HEATER AND AIR CONDITIONING 1A-13

• Flexible hose lines should be inspected at least once

a year for leaks or brittleness. If found brittle or

leaking they should be replaced with new lines.

• Use only new lines that have been sealed during

storing.

• When disconnecting any fitting in the refrigeration

system, the system must first be discharged of all

refrigerant. However, proceed very cautiously re

gardless of gauge readings. Open very slowly, keep

ing face and hands away so that no injury can occur

if there happens to be liquid refrigerant in the line.

If pressure is noticed when fitting is loosened, allow

it to bleed off very slowly.

CAUTION:

Always wear safety goggles when

opening refrigerant lines.

• In the event any line is opened in atmosphere, it

should be immediately capped to prevent entrance

of moisture and dirt.

• The use of the proper wrenches when making con

nections on "O" ring fittings is important. The use

of improper wrenches may damage the connection.

The opposing fitting should always be backed up with

a wrench to prevent distortion of connecting lines or

components. When connecting the flexible hose con

nections it is important that the swaged fitting and

the flare nut, as well as the coupling to which it is

attached, be held at the same time using three dif

ferent wrenches to prevent turning the fitting and

damaging the ground seat.

• "O" rings and seats must be in perfect condition.

The slightest burr or piece of dirt may cause a leak.

• Sealing beads on hose clamp connections must be

free of nicks and scratches to assure a perfect seal.

capped immediately after use.

• When it is necessary to open a system, have every

thing you will need ready and handy so that as little

time as possible will be required to perform the

operation. Don't leave the system open any longer

than is necessary.

• Finally, after the operation has been completed and

the system sealed again, air and moisture should be

evacuated from the system before recharging.

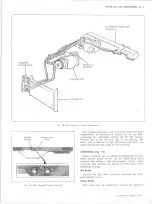

J-8393 C H A R G IN G STATION

The J-8393 Charging Station is a portable assembly of

a vacuum pump, refrigerant supply, gauges, valves, and

most important, a five (5) pound metering refrigerant

charging cylinder. The use of a charging cylinder elim

inates the need for scales, hot water pails, etc.

The chief advantage of this unit is savings. A very

definite savings in refrigerant and time can be obtained

by using this unit. Since the refrigerant is metered into

the system by volume, the correct amount may be added

to the system. This, coupled with the fact that the unit

remains "plumbed" at all times and thus eliminates loss

of refrigerant in purging of lines and hooking-up, com

bines to enable the operator to get full use of all re

frigerant purchased.

All evacuation and charging equipment is hooked to

gether in a compact portable unit (fig. 21). It brings air

conditioning service down to the basic problem of hooking

on two hoses, and manipulating clearly labeled valves.

This will tend to insure that the job will be done without

skipping operations. As a result, you can expect to save

time and get higher quality work, less chance of an over

or undercharge, or comeback.

M A IN T A IN IN G CHEMICAL STABILITY IN THE

REFRIGERATION SYSTEM

The metal internal parts of the refrigeration system

and the refrigerant and oil contained in the system are

designed to remain in a state of chemical stability as

long as pure R-12 and uncontaminated refrigeration oil

is used in the system.

However, when abnormal amounts of foreign materials,

such as dirt, air or moisture are allowed to enter the

system, the chemical stability may be upset. When ac

celerated by heat, these contaminants may form acids

and sludge and eventually cause the breakdown of com

ponents within the system. In addition, contaminants

may affect the temperature-pressure relationship of R-12,

resulting in improper operating temperature and pres

sures and decreased efficiency of the system.

The following general practices should be observed to

insure chemical stability in the system.

• Whenever it becomes necessary to disconnect a

refrigerant or gauge line, it should be immediately

capped. Capping the tubing will also prevent dirt and

foreign matter from entering.

• Tools should be kept clean and dry. This also in

cludes the gauge set and replacement parts.

• When adding oil, the container should be exception

ally clean and dry due to the fact that the refrigera

tion oil in the container is as moisture-free as it is

possible to make it. Therefore, it will quickly ab

sorb any moisture with which it comes in contact.

For this same reason the oil container should be

Fig- 21—

J-8393 Charging Station

HIGH PRESSURE

CONTROL (2)

LO W PRESSURE

CONTROL (1)

FREON

CONTROL

(4)

HIGH PRESSURE

G A U G E LINE

5 LB. C H A R G IN G

CYLINDER

LEAK

DETECTOR

FREON DRUM

CONTROL VALVE

V AC U U M

CONTROL

(3)

LOW

G A U G E LINE

OIL

INJECTOR

10-30 CHEVROLET TRUCK SERVICE MANUAL

Содержание 10 1971 Series

Страница 1: ......

Страница 96: ......

Страница 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Страница 120: ......

Страница 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 218: ......

Страница 249: ......

Страница 250: ...EMISSION CONTROL SYSTEMS 6T 4 Fig 3 Combination Emission Control System Routing V8 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 324: ......

Страница 339: ...FUEL TANK AND EXHAUST SYSTEMS 8 15 SPECIAL TOOLS Fig 22 Special Tools 1 J 23346 Fuel Tank Gauge Remover and Installer ...

Страница 340: ......

Страница 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Страница 368: ......

Страница 386: ......

Страница 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 391: ......

Страница 392: ...ELECTRICAL BODY AND CHASSIS 12 6 Fig 5 Rear Lighting Composite 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 409: ...ELECTRICAL BODY AND CHASSIS 12 23 Fig 27 Engine Compartment CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 410: ...ELECTRICAL BODY AND CHASSIS 12 24 18DK GRN 19 Fig 28 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 411: ...ELECTRICAL BODY AND CHASSIS 12 25 Fig 29 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 412: ...ELECTRICAL BODY AND CHASSIS 12 26 fh Ar r kk 4 Fig 30 Engine Compartment C A K A 10 20 CA30 03 z _ ...

Страница 416: ...ELECTRICAL BODY AND CHASSIS 12 30 Fig 34 Engine Compartment CA KA10 20 CA30 04 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 420: ...ELECTRICAL BODY AND CHASSIS 12 34 Fig 38 Engine Compartment C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 422: ...ELECTRICAL BODY AND CHASSIS 12 36 Fig 40 Instrument Panel C A K A 10 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 423: ...ELECTRICAL BODY AND CHASSIS 12 37 Fig 41 R ear Lamps C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 424: ...ELECTRICAL BODY AND CHASSIS 12 38 Fig 42 Engine Compartment CA KA10 20 CAl30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 426: ...ELECTRICAL BODY AND CHASSIS 12 40 Fig 44 Instrument Panel CA KA10 20 CA30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 428: ......

Страница 432: ......

Страница 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 463: ......

Страница 464: ......

Страница 465: ......

Страница 466: ......