Rear Lighting Composite 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 409: ...ELECTRICAL BODY AND CHASSIS 12 23 Fig 27 Engine Compartment CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 410: ...ELECTRICAL BODY AND CHASSIS 12 24 18DK GRN 19 Fig 28 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 411: ...ELECTRICAL BODY AND CHASSIS 12 25 Fig 29 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 412: ...ELECTRICAL BODY AND CHASSIS 12 26 fh Ar r kk 4 Fig 30 Engine Compartment C A K A 10 20 CA30 03 z _ ...

Страница 416: ...ELECTRICAL BODY AND CHASSIS 12 30 Fig 34 Engine Compartment CA KA10 20 CA30 04 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 420: ...ELECTRICAL BODY AND CHASSIS 12 34 Fig 38 Engine Compartment C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 422: ...ELECTRICAL BODY AND CHASSIS 12 36 Fig 40 Instrument Panel C A K A 10 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 423: ...ELECTRICAL BODY AND CHASSIS 12 37 Fig 41 R ear Lamps C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 424: ...ELECTRICAL BODY AND CHASSIS 12 38 Fig 42 Engine Compartment CA KA10 20 CAl30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 426: ...ELECTRICAL BODY AND CHASSIS 12 40 Fig 44 Instrument Panel CA KA10 20 CA30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 428: ......

Страница 432: ......

Страница 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 463: ......

Страница 464: ......

Страница 465: ......

Страница 466: ......