STEERING 9-19

SLEEVE

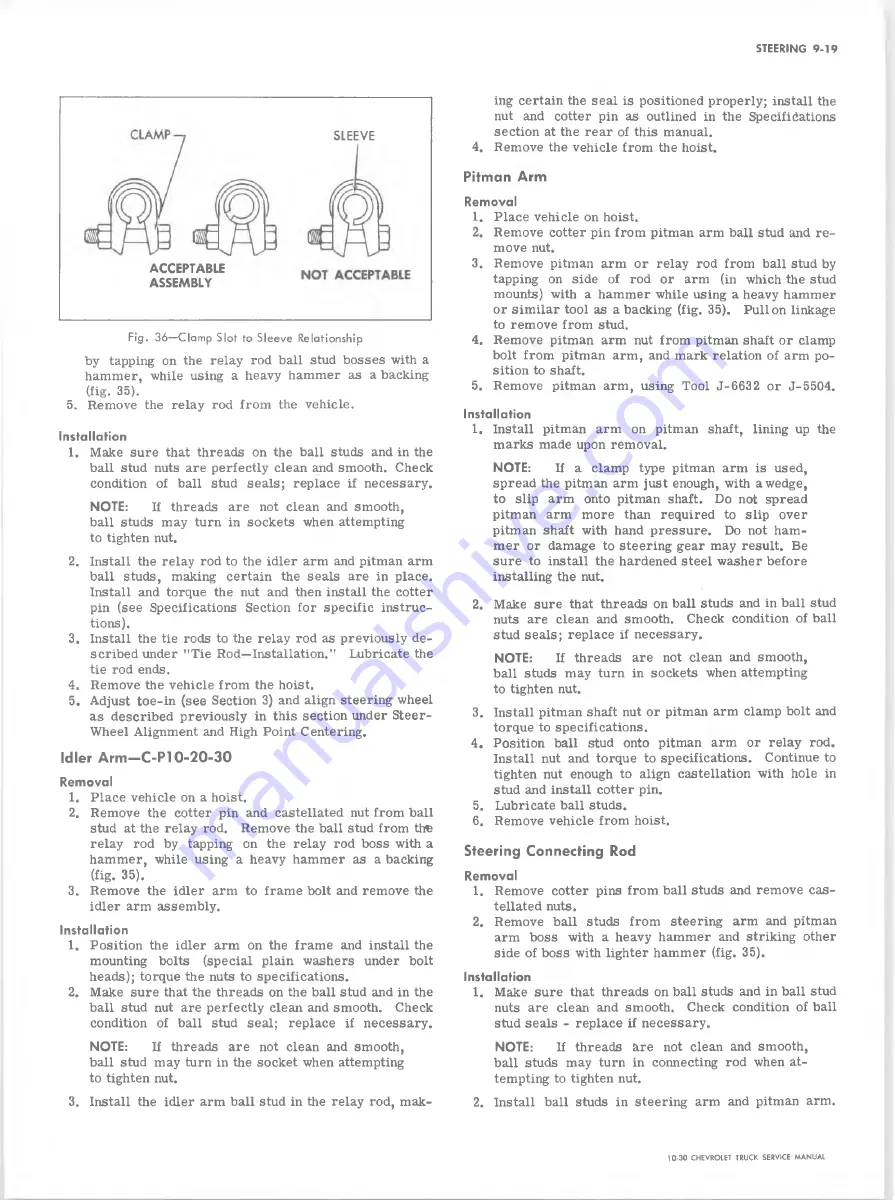

ACCEPTABLE

ASSEMBLY

Fig. 36— Clamp Slot to Sleeve Relationship

by tapping on the relay rod ball stud bosses with a

hammer, while using a heavy hammer as a backing

(fig. 35).

5. Remove the relay rod from the vehicle.

Installation

1. Make sure that threads on the ball studs and in the

ball stud nuts are perfectly clean and smooth. Check

condition of ball stud seals; replace if necessary.

NOTE:

If threads are not clean and smooth,

ball studs may turn in sockets when attempting

to tighten nut.

2. Install the relay rod to the idler arm and pitman arm

ball studs, making certain the seals are in place.

Install and torque the nut and then install the cotter

pin (see Specifications Section for specific instruc

tions).

3. Install the tie rods to the relay rod as previously de

scribed under ’’Tie Rod—Installation." Lubricate the

tie rod ends.

4. Remove the vehicle from the hoist.

5. Adjust toe-in (see Section 3) and align steering wheel

as described previously in this section under Steer-

Wheel Alignment and High Point Centering.

Idler A r m -C -P l 0-20-30

Removal

1. Place vehicle on a hoist.

2. Remove the cotter pin and castellated nut from ball

stud at the relay rod. Remove the ball stud from the

relay rod by tapping on the relay rod boss with a

hammer, while using a heavy hammer as a backing

(fig. 35).

3. Remove the idler arm to frame bolt and remove the

idler arm assembly.

Installation

1. Position the idler arm on the frame and install the

mounting bolts (special plain washers under bolt

heads); torque the nuts to specifications.

2. Make sure that the threads on the ball stud and in the

ball stud nut are perfectly clean and smooth. Check

condition of ball stud seal; replace if necessary.

NOTE:

If threads are not clean and smooth,

ball stud may turn in the socket when attempting

to tighten nut.

3. Install the idler arm ball stud in the relay rod, mak

ing certain the seal is positioned properly; install the

nut and cotter pin as outlined in the Specifications

section at the rear of this manual.

4. Remove the vehicle from the hoist.

Pitman Arm

Removal

1. Place vehicle on hoist.

2. Remove cotter pin from pitman arm ball stud and re

move nut.

3. Remove pitman arm or relay rod from ball stud by

tapping on side of rod or arm (in which the stud

mounts) with a hammer while using a heavy hammer

or similar tool as a backing (fig. 35). Pull on linkage

to remove from stud.

4. Remove pitman arm nut from pitman shaft or clamp

bolt from pitman arm, and mark relation of arm po

sition to shaft.

5. Remove pitman arm, using Tool J-6632 or J-5504.

Installation

1. Install pitman arm on pitman shaft, lining up the

marks made upon removal.

N O T E :

If a clamp type pitman arm is used,

spread the pitman arm just enough, with a wedge,

to slip arm onto pitman shaft. Do not spread

pitman arm more than required to slip over

pitman shaft with hand pressure. Do not ham

mer or damage to steering gear may result. Be

sure to install the hardened steel washer before

installing the nut.

2. Make sure that threads on ball studs and in ball stud

nuts are clean and smooth. Check condition of ball

stud seals; replace if necessary.

N O T E :

If threads are not clean and smooth,

ball studs may turn in sockets when attempting

to tighten nut.

3. Install pitman shaft nut or pitman arm clamp bolt and

torque to specifications.

4. Position ball stud onto pitman arm or relay rod.

Install nut and torque to specifications. Continue to

tighten nut enough to align castellation with hole in

stud and install cotter pin.

5. Lubricate ball studs.

6. Remove vehicle from hoist.

Steering Connecting Rod

Removal

1. Remove cotter pins from ball studs and remove cas

tellated nuts.

2. Remove ball studs from steering arm and pitman

arm boss with a heavy hammer and striking other

side of boss with lighter hammer (fig. 35).

Installation

1. Make sure that threads on ball studs and in ball stud

nuts are clean and smooth. Check condition of ball

stud seals - replace if necessary.

N O T E :

If threads are not clean and smooth,

ball studs may turn in connecting rod when at

tempting to tighten nut.

2. Install ball studs in steering arm and pitman arm.

10-30 CHEVROLET TRUCK SERVICE MANUAL

Содержание 10 1971 Series

Страница 1: ......

Страница 96: ......

Страница 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Страница 120: ......

Страница 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 218: ......

Страница 249: ......

Страница 250: ...EMISSION CONTROL SYSTEMS 6T 4 Fig 3 Combination Emission Control System Routing V8 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 324: ......

Страница 339: ...FUEL TANK AND EXHAUST SYSTEMS 8 15 SPECIAL TOOLS Fig 22 Special Tools 1 J 23346 Fuel Tank Gauge Remover and Installer ...

Страница 340: ......

Страница 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Страница 368: ......

Страница 386: ......

Страница 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 391: ......

Страница 392: ...ELECTRICAL BODY AND CHASSIS 12 6 Fig 5 Rear Lighting Composite 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 409: ...ELECTRICAL BODY AND CHASSIS 12 23 Fig 27 Engine Compartment CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 410: ...ELECTRICAL BODY AND CHASSIS 12 24 18DK GRN 19 Fig 28 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 411: ...ELECTRICAL BODY AND CHASSIS 12 25 Fig 29 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 412: ...ELECTRICAL BODY AND CHASSIS 12 26 fh Ar r kk 4 Fig 30 Engine Compartment C A K A 10 20 CA30 03 z _ ...

Страница 416: ...ELECTRICAL BODY AND CHASSIS 12 30 Fig 34 Engine Compartment CA KA10 20 CA30 04 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 420: ...ELECTRICAL BODY AND CHASSIS 12 34 Fig 38 Engine Compartment C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 422: ...ELECTRICAL BODY AND CHASSIS 12 36 Fig 40 Instrument Panel C A K A 10 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 423: ...ELECTRICAL BODY AND CHASSIS 12 37 Fig 41 R ear Lamps C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 424: ...ELECTRICAL BODY AND CHASSIS 12 38 Fig 42 Engine Compartment CA KA10 20 CAl30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 426: ...ELECTRICAL BODY AND CHASSIS 12 40 Fig 44 Instrument Panel CA KA10 20 CA30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 428: ......

Страница 432: ......

Страница 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 463: ......

Страница 464: ......

Страница 465: ......

Страница 466: ......