HEATER AND AIR CONDITIONING 1A-16

COMPRESSOR OIL

Special refrigeration lubricant should be used in the

system.

This oil is as free from moisture and con

taminants as it is possible to attain by human processes.

This condition should be preserved by immediately cap

ping the bottle when not in use.

See "Air Conditioning System Capacities" for the total

system oil capacity.

Due to the porosity of the refrigerant hoses and con

nections, the system refrigerant level will show a definite

drop after a period of time. Since the compressor oil is

carried throughout the entire system mixed with the

refrigerant, a low refrigerant level will cause a danger

ous lack of lubrication. Therefore the refrigerant charge

in the system has a definite tie-in with the amount of oil

found in the compressor and an insufficient charge may

eventually lead to an oil build-up in the evaporator.

COMPRESSOR SERIAL NUMBER

The compressor serial number is located on the serial

number plate on top of the compressor. The serial num

ber consists of a series of numbers and letters. This

serial number should be referenced on all forms and

correspondence related to the servicing of this part.

INSPECTION A N D PERIODIC SERVICE

PRE-DELIVERY INSPECTION

1. Check that engine exhaust is suitably ventilated.

2. Check the belt for proper tension.

3. With controls positioned for operation of the system,

operate the unit for ten minutes at approximately

2000 rpm. Observe the clutch pulley bolt to see that

the compressor is operating at the same speed as

the clutch pulley.

Any speed variation indicates

clutch slippage.

4. Before turning off the engine, check the sight glass

to see that the unit has a sufficient Refrigerant

charge. The glass should be clear, although during

milder weather it may show traces of bubbles. Foam

in the flow indicates a low charge. No liquid visible

and no temperature differential between compressor

inlet and outlet lines, indicates no charge.

5. Check refrigerant hose connections:

"O" ring Connections - Check torque of fittings as

charted later in this section under "Refrigerant Line

Connections;" retorque if required. Leak test the

complete system.

Hose Clamp Connections - If clamp screw torque is

less than 10 in. lb., retighten to 20-25 in. lbs. Do

not tighten to new hose specifications or hose leakage

may occur. Leak test the complete system.

6. If there is evidence of an oil leak, check the com

pressor to see that the oil charge is satisfactory.

NOTE:

A slight amount of oil leakage at the

compressor front seal is considered normal.

7. Check the system controls for proper operation.

6000 MILE INSPECTION

1. Check unit for any indication of a refrigerant leak.

2. If there is an indication of an oil leak, check the

compressor for proper oil charge.

NOTE:

A slight amount of oil leakage at the

compressor front seal is considered normal.

3. Check sight glass for proper charge of Refriger

ant-12.

4. Tighten the compressor brace and support bolts and

check the belt tension.

5. Check refrigerant hose connections as in Step 5 of

"Pre-Delivery Inspection."

PERIODIC SERVICE

• Inspect condenser regularly to be sure that the fins

are not plugged with leaves or other foreign material.

• Check evaporator drain tubes regularly for dirt or

restrictions.

• At least once a year, check the system for proper

refrigerant charge and the flexible hoses for brittle

ness, wear or leaks.

• Every

6000

miles check sight glass for low refrig

erant level.

• Check belt tension regularly.

INSTALLING CH AR G IN G STATION TO CHECK

SYSTEM OPERATION

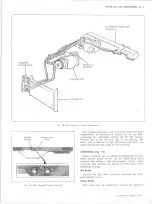

1. Four Season System - The low pressure fitting is

located on the POA valve. The high pressure fitting

is located on the muffler (fig.

25).

NOTE:

The connector assembly consists of in

let (suction) and outlet (discharge) lines with the

freon hoses swaged to the metal lines (fig.

25).

Roof-Mounted and GM Chevrolet Systems - The low

pressure fitting is located on the connector block and

the high pressure fitting on the muffler (fig.

25).

2.

Install Gauge Adapters

J -5 4 2 0

and

J -9 4 5 9

onto the

high and low pressure gauge lines.

3. With the engine stopped, remove the caps from the

cored valve gauge fittings.

4.

Be certain all valves on charging station are closed.

5.

Connect high pressure gauge line to high pressure

gauge fitting.

6.

See Figure

22.

Turn high pressure control

(2)

one

turn counter-clockwise (open).

Crack open low

pressure control (1) and allow refrigerant gas to hiss

from low pressure gauge line for three seconds,

then connect low pressure gauge line to low pres

sure gauge fitting.

7. System is now ready for performance testing.

PERFORMANCE TEST

This test may be conducted to determine if the sys

tem is performing in a satisfactory manner and should

be used as a guide by the serviceman in diagnosing

trouble within the system.

The following fixed condi

tions must be adhered to in order to make it possible to

10-30 CHEVROLET TRUCK SERVICE MANUAL

Содержание 10 1971 Series

Страница 1: ......

Страница 96: ......

Страница 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Страница 120: ......

Страница 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 218: ......

Страница 249: ......

Страница 250: ...EMISSION CONTROL SYSTEMS 6T 4 Fig 3 Combination Emission Control System Routing V8 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 324: ......

Страница 339: ...FUEL TANK AND EXHAUST SYSTEMS 8 15 SPECIAL TOOLS Fig 22 Special Tools 1 J 23346 Fuel Tank Gauge Remover and Installer ...

Страница 340: ......

Страница 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Страница 368: ......

Страница 386: ......

Страница 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 391: ......

Страница 392: ...ELECTRICAL BODY AND CHASSIS 12 6 Fig 5 Rear Lighting Composite 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 409: ...ELECTRICAL BODY AND CHASSIS 12 23 Fig 27 Engine Compartment CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 410: ...ELECTRICAL BODY AND CHASSIS 12 24 18DK GRN 19 Fig 28 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 411: ...ELECTRICAL BODY AND CHASSIS 12 25 Fig 29 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 412: ...ELECTRICAL BODY AND CHASSIS 12 26 fh Ar r kk 4 Fig 30 Engine Compartment C A K A 10 20 CA30 03 z _ ...

Страница 416: ...ELECTRICAL BODY AND CHASSIS 12 30 Fig 34 Engine Compartment CA KA10 20 CA30 04 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 420: ...ELECTRICAL BODY AND CHASSIS 12 34 Fig 38 Engine Compartment C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 422: ...ELECTRICAL BODY AND CHASSIS 12 36 Fig 40 Instrument Panel C A K A 10 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 423: ...ELECTRICAL BODY AND CHASSIS 12 37 Fig 41 R ear Lamps C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 424: ...ELECTRICAL BODY AND CHASSIS 12 38 Fig 42 Engine Compartment CA KA10 20 CAl30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 426: ...ELECTRICAL BODY AND CHASSIS 12 40 Fig 44 Instrument Panel CA KA10 20 CA30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 428: ......

Страница 432: ......

Страница 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 463: ......

Страница 464: ......

Страница 465: ......

Страница 466: ......