REAR SUSPENSION AND DRIVE LINE 4-11

CO MPONENT PARTS REPLACEMENT

SERIES 10 3300, 3500 LB. CAPACITY AXLES

A N D SERIES 20 5500 LB. CAPACITY AXLES

AXLE ASSEMBLY (EXCEPT 5500 LB. D A N A AXLE)

Construction of the axle assembly is such that service

operations may be performed with the housing installed in

the vehicle or with the housing installed in a holding fix

ture. The following removal and installation procedure

is necessary only when the housing requires replacement.

NOTE:

All Axle attachments are important at

taching parts in that they could affect the perfor

mance of vital components and systems, and/or

could result in major repair expense. They must

be replaced with parts of the same part numbers

or with equivalent parts if replacement becomes

necessary. Do not use replacement parts of

lessor quality or substitute design. Torque

values must be used as specified during re

assembly to assure proper retention of these

parts.

Removal

1. Raise vehicle on hoist.

2. Support rear axle assembly with suitable lifting

device, so that tension is relieved in springs, tie

rod, and shock absorbers.

3. On vehicles so equipped, disconnect tie rod at axle

housing bracket or at differential carrier.

4. Remove trunnion bearing

“ XJ”

bolts from the axle

companion flange, separate trunnion from flange,

position propeller shaft to one side and tie it to

frame side rail.

NOTE:

Secure trunnion bearings caps to trun

nion, using masking tape or a large rubber band,

to prevent loss of bearings.

5. Disconnect shock absorbers at lower attachment

points and position out of the way.

6. Disconnect axle vent hose from vent connector and

position vent hose to one side.

7. Disconnect hydraulic brake hose at connector on axle

housing. Remove brake drum, disconnect parking

brake cable at actuating levers and at flange plate.

Refer to Section 5 for cable removal and brake

details.

8. On vehicles so equipped, check coil springs to make

sure that they are compressed; then on all vehicles,

remove axle

bolt nuts, “ U” bolts, spacers and

clamp plates.

9. Lower axle assembly and remove from vehicle.

Installation

1. Position axle assembly under vehicle and align with

springs or control arms as applicable.

2. Install spacer, clamp plate and

bolts to axle as

sembly, loosely install retaining nuts to

bolts.

3. Position shock absorbers in lower attachment brack

ets and loosely install nut to retain shock.

4. Connect axle vent hose to vent connector at carrier.

5. Connect hydraulic brake hose to connector on axle

housing, connect parking brake cable to actuating

levers. Install brake drum and wheel and tire as

sembly--bleed brakes and adjust parking brake as

outlined in applicable portion of Section 5.

6. Reassemble the propeller shaft to companion flange,

making sure that bearing caps are indexed in flange

seat. Install the torque bearing cap retaining nuts to

specifications.

7. Position vehicle so that weight is placed on suspen

sion c o m p o n e n t s and torque affected parts to

specifications.

8. Lower vehicle and remove from hoist.

AXLE VENT

Replacement

The axle vent system consists of the vent connector,

vent hose and associated attaching parts. When replacing

vent hose make sure that it is routed along original path

in such a manner that the hose is free from kinks or

binds that would restrict air flow. In replacing the vent

connector; pry old connector from carrier, being sure

that entire connector is removed. Tap new connector into

carrier with a soft-faced hammer, prick punch around

edge of hole to insure fit of new connector (fig. 30).

AXLE SHAFT (EXCEPT 5500 LB. D A N A AXLE)

Removal

1. Raise vehicle on hoist. Remove wheel and tire as

sembly and brake drum.

2. Clean all dirt and foreign material from area of

carrier cover.

3. Loosen carrier cover-to-carrier bolts slightly to al

low lubricant to drain from carrier. Remove carrier

cover and gasket.

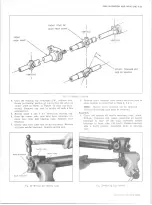

4. Remove the differential pinion shaft lockscrew and

the differential pinion shaft (fig. 18).

5. Push flanged end of axle shaft toward center of

vehicle and remove “ C” lock from button end of

shaft.

6. Remove axle shaft from housing, being careful not to

damage oil seal at end of housing.

Fig. 18— Differential Pinion Shaft Removal

CHEVROLET TRUCK SERVICE MANUAL

Содержание 10 1971 Series

Страница 1: ......

Страница 96: ......

Страница 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Страница 120: ......

Страница 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 218: ......

Страница 249: ......

Страница 250: ...EMISSION CONTROL SYSTEMS 6T 4 Fig 3 Combination Emission Control System Routing V8 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 324: ......

Страница 339: ...FUEL TANK AND EXHAUST SYSTEMS 8 15 SPECIAL TOOLS Fig 22 Special Tools 1 J 23346 Fuel Tank Gauge Remover and Installer ...

Страница 340: ......

Страница 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Страница 368: ......

Страница 386: ......

Страница 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 391: ......

Страница 392: ...ELECTRICAL BODY AND CHASSIS 12 6 Fig 5 Rear Lighting Composite 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 409: ...ELECTRICAL BODY AND CHASSIS 12 23 Fig 27 Engine Compartment CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 410: ...ELECTRICAL BODY AND CHASSIS 12 24 18DK GRN 19 Fig 28 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 411: ...ELECTRICAL BODY AND CHASSIS 12 25 Fig 29 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 412: ...ELECTRICAL BODY AND CHASSIS 12 26 fh Ar r kk 4 Fig 30 Engine Compartment C A K A 10 20 CA30 03 z _ ...

Страница 416: ...ELECTRICAL BODY AND CHASSIS 12 30 Fig 34 Engine Compartment CA KA10 20 CA30 04 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 420: ...ELECTRICAL BODY AND CHASSIS 12 34 Fig 38 Engine Compartment C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 422: ...ELECTRICAL BODY AND CHASSIS 12 36 Fig 40 Instrument Panel C A K A 10 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 423: ...ELECTRICAL BODY AND CHASSIS 12 37 Fig 41 R ear Lamps C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 424: ...ELECTRICAL BODY AND CHASSIS 12 38 Fig 42 Engine Compartment CA KA10 20 CAl30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 426: ...ELECTRICAL BODY AND CHASSIS 12 40 Fig 44 Instrument Panel CA KA10 20 CA30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 428: ......

Страница 432: ......

Страница 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 463: ......

Страница 464: ......

Страница 465: ......

Страница 466: ......